Table of Contents

The Core-Oven tests here described were made to obtain information regarding costs, efficiency, etc. of baking cores in an oil-fired oven, and two electric ovens, which were installed, early in 1920, in the core room of The Ohio Brass Co. and were used almost continuously during the rest of that year. Operating costs were rather high so a complete test was undertaken early in the last century.

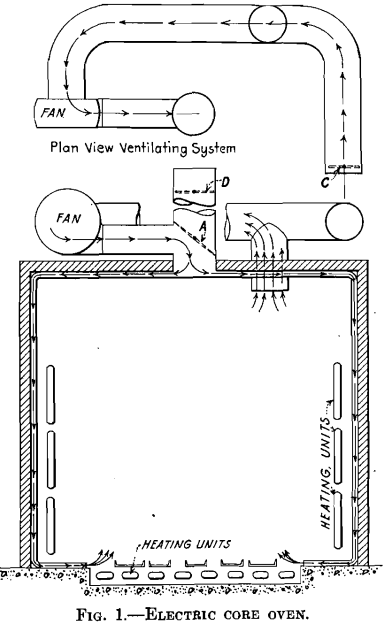

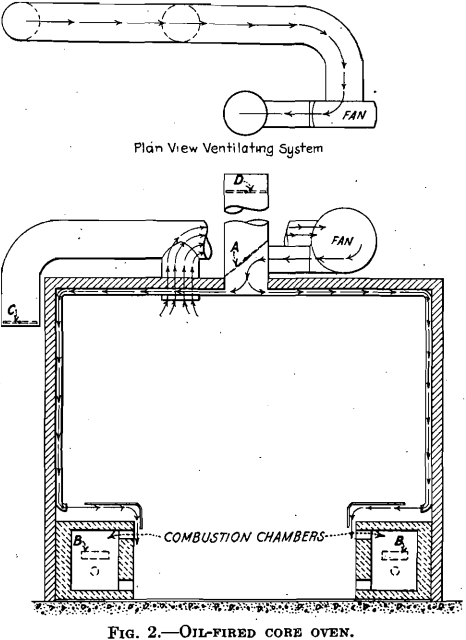

The ovens will be referred to as Nos. 1, 2, and 3. Nos. 1 and 2 are electric ovens of different makes while No. 3 is an oil-fired oven made by the firm that made No. 2. The three are equipped with similar ventilating devices. They have full-height doors at front and rear. The cores are placed on iron racks, which are lifted by Cowan trucks and rolled into the ovens through the front doors. When baked, they are removed through the rear doors. Fig. 1 shows the general plan of the electric ovens while Fig. 2 shows the plan of the oil-fired oven.

Oven No. 1 is 91 in. (231 cm.) wide, 83 in. (210 cm.) high, and 79 in. (200 cm.) deep, inside measurements. The walls are constructed in panels about 18 in. (46 cm.) wide and 4 3/16 in. (10.6 cm.) thick, packed with blocks of insulating material and covered with sheet iron. The concrete floor on which the ovens set is 13 in. (33 cm.) thick. A recess about 5 in. (13 cm.) deep was cut in the floor to provide room for the heating units. Channels and plates supported on I beams serve as supports for the trucks and racks.

The ventilating system consists of a Sirroco No. 1½ fan, connected so as to draw air from the top of the oven or from the room, through damper C, and to deliver it either to the bottom of the oven or to the floor; the delivery is controlled by the vane A. The fan and pipes are covered with ¼ in. (6.3 mm.) asbestos cement lagging.

The heating units have a capacity of 94.4 kw. and are located along the sides and in the floor. The temperature is controlled by a “Tycos” thermostat; there is also a glass thermometer on one of the doors.

The inside dimensions of oven No. 2 are each about 1 in. (2.5 cm.) shorter than those of No. 1. The walls are 2 3/16 in- thick and built of 2 in. of asbestocel covered on each side with 1/8 in. of Firefelt and sheet iron. The heating units are of the same capacity and are located in the same manner as in oven No. 1. The ventilating system and temperature control are also the same.

