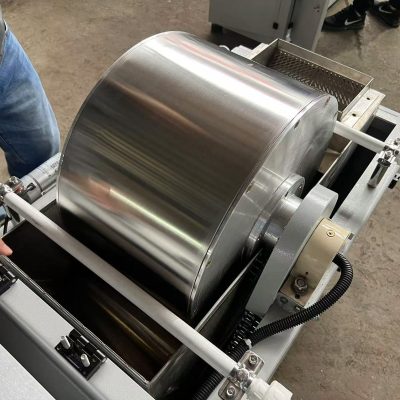

Drum separators are most common low intensity wet magnetic separators. They consist of a rotating non-magnetic drum containing three to six stationary magnets, either permanent or electromagnets, of alternating polarity. Magnetic particles are lifted by the magnets and pinned to the drum and are conveyed out of the field leaving the gangue particles. Water is introduced into the machine to provide a current which keeps the pulp in suspension. Three types of drum separators namely concurrent type, counter-rotation type and counter-current type are in use.

Concurrent type separators are used when clean concentrate is required from relatively coarse material such as heavy medium recovery systems. Counter-rotation type separators arc used in the roughing operation of larger tonnages. Counter-current type separators arc designed for finishing operation on relatively fine material.