Table of Contents

It is twenty years since the writer made his first molybdenum steels and others were making them commercially five years earlier but the prevailing opinion seems to be that molybdenum steels are new; from time to time the daily press speaks of important discoveries in Europe and intimates that American steel makers have much to learn in regard to alloy steels. The earlier experiments were largely confined to the use of relatively high percentages of molybdenum in tool steels and permanent magnet steels. Recent developments deal with the types of alloy structural steels used for airplane, automobile, and other engineering requirements; in these, the molybdenum content is usually less than 1 per cent. The earlier types generally have been unsuccessful commercially, but the newer types of steels are becoming of increasing importance.

The war showed our dependence on foreign sources for alloying metals; molybdenum alone is widely distributed in the United States and seemingly abundant. Many deposits are not now of commercial interest, owing to location and relatively small amount of ore available, but other deposits are being developed and a stable source of supply seems well assured.

In tool and magnet steels, it was early found that 1 part of molybdenum was equivalent to from 2 to 2.5 parts of tungsten. The permanent magnet steels investigated by Madame Curie, in 1898, contained from 3.36 to 4.05 per cent, molybdenum; in 1902, Dr. E. L. French and the writer thoroughly tested steels containing from 2.0 to 4.0 per cent. These steels gave satisfactory tests for permanence, but were low in residual density and much more sensitive to hardening than the corresponding tungsten products. We discontinued work with them, therefore, and have no advice that such steels have been used commercially here or abroad.

Prior to the development of the Taylor-White process and the modern high-speed steels, air-hardening steels were in general use. These were high in carbon and usually contained tungsten and chromium, the latter having replaced the manganese of the original Mushet air-hardening steels. Later, the tungsten content was frequently replaced by molybdenum. An air-hardening steel largely used had the following analysis: carbon, 1.75 to 2.00 per cent.; molybdenum, 3.75 to 4.25 per cent.; chromium, 3.75 to 4.25 per cent.

In the earlier years of the twentieth century, high-speed steels quickly displaced the air-hardening steels. Most of the manufacturers confined their efforts to tungsten-chromium combinations, but in America determined efforts were made to use molybdenum instead of tungsten. At the time that one European metallurgist was claiming that steel containing over 6 per cent, molybdenum could not be rolled, we were commercially rolling large quantities of a steel containing over 9 per cent, molybdenum and had successfully rolled steel containing up to 15 per cent. The use of molybdenum above 6 per cent, was patented, as was the use of vanadium with either tungsten or molybdenum in high-speed steel. So far as molybdenum was concerned, the manufacture of these steels was discontinued almost before the patents had been allowed. One of these patents has now expired, but “discoveries” of chrome-molybdenum- vanadium steel and molybdenum-vanadium steel for high-speed purposes were recently announced. Both of these types of steels were made and abandoned nearly 20 years ago, as they were found, after very exhaustive experiments and tests, to be unsatisfactory both to manufacturer and in use. Occasionally these steels gave extraordinarily good service, as measured by the standards of that time, which were much below the present standards of the leading high-speed steels. However, notwithstanding the discouraging results of the earlier experiments, the writer has felt that some time we should have to use molybdenum, due to shortage of tungsten, or for other economic reasons, and from time to time during the past 20 years we have repeated our experiments with these steels, with the hope that the general advancement in the art of manufacture might help us to overcome the earlier difficulties and objectionable features.

Why molybdenum is added to steel

One of the principal difficulties with molybdenum in high-speed steel is its tendency to volatilize at the high temperatures necessary in the working and hardening of the steel. Indeed, it is possible to detect high molybdenum steels under the hammer by the light yellow smoke arising, which is probably due to the oxide of molybdenum.

After prolonged or excessive heating, a well-defined zone on the outside of the bars or tools is entirely different from the interior in structure, and as a result, finished tools, such as drills and cutters, which cannot be given the grinding permissible with lathe tools are not satisfactory; this has greatly limited the use of molybdenum high-speed steels. Both vanadium and cobalt have been tried in an endeavor to overcome this difficulty. Recently it was stated that cobalt and vanadium are “stabilizers” for molybdenum, but the writer has seen no evidence to confirm these claims. On the other hand, molybdenum high-speed steel containing either or both of these elements has shown the defect in a marked degree. Some experiments now in progress promise more satisfactory results but it has not been determined whether our “stabilizer” in any way impairs the cutting qualities.

Cobalt-molybdenum-vanadium high-speed steel was made and abandoned in America before the beginning of the European war, for it was found inferior to the regular tungsten-vanadium steel products with or without cobalt. After reading recently that cobalt-molybdenum- vanadium high-speed steel was the latest foreign contribution to tool- steel metallurgy, some of the cobalt-molybdenum-vanadium material made in 1914, some ingots made along similar lines in 1919, and some of the European steel were used in exhaustive and carefully conducted tests made by the Halcomb Steel Co., in which the leading brands of American and foreign manufacture were used. The molybdenum products failed to give satisfactory results and were rated much below the standard tungsten high-speed steels on the market today.

For the modern developments in the use of molybdenum, we are greatly indebted to C. Harold Wills, of Marysville, Mich. Having become convinced that there was abundant ore in this country, he experimented with molybdenum in a great variety of combinations. Much has been published regarding the physical properties and suggested types of molybdenum-alloy steels but we would refer to the papers by Dr. Geo. W. Sargent, J. D. Cutter, and Chas. McKnight, Jr., the booklet entitled “Molybdenum Commercial Steels” by the Climax Molybdenum Co. and the booklet of the Crucible Steel Co. of America entitled “Almo Steels.” While much of this material is propaganda, it is based on experiments made in our own laboratories and plants, in those of the Carbon Steel Co., United Alloy Steel Co. and by Messrs. Wills and Chandler, formerly with the Ford Motor Co. The paper by Doctor Sargent refers to the work of Guillet, Saladin, Swinden and Giolitti in reference to prior use and manufacture of chrome-molybdenum steels of somewhat similar types to those in which interest is now centered. Mr. Cutter’s paper proposes the use of a merit index for the comparison of different steels, and makes use of a formula in which the elastic limit, ultimate strength, elongation and reduction are all taken into consideration. A similar suggestion appears in the booklet “Almo Steels” in which the formula is limited to the tensile elastic limit and reduction of area.

In the mills, molybdenum steel has been found to work satisfactorily, being relatively as free from seams and similar defects as the older types of alloy steels; it is also freer from thick and tenacious scale than are the nickel and chrome-nickel types. It seems to flow readily, particularly in drop forgings, and can be worked over quite a wide range of temperature, say, from 2100° to 2500° F. (1150 to 1370° C.), though the higher temperature would not be recommended for steel containing above 0.25 to 0.30 percent, carbon.

The steel seems to have a wide safe heat-treatment range, as measured by static tests. But it is not advisable to stress this point as it leads to carelessness in heat treatment. In addition, it has been found that static tests are somewhat misleading in this regard. While many steels of high quality can be forged or heat treated through a considerable range of temperature without apparent loss in static qualities, dynamic or shock tests seem to indicate that for every steel there is a temperature at which the maximum of static and dynamic qualities are obtained. Shock-test methods in this regard are of especial value in supplementing our knowledge of materials or even in detecting faulty heat treatments that static tests do not show. Molybdenum steels seem to machine more readily at a given Brinell hardness than do other steels. This would mean, of course, that parts that must be heat treated and machined afterwards could be utilized in a state showing higher physical properties than have been customarily obtainable. The physical property on which molybdenum seems to exert most effect is the reduction of area, which is usually considered a good measure of toughness.

Molybdenum, particularly in conjunction with chromium, seems to confer the property of deep hardening. This is to be expected from the observation that molybdenum steels resist the drawing temperature to quite an unusual degree. In other words, they require a higher drawing temperature to reduce the physical properties by the same amount that they would be reduced in similar steels without the presence of molybdenum. This indicates that molybdenum tends to keep the carbon in steel in the combined or martensitic form, and when in that condition to retard its passage to the sorbitic or troostitic state. Some years ago the writer sent to Prof. H. C. H. Carpenter, then at the National Physical Laboratory of Great Britain, a chrome-molybdenum steel together with a variety of commercial high-speed steels for use in his investigations upon the drawing or softening of hardened high-speed steels. This particular steel contained but 4 per cent, of molybdenum, 3 per cent, of chromium, and about 0.47 per cent, carbon, yet it resisted the drawback temperature, as measured by Professor Carpenter’s etching method, to a greater extent than any of the commercial tungsten high-speed steels used by him, whether of American or British manufacture.

It is possibly too early to make predictions, but the writer believes that molybdenum has established for itself a permanent place among the alloy steels found useful to the airplane, automobile and general engineering trades. It will not wholly displace any other type of steel, but the effect of improvements of this kind and new products has been rather to extend the field of usefulness than to eliminate products of previously demonstrated merit. The Bessemer and open-hearth processes, and the electric furnace have not displaced the original crucible cast steel business. The demand for steels made by each method has arisen with the process itself.

Not only does molybdenum below 1 per cent, give no trouble from volatilization, but it may be recovered from scrap when remelted in the open-hearth furnace to a large extent.

Interesting facts about molybdenum

In his discussion of the characteristics of molybdenum structural steels, Doctor Mathews has covered all the outstanding qualities of these steels that have come under the observation of the writer, except perhaps the fact that such impact tests as have been made have been favorable. Doctor Mathews believes that these steels will not entirely replace any of the older alloy steels but that they will supplement and enlarge the sphere of usefulness of alloy steels in general. An illustration is the apparently marked adaptability of some molybdenum steels for sheet-metal parts, such as automobile frames, axle housings, rims, etc., a field in which the other alloy steels have not played a prominent part.

In this connection, the thought presents itself that perhaps the movement toward standardization of steel specifications should be carried a step farther and a single type of alloy steel be agreed upon as standard. Of course, such a standard would apply only for general purposes; there are many special cases where the fitness of a particular type of steel is unquestioned. Widely differing types of steel are now being used to meet almost identical conditions and the preference of steel users for this or that type of alloy steel often is not based on fundamentals. The writer does not think that the time is ripe for such a move but offers this idea as a possible development of the future.

A large maker of molybdenum steels said that he could put molybdenum into steel with less loss by using a molybdate salt than by using ferro-molybdenum. When we consider that in making ferro-molybdenum there is considerable loss in the electric furnace in which the ferro-molybdenum is made, the total loss of molybdenum should be much less when the oxidized compound is used directly, if it is efficiently reduced by the steel.

From the steel makers’ point of view, as Doctor Mathews points out, the structural molybdenum steels are most desirable to manufacture, no unusual difficulties presenting themselves from the melting to the finished bar. The final yield is as great, even greater, than in the case of carbon steels; furthermore, there is no loss of molybdenum in the remelting of the scrap. The forging is attended with no exceptional features and the machining properties are excellent. The heat treatment is accomplished with greater ease, due to the wide range of temperature to which these steels may be heated before quenching, without deleteriously affecting the physical properties; and the effect of a greater variation in the drawing back, or annealing, temperature is less marked on the physical characteristics. As rolled by the producing mills, the tensile- test values are higher and more uniform even than carbon steels.

The Government tests of armor plate have shown that for resistance to the passage of the projectile, these chrome-molybdenum steels surpass chrome-nickel and other alloy steels. The tensile-test values from the transverse and longitudinal specimens are so nearly the same that the most satisfactory guns and other armament equipment requiring such similar characteristics have been made of these steels. Observation has shown that where the tensile-test values in the longitudinal and transverse test specimens are close to each other, the resistance to shock is usually good.

Automobile springs of chrome-molybdenum steels have demonstrated their superiority to the other alloy steels, not only in the static and laboratory tests, but also in service. Gears, connecting-rods, and crankshafts have proved most efficient when made from steel containing, in addition to molybdenum, either chrome or nickel, or both, though the chrome-molybdenum combination offers the greater ease of manufacture.

Effect of molybdenum in stainless steel

Doctor Mathews, referring to the effect of molybdenum, states that a tendency is indicated to keep the carbon in the combined or martensitic form, and when the carbon is in that condition, molybdenum retards its passage to the sorbitic or troostitic state. Whether this is the case, or whether the molybdenum retards the formation of ferrite or pearlite, preserving a martensitic orsorbitic state through a longer range of annealing temperature, is of no consequence, except from a scientific point of view. The result of the addition of molybdenum is a product that offers a solution to some of the difficult problems now confronting the users of steel.

The railroads with their heavy locomotives and larger freight cars have about reached the practical limit of section and carbon content in the steel rail; in fact, it would seem that these limits have been exceeded, if my deductions made from the reports of various investigators are correct. The heavy rail sections are almost impossible to roll and finish at the uniform low temperature required to give a homogeneous fine grain structure with the high carbon steel necessarily used to give the required carrying capacity and wearing properties. Under service conditions, such rails develop interior defects that become fissures and eventually cause sudden breakage. Molybdenum, particularly in the presence of chromium, tends to give a product with a higher elastic limit. A lower carbon may, therefore, be employed, which would give a fine homogeneous uniform grain structure with the high finishing temperatures necessary to the manufacture of rails of large section. The following tensile-test values are of interest in this connection:

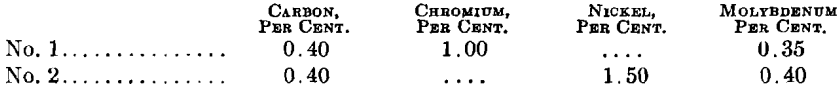

Molybdenum steel composition

Rails, therefore, of the carbon content in vogue when 80 lb. was a large section (0.50 to 0.60 per cent.) with 0.50 per cent, chromium and 0.25 per cent, molybdenum could be readily rolled and finished at the necessarily high temperature required for the 130-lb. section, producing a uniform fine grain and with an elastic limit in excess of the 0.80 per cent, carbon steel now in use. There would also be a corresponding increase of hardness. Such rails would have higher carrying capacity and offer less chance for the development of interior defects under service conditions and greater resistance to wear. Such rails would be tougher and, before failure, would give previous surface indications. The first cost of rails of this composition would be higher than those made of straight carbon steel, but the results obtained from the chrome- molybdenum steel rails would make them even cheaper in the long run, not to mention the security obtained through their use.

The tensile-test value of ferrite and pearlite is low compared to that of semi-martensite or sorbite, the characteristic not only of molybdenum steels, but also of the tungsten and some of the higher chrome-nickel steels. Nickel and chrome-nickel steels have been used for rails, but the service tests were a disappointment for the reason that nickel, while it toughens, does not harden and it is necessary to keep the carbon content that of the normal straight carbon rail. The manufacturing difficulties, in addition, were such that sound rails were not always produced and the proposition, therefore, was not safe. This is but one case where molybdenum will extend the field of alloy steels.

Chrome-molybdenum steels are no more difficult to manufacture than low straight carbon steels, as has already been pointed out by Doctor Mathews and others.

On account of the greater tensile-test values obtainable from the chrome-molybdenum steels, as rolled, this material would seem to be especially suited to a certain type of bridges, notably the suspension of long span, whether constructed of eyebars or of cables. In such, weight is an important factor and the loading to a degree of approaching elastic limit is permissible. J. A. L. Waddell states “An ideal structural material is an alloy steel to which the name chromol steel has been given, having the following composition: 0.25 per cent, carbon, 0.75 per cent, manganese, 0.75 per cent, chrome, and 0.75 per cent, molybdenum.”

The addition of molybdenum to cast iron apparently increases the tensile-test values and resistance to shock, and at the same time it improves the machining qualities. In cast iron made with steel scrap addition, exceptional improvement is noted. Malleable castings thus made are exceptionally strong and tough.