Oven No. 3 is 102 in. (259 cm.) wide, 85 (216 cm.) high, and 78 in. (198 cm.) deep, inside measurements. The wall construction is the same as in oven No. 2; the floor is of ½-in. (12.7 mm.) steel plate laid on the concrete floor. There are two combustion chambers, one on each side of the doors; they are 21 in. (23 cm.) high, 21 in. wide, and extend the length of the oven. There are several openings along the side to permit hot gases to pass into the oven. An Anthony ¾-in. high-pressure burner is located at the front of each combustion chamber. Fuel oil is supplied at a pressure of about 70 lb. and air at about 60 lb. The ventilating system is similar to that of the other two ovens; the recirculated air, however, is delivered about 3 in. above the combustion chambers on each side and directed toward the middle of the oven. Sheet iron is supported over the chambers in such a manner as to direct the air toward the floor.

The oil-fired oven installation, however, was by no means ideal. The structure of the floor and supports under the ovens was such that the location of combustion chambers under the surface could be accomplished only with difficulty. For this reason we adopted the present system, which has not proved fully satisfactory and is to be reconstructed in the near future.

The cores baked in the tests were the regular run of cores used in our foundry. They consisted largely of valve bodies up to 3 in. in size, valve fittings, and overhead-trolley fittings. They varied in weight from a fraction of an ounce to a couple pounds but averaged about 3½ oz. They were composed of lake and molding sands and sand-blast dust with linseed oil and a small quantity of glutrin as binder.

Each oven was carefully studied to determine the best method of manipulation, heat absorption, heat losses, etc. Test bakes were then made and analyzed as regards heat distribution and costs.

A Leeds & Northrup potentiometer and seven thermocouples located at various points in and about the oven were used to study temperature distribution. A Pitot tube was placed in the flue to measure the volume of gases passing out. Power consumption in the electric ovens was registered by kilowatt-hour meters and an especially designed oil-measuring apparatus was used to measure the fuel-oil consumption in the oil-fired oven.

ELECTRICAL CORE OVENS

Radiation and Other Unavoidable Losses

Under this heading is included all unavoidable leakage of heat that occurs while the oven is closed as tight as is practicable. It was determined by saturating the oven with heat at the average baking tempera

ture (400° F. by the door thermometer) and then measuring the power required to maintain that temperature with the oven completely closed. It was found that oven No. 1 consumed 19.7 kw. and No. 2 consumed 24.0 kw. The hottest points were along the sides of the ovens directly in front of the heating units, while the coolest points were near the floor. The thermostat was set to “kick in” and “kick out” within 10° F. but a variation in temperature of 40° was observed at points directly in front of the heating units, indicating that much heat is passed to the cores by direct radiation.

Heat Losses Under Operating Conditions

Inasmuch as operating conditions would not always permit the oven to be entirely closed, it was thought advisable to determine the heat losses due to ventilation. The measurements were made by setting the dampers, fan, etc. as desired and then observing the power consumption required to maintain the oven at baking temperature. The power consumption was in most cases greater than the figure observed when the oven was entirely closed. This was due to the loss of hot air through the flue and the admission of cool air either through damper C or about the doors. From this excess loss, the change in temperature of the air entering and leaving the oven and the specific heat of air we were able to estimate the weight of air passing through the oven per minute. A fair check on several of these determinations was obtained by measuring the air flow in the flue with the Pitot tube thus practically confirming the method used for handling the heat losses.

Greater uniformity of temperature could be obtained in the electric ovens by operating the fans and recirculating the air but a certain amount of hot air leaked past the dampers and up the flue, and more power was consumed. Under these conditions, about 1.9 lb. of air per minute passed through oven No. 1 and 22.5 kw. were consumed; for oven No. 2 the figures were 5.4 lb. and 32.2 kw., respectively. Evidently, considerable air was supplied to the cores even when all dampers were closed. Upon setting damper A partly to exhaust and partly to recirculate the air the temperatures were less uniform and much more power was consumed. When the damper was set to exhaust the air up the flue, the power consumption for each oven was about 40 kw., indicating that about 38 lb. of air were being drawn through the ovens each minute.

Heat Absorption

Tests were run to determine the quantity of heat absorbed by each oven in coming up to 400° F. from room temperature. The absorption of heat continued after the door thermometer registered 400°, so the power absorbed in holding this temperature was measured until the outer wall temperature reached an equilibrium, indicating that the walls were saturated. The tests were run with the ovens entirely closed. It was found that 48.0 kw.-hr. were required to heat oven No. 1 from room temperature to 400° F. in 28.5 min. An equilibrium was not reached, however, until 3 hr. later; during this period 8.4 kw.-hr. were absorbed in addition to the 19.7 kw.-hr. required each hour to compensate for radiation loss. Oven No. 2 consumed 46.0 kw.-hr. in coming from room temperature to 400° F. in 27 min. As in the case of No. 1, equilibrium was not reached for about 3 hr., during which time 10.0 kw.-hr. were absorbed in addition to the 24.0 kw.-hr. required each hour to compensate for radiation loss. Oven No. 2 required slightly less power and rose in temperature slightly faster than No. 1, probably on account of its light construction. Its radiation losses, however, were greater.

Bakes

In baking cores, the electric ovens were handled as follows: They were heated to at least 450° F. and the loaded racks run in; this caused the temperature to drop 75° to 100°. The power was left on until the door thermometer indicated 425°, when it was cut off for the rest of the bake, which was completed in from 60 to 70 min. total time. Small bakes did not require the operation of the fan, but for the average bake, say 300 lb. and larger, the fan recirculated air while the temperature was rising above 400° F.

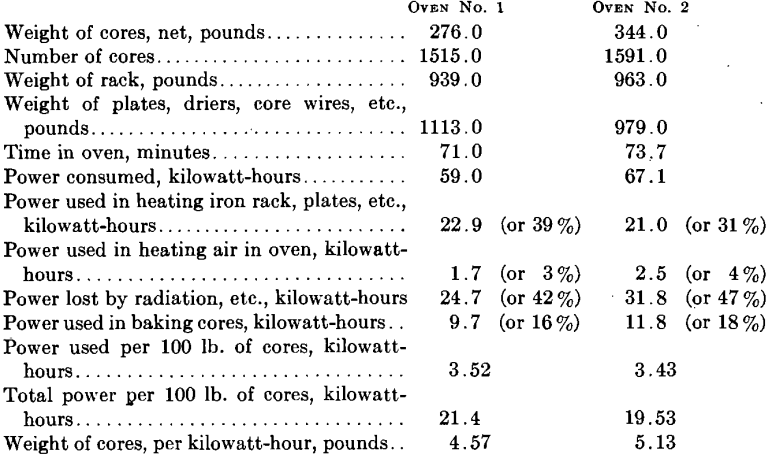

Three special bakes were made in each oven in an effort to determine just what became of the power consumed. Evidently part was used in heating the iron racks, plates, etc. from room temperature to the temperature at which they left the oven, part heated the air that entered the oven when the racks were put in and taken out, part heated the air drawn through the oven by the ventilating system, and part was radiated, while the rest was probably used in actually baking the cores. For each of the test bakes, the ovens were held at 400° before putting in the racks and were brought back to 400° immediately after the racks were removed. Time was measured from the entrance of a rack until the temperature was back to 400°, after its removal, and the power consumption, heat losses, etc. over the same period were considered. Following are the average figures per bake for each oven:

It should be noted that the total power consumption per hundred pounds of cores baked was lower in the case of oven No. 2 because the cores were larger and heavier loads were baked at a time. The heat actually used by the baking cores was practically the same in each case.

OIL-FIRED CORE OVEN

This oven was more difficult to operate than the electric ovens, on account of the nature of the fuel and the attendant difficulties in ventilation and in heat measurement, so the results were not as uniform as

desired. The fuel oil had a calorific value of about 19,560 B.t.u. per lb.; it was calculated that the available heat value of each gallon was about 138,800 B.t.u., which is equivalent to 40.6 kw.-hr. electric energy. The average baking temperature, as registered on the door thermometer, was 425° F.

Radiation and Other Unavoidable Losses

It was necessary to ventilate the oven and keep the fan going while the burners were operating so the radiation loss could not be determined by the method used with the electric ovens. The method used consisted in heating the oven from 382° to 470° F., measuring the oil consumption, then shutting off the burners, closing up the oven, and measuring the time required for the temperature to return to the original reading. The dampers were open and the fan was exhausting air up the flue while the burners were operating, so the fuel consumption necessary to balance the losses and hold the temperature at 425° had to be determined; this was found to be-1.83 gal. per hr. To heat the oven from 382° to 470° in 32 min. 2.18 gal. of oil were consumed; the heat was lost by radiation, etc., with the oven closed, in 99 min. By calculation, it was found that radiation and other unavoidable losses, with the oven completely closed and at a temperature of about 425° F., were equivalent to about 0.736 gal. of fuel oil.

Heat Losses Under Operating Conditions

The burners operated best when the dampers were open and the fan was exhausting; then they consumed 1.83 gal. per hr. of oil, as mentioned. Attempts were made to obtain a more uniform temperature throughout the oven, by recirculating part of the gases and exhausting part, by closing the fresh-air inlet C and setting damper A in notch 3. This did not interfere seriously with the operation of the burners when the combustion chambers were hot and resulted in a lower heat loss; under these conditions 1.45 gal. of oil were consumed per hour. Nothing was gained, however, in uniformity of temperature; in fact, there was more variation. When the attempt to recirculate a larger proportion of the gases was made, the burners gave trouble. Evidently, considerable ventilation is necessary.

Heat Absorption

About 5 gal. of oil were required to bring the oven from room temperature to 450° F.; this was accomplished in about 50 minutes.

Bakes

Considerable trouble was experienced in obtaining a uniform bake, as the heat issuing from the vents in the combustion chamber struck the cores and burnt those near the edges of the racks while others farther in were green. Bricks were removed from the upper course, at intervals of about 1 ft., and iron sheets placed so that the air from the ventilating pipes was directed down over the edge of the chamber and up through the racks and cores. The fan was set to exhaust and all dampers were open during the early part of the bake; but it was found advantageous to close damper C and partly recirculate during the latter part of the time when the burners were on. When the temperature, as shown by the door thermometer, reached 450° F., the burners were shut and the oven was completely closed.

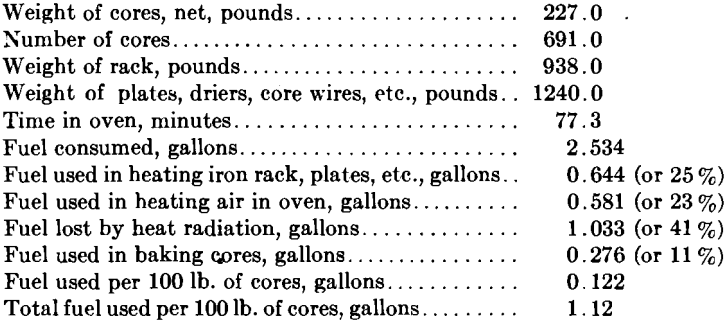

Three bakes were made and analyzed as in the other tests; the averages of the results obtained were as follows:

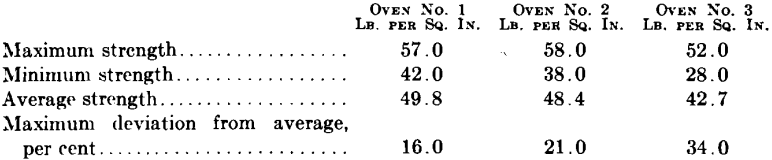

UNIFORMITY OF BAKES IN THE THREE CORE OVENS

This test was run simultaneously in the three ovens, so as to make it strictly comparable. Thirty-nine plates of test cores, five cores on each plate, were made from the same batch of core sand. Thirteen plates were placed on each of three racks together with the regular loads of cores; one was placed on each corner of the upper, middle, and lower shelves and the other in the center of the middle shelf. The racks were then put into the ovens and baked under the best conditions we could obtain. The cores were then broken on a Wadsworth core-testing machine and the average strength of each plate was determined. Following are the results:

The cores on the lower shelf of oven No. 3 were overbaked by the hot gases issuing from the combustion chambers: this difficulty was experienced in nearly all the bakes in this oven. After sheets of metal were placed on the edge of the second shelf, so as to protect the lower shelf, none of the cores were burned but a few in the center came out a trifle green.

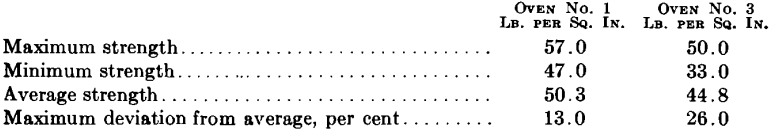

The test was then repeated using only the upper and middle shelves of ovens Nos. 1 and 3; following are the results:

The tests indicate that greater uniformity can be obtained in the electric ovens and the cores are probably a little stronger than in the oil-fired oven.

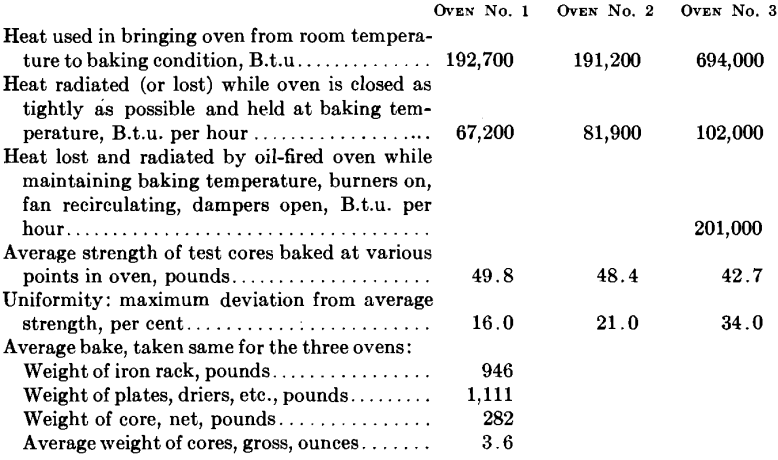

COMPARISON OF CORE OVENS

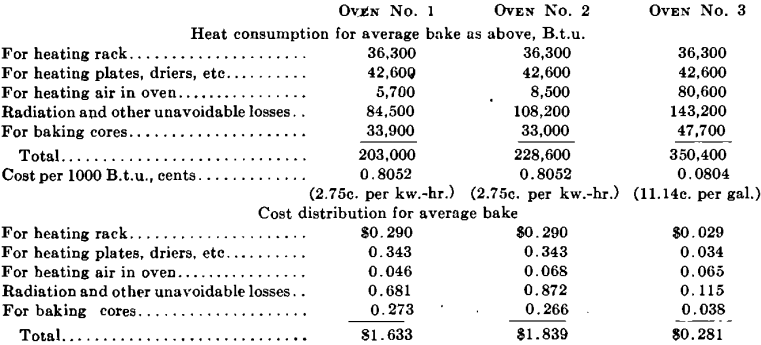

The analyses of bakes given are not directly comparable because racks of different weights and batches of cores of different size and weights were used. The figures below show an average bake and the heat consumption based on such a bake. They are, therefore, a fair comparison of the three ovens.

The factors other than cost of power or fuel that must be considered in comparing the ovens are uniformity and quality of bake, together with labor requirements for operation. The figures given show that more uniform bakes were obtained in the electric ovens. Work was rather slow in the core room when the tests were made so cores varying greatly in size were baked together on the same rack. Fairly uniform bakes, however, were obtained in oven No. 1 but trouble was experienced in the oil-fired oven. Even when cores of uniform size were put on the rack, there was a tendency to burn those on the outer edges of the lower shelf while those in the middle were green. Sheets of metal hung so as to protect this shelf from the direct heat failed to remedy the condition entirely so we quit using the lower-shelf of the racks baked in this oven. Fairly uniform bakes were then obtained.

Core losses in ovens Nos. 1 and 3 were observed for comparison. Of 27,000 cores observed, 0.05 per cent, of those baked in the electric oven were burned and none came out green, while 1.95 per cent, of those baked in the oil-fired oven were burned and 2.14 per cent, came out green. This amounted to a loss, of 30 or 40 cents on an average for each rack baked in the oil-fired oven against less than 1 cent for the electric oven.

The labor requirements for the oil-fired oven were much greater than for the electric ovens. The burners operated on high-pressure air and oil and required considerable attention to obtain the proper mixture for a clean hot flame; slight variations in pressure frequently extinguished the flames. On the other hand, the thermostat on the electric oven could be set to “kick out” at the desired temperature and little attention was required; in, fact racks of cores were baked with no attention being given the oven from the time the rack was run in and the power turned on until within a few minutes before it was removed. One man could handle seven or eight electric ovens while the same labor could handle not more than three oil-fired ovens of the type installed. At the wage paid to the oven tender, this made a difference in tending cost of between 15 and 20 cents per bake in favor of the electric oven.

The noise and smoke from the oil-fired oven are also worthy of consideration. With two burners going, it was almost impossible to converse in the core room. Although when properly regulated, smokeless flames can be obtained from the oil burners, some smoke is almost certain to be made during the course of a bake. This leaves a dirty deposit on the cores, plates, rack, etc. which is a nuisance.

CONCLUSIONS

From the foregoing observations and data, we would conclude that power or fuel costs are decidedly in favor of the oil-fired oven while other considerations such as quality and uniformity of bake, core losses, convenience and cost of tending, cleanliness and noise are decidedly in favor of the electric ovens. Taking into consideration the higher losses in the oil-fired oven and the extra labor cost, the oil-fired oven cost about 10.80 per bake as compared with $1.63 for the electric oven No. 1. All of these considerations are based on the equipment and installation we now have and the present methods of manipulation, both of which we are trying to improve.

DISADVANTAGES OF ELECTRIC CORE OVENS

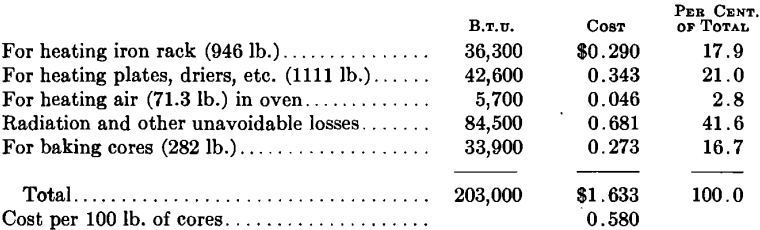

The test has shown that in the case of the better of the two electric ovens the heat and cost distribution on an average bake was as follows:

Only 16.7 per cent, of the heat is used for baking cores, the other 83.3 per cent, heats iron racks, plates, etc., or is lost into the room and up the flue. Some of this, however, is absolutely necessary. Plates and driers are indispensible, the ovens must be ventilated while hot in order to produce a good bake and some heat is certain to be lost through the walls and doors. But we believe that much of the heat consumption with its entailing cost is quite unnecessary, and can be saved by proper design. So long as oil or gas is used as the source of energy, the cost per B.t.u. is so low that these losses are hardly worthy of consideration, but with the high cost of electric energy, a great deal more care must be given to design and construction if economy is to be obtained.

Heating Rack

The racks furnished with the electric ovens averaged about 1000 lb. each. The weight was considerably reduced by removing all the tubular supports that could be spared, but even with this lighter weight the racks absorbed used 17.9 per cent, of the heat used for a bake. By using lighter angle iron, seamless tubes, etc., the weight could certainly be reduced 20 to 30 per cent, more without reducing their strength to the danger point; each 100 lb. of iron thus saved would mean a saving of 3 cents per bake in the electric oven.

Heating Plates, Driers, etc.

The same argument applies to plates and driers. The plates used in the test weigh from 20 to 30 lb. each. We are now trying a few plates made of No. 14 sheet iron stiffened with light angle iron; these plates weigh about 8 lb., thus saving of 60 to 70 per cent, in weight. Several driers, too, have been redesigned with a saving of 50 per cent, in weight. Such savings on the average rack of cores, plates and driers used in the test would mean a saving of about 20 cents per bake.

Heating Air in Ovens

Experiments conducted in our laboratory have shown that at least 4.5 lb. of air should be supplied during a bake for each pound of linseed oil in the cores; more air does no harm so far as the strength of the cores is concerned but requires a useless expenditure of heat energy. The average bake referred to above contains between 5 and 7 lb. of linseed oil and hence would actually require only 25 or 30 lb. of air. Evidently the air in the oven when the rack was placed there together with that which leaks in around doors and enters when doors are opened to examine the cores, is sufficient for a proper bake, so no additional ventilation need be supplied unless heavier bakes are made.

Radiation and Other Unavoidable Losses

While these heat losses were unavoidable in the present installations, they could be materially reduced in a properly designed oven. The loss of 84,500 B.t.u. per hr. from an electric oven costs about $0.68 each hour in addition to the discomfort caused to those working in the room. The construction of the ovens tested may be fairly satisfactory so long as cheap fuel is burned, but it is far from economical when the more expensive electric energy is used. Greater care must then be given to door and damper construction, with view to cutting down heat loss due to air circulation, and effective wall insulation must be provided to cut down losses by conduction. The temperature observed at various points on the outer surface of oven No. 1 ranged from 100° to 180° F., depending on proximity to through iron. Taking the temperature of the entire surface at this lowest figure, it indicates that in a year of 275 working days at least 25,000,000 B.t.u. are lost, costing for electric energy about $200.

Baking Cores

The tests indicate that about 2000 B.t.u. are required to bake each 100 lb. of green core sand. It is highly probable that this figure cannot be reduced as it depends on the binder used and the quantity of moisture in the green sand. By so arranging the oven and rack that larger loads may be baked at a time, it should be possible to increase the percentage of total heat used in actually baking cores and thus make a saving.

The figures and suggestions presented above indicate that there is a vast field for improvement in electric ovens—a field that is of growing importance because of the increasing use of electric energy for industrial heating.