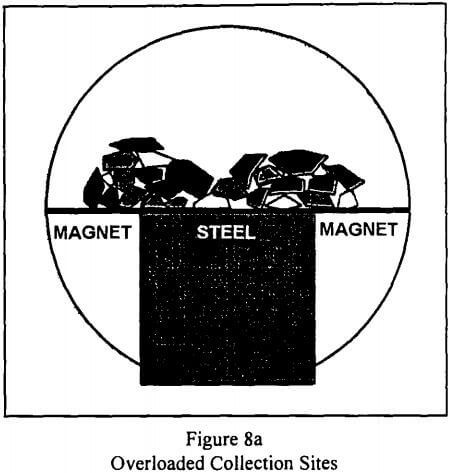

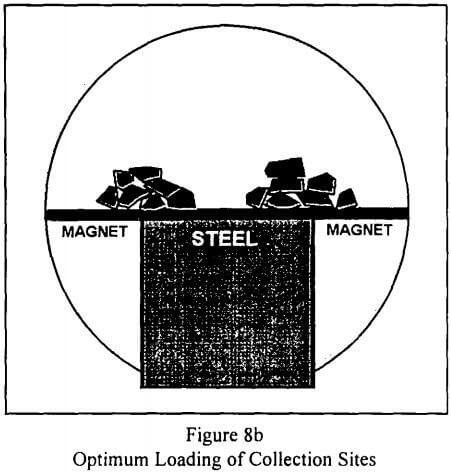

The first known attempts to apply a REM roll separator to a heavy mineral sands application were made in South Africa and Western Australia in 1985. At that time, an ilmenite beneficiation process, which was normally achieved with cross-belt separators, was tested with a full-size machine. The performance was not good because only a single separation pass flow sheet was used. Furthermore, as a large amount of magnetic material needed to be removed (over 85% of the feed), and only low roll speed was applied, the result was an excessive loading of magnetic particles on the magnetic collection sites, see illustrations in Figures 8a and 8b. Since the first generation REM rolls had only 20% of the roll surface available for attracting magnetic particles, it is easy to realize that a large amount of nonmagnetic particles could be trapped among the highly magnetic ilmenite particles as illustrated in Figure 8a.

By the time this author became involved in the Australian trials, the time had run out to take any corrective actions regarding test procedures. A year later, new testing under proper guidance was initiated with outstanding results. What was different? First of all, it is well known that if too great magnetic force versus the counteracting inertia forces (“centrifugal forces”) is applied, the magnetic particles are attracted too strongly and will lock in some nonmagnetic particles as illustrated in Figure 8a. That was easily remedied by using much higher roll speeds and a

thicker belt, see Figure 8b, which of course has more attractive life time than thin belts. High roll speeds translates into much higher feed rate capability as well.

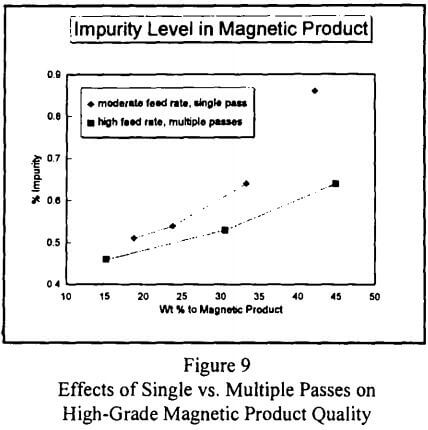

It is also established that it is usually far better to use multiple pass separation than a single pass, when a large amount of material should be removed from the

feed stream. Figure 9 shows that a multiple-pass separation provides a more selective separation compared to a single pass, even if the feed rate is increased in proportion to the number of separation

stages used.

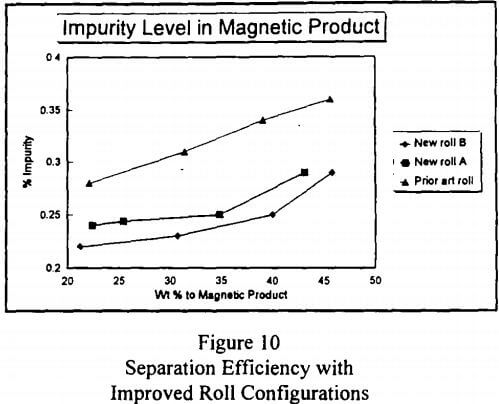

By optimizing the roll configuration to a higher level, the performance was further enhanced last year (1997), as shown in Figure 10. When the company, Westralian

Sands Ltd., decided to proceed with a full-scale operation and replace the cross-belt separator plant, the optimized roll type (class 1) was selected. In fact, in some heavy minerals processes, far superior performance has been achieved than with any other type of high-intensity magnetic separator. Unfortunately, very little data has been released for publication.

A similar optimization effort has already led to major mineral sands processing installations in South Africa. It is now well established that processing of every ilmenite, rutile, zircon and monazite material from different sources may

warrant an optimization study. The one- size-fits-all mentality is still lingering, but it is giving way to the engineered approach. Only one major case is known where both REM drum and roll separators were installed, but no optimization effort was done. The client would not accept separators using belts (except in situations when the drum separator would have inadequate strength), despite the 10 years excellent track record at Westralian Sands Ltd. Class 1 REM roll separators equipped with a belt tracking system that keeps the belts running 12 to 18 months would have been a superior alternative to drum separators in this case. Insufficient plant performance is now reported.

At another plant with an identical process need, the class 1 roll separator was reported to have 99+% efficiency, while the drum separator tested in this application had 88%.

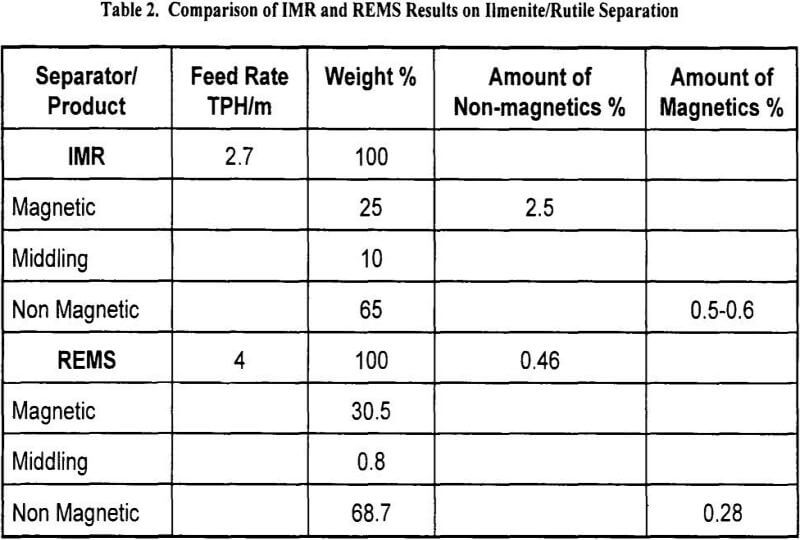

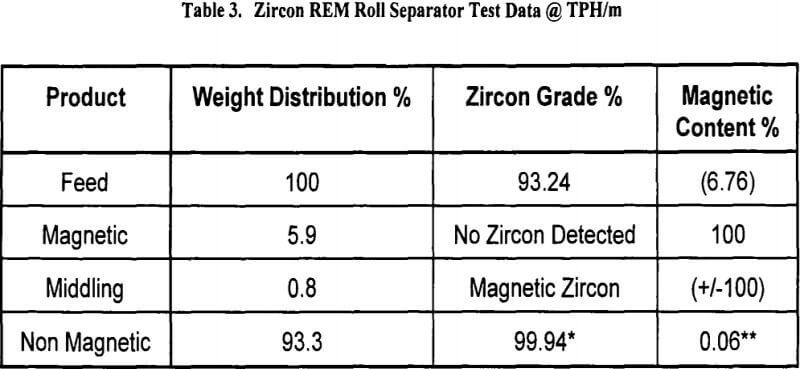

Small-scale use of both REMS roll and drum separators has become common in the heavy mineral sands industry, mainly in South Africa, but also in Australia. Usually, these separators were applied to solve bottle necks in the process flow sheets, or to modify the product quality after processing with conventional equipment, such as cross-belts or induced magnetic roll separators. The small size and high capacity capabilities were attractive for such retrofits. One of the first installations of this nature was at RZ Mines in Australia. The conventional IMR separator performance compared to the earliest type of REM separator is shown in Tables 2 and 3.

As mentioned, the graph in Figure 10 shows recent improvements in processing heavy minerals by applying more advanced magnetic roll configurations than the typical rolls provided by class 2 and 3 roll separator makers. In fact, in some heavy mineral sands processes, far superior performance has been achieved than with any other type of high-intensity magnetic separator (other REM roll and drum separators, induced roll and cross belt separators). Unfortunately no data has been released for publication. It may be sufficient to mention that in one such case, a three-fold increase in production of on-spec product resulted from installation of class 1 separators.

One new entry in the heavy mineral sands industry provided preliminary test data. We may use the results of initial testing to illustrate the information that may be obtained from a few preliminary, low cost and quick tests. Optimization of roll and flow sheet configurations would be the next step, which would yield even more interesting performance. Let us first look at various size fractions of ilmenite gravity concentrate.