For most rock engineering projects, it is required to characterise not only the intact rock, but also the rock mass as a whole, and this in terms of strength and deformability. Indeed we said, in a previous topic, that the presence of discontinuities tend to confer to the rock mass lower strengths and higher deformability. However you can imagine that it’s very difficult – virtually impossible to test the whole rock mass like we do for intact rock specimens in the lab. One option is to use classification systems that we can later use to get a correlation to strengths and deformability parameters of the rock mass. The three most common classification systems are the Rock Mass Rating System by Bieniawski, the Quality System by Barton and the Geological Strengths Index by Hook. Due to a matter of time, only the Rock Mass Rating System will be presented, nut the three systems rely on quite similar principles

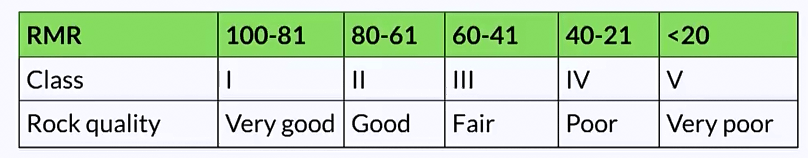

The Rock Mass System, referred to as RMR, provided an overall rating of the rock mass, ranging from less than 20, for very poor rock, to 100 for very good rock. Every rating is associated with a class of rock – class I for a very good rock, and class V for a very poor rock. The overall rating is obtained by adding up the scored pertaining to 6 different criteria. These are the strengths of rock, the rock quality designation, or RQD, the spacing of discontinuities, the condition of discontinuities, the ground water condition, orientation of discontinuities. These will be detailed in the following.

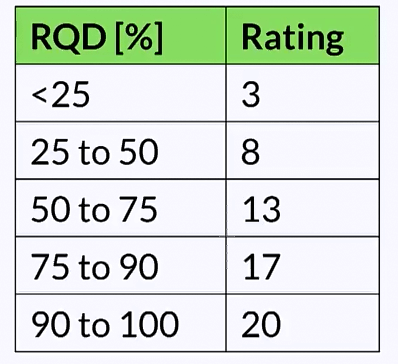

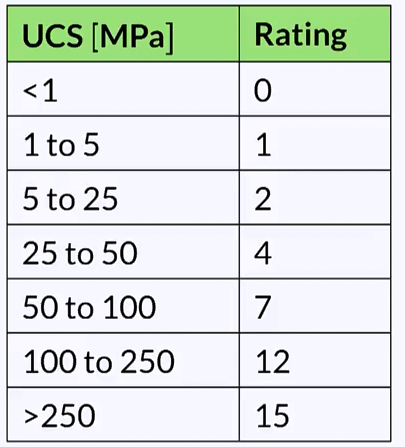

The rating for the rock strength depends on the unconfined compressive strengths of the rock as per this table. I remind you that the way to attend the UCS, or confined compressive strength was covered in topic four. The maximum rating here is 15 for rocks having a UCS in excess of 250 MPA and for rocks having an unconfined compressive strength below 1 megapascal, MPa the rating is 0.  The RMR also accounts for the rock quality designation, which reflects the condition of the rock specimens retrieved from the side. Indeed, very often, cores are broken in pieces of various lengths as per this photo. RQD is defined as the total length of core pieces having a length greater than $0.10 divided by the overall length of the core and it is expressed in percent. The RQD is then correlated to a rating as per this table. The maximum rating is 20, for an RQD of 90% to 100% and the lower rating is 3, for an RQD below 25%. The stronger the rock mass, the less broken the cores and this is why RQD is relevant to the classification of the rock mass.

The RMR also accounts for the rock quality designation, which reflects the condition of the rock specimens retrieved from the side. Indeed, very often, cores are broken in pieces of various lengths as per this photo. RQD is defined as the total length of core pieces having a length greater than $0.10 divided by the overall length of the core and it is expressed in percent. The RQD is then correlated to a rating as per this table. The maximum rating is 20, for an RQD of 90% to 100% and the lower rating is 3, for an RQD below 25%. The stronger the rock mass, the less broken the cores and this is why RQD is relevant to the classification of the