The Vezin Sampler can be used for primary or secondary sampling. It is a fully enclosed unit containing a rotating sample cutter that passes at constant speed through the falling stream of slurry or free flowing solids entering it.

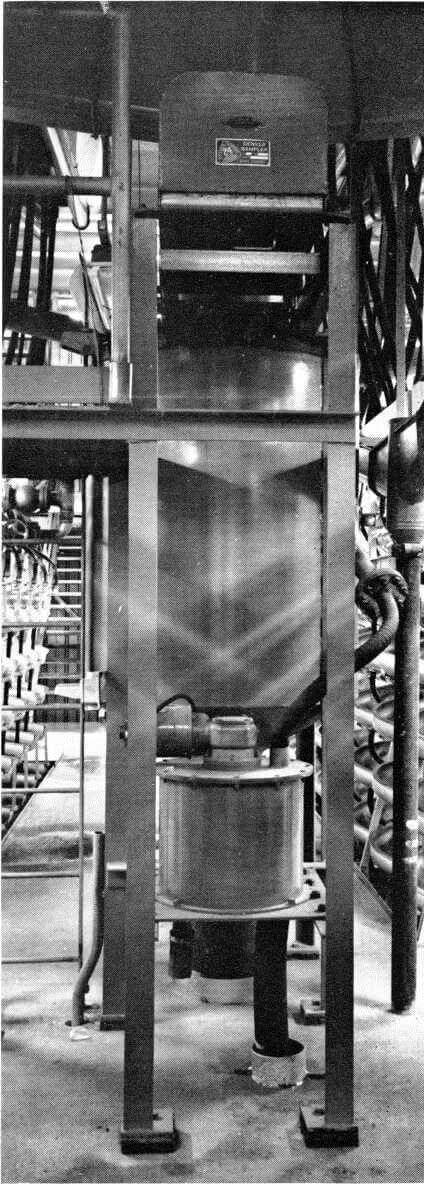

One of the 60 Automatic Samplers recently installed at the Quebec Cartier Mining Company.

Vezin Samplers SPECIFIED FOR QUEBEC CARTIER MINING CO. IN CANADA

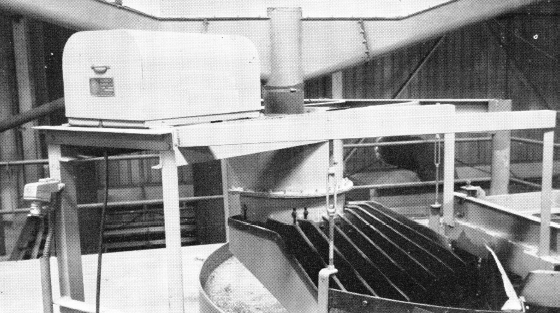

Photo at right shows one of the tailing sample stations at Quebec Cartier in Canada and consists of a primary and secondary unit. With the high flow rate (3975 GPM) and consistent with good sampling practice, a large sample is obtained from the 21″ travel Primary Automatic Sampler. This sample is further automatically reduced in volume to a pailful per shift by a 16″ diameter Secondary Vezin Sampler. The two Samplers are electrically inter-connected.

In operation, both machines are energized simultaneously every 30 minutes as determined by the time switch. At 44 RPM the secondary Vezin Sampler with 4 cutters cuts the falling primary stream a number of times.

Since the stream continues to flow and drain through the hose for a short interval after the primary sampler has completed its travel, the secondary sampler must continue to run for a longer interval to sample all the flow from the primary unit. This is accomplished by a timing relay located in the housing of the first unit.

In all, there are 60 Samplers in the Quebec Cartier circuits. Of these, 36 are the automatic end carriage type samplers and 24 are coupled with 24 secondary Vezin Samplers.

Quebec Cartier Mining Company was recently honored by a special issue of “Precambrian” magazine.

This 2-stage sampling system at Quebec Cartier Mining company consists of Primary Automatic Sampler and Secondary Vezin Sampler. There are 24 of these 2-stage systems at the Quebec Cartier.

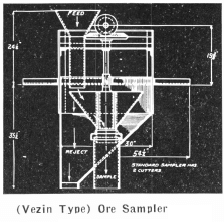

Vezin Sampler

The (Vezin Type) Ore Sampler is one of the most widely accepted automatic samplers in use today. It consists of a sheet steel housing within which operates a cylinder having two or more scoops secured to it. The cylinder and scoops are made of sheet steel and the cylinder is mounted upon a vertical shaft which is driven through bevel gearing by a horizontal shaft having tight and loose driving pulleys or an individual electric motor drive. The entire mechanism is supported in a welded steel frame and the housing forms a hopper at the bottom for receiving rejects from the sampler.

In operation, the cylinder and scoops revolve slowly, causing the scoops to pass under the end of the chute discharging the ore to be sampled. The scoops cut out the sample as they pass through the stream of ore. The sample passes through the revolving element and then is conducted by a pipe or chute to units which reduce or prepare the sample for testing or study. The rejects fall into the hopper from whence they are returned to the circuit.

This sampler can be furnished with a rotating disk feeder mounted on the same shaft, thus giving a uniform feed for sampling. Several disks and cutters can be mounted on the same rotating shaft, thereby simplifying the plant layout.

We build these samplers to handle any practicable size of material and to cut almost any size of sample desired. Recommendations and detailed information on (Vezin Type) Ore Samplers will be gladly provided upon request.