Laboratory Solvent Extraction and Stripping Units Evaluate Process Prior to Commercial Size Installation

Laboratory Solvent Extraction and Stripping Units Evaluate Process Prior to Commercial Size Installation

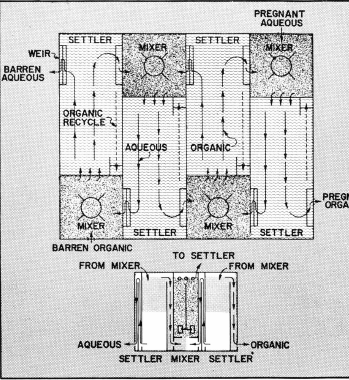

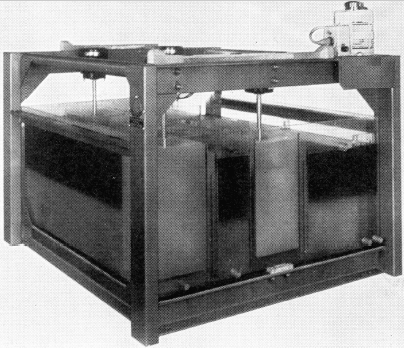

The Laboratory Solvent Extraction and Stripping Units provide a completely visual control of the solvent extraction process. There is great flexibility in regulating speed of agitators, recirculation of the organic phase or aqueous phase. The system provides counter-current flow. No pumps are needed. With controlled rates of feeding in the organic and aqueous phases the unit is self-operating. This results in a versatile unit, ideal for research, educational and process improvement purposes.

Dimensions of 2′-10¾” x 3’3¾” x 2′ 8″ high include the motors and power-stat which regulates the agitator speed. The unit is mounted in a compact structural frame which protects the plastic tank during shipment.

Capacity depends on the specific problem. Units are of acid-proof construction and are available for both the extraction and stripping circuits. They are available in 3, 4, 5 and 6 stage units. Mixer compartments have a retention volume of 2 gallons and the settlers have a settling area of 1 1/8 sq. ft., while the last stage settler has an area of 2 sq. ft. Capacity of the unit ranges up to 1 g.p.m. flow of aqueous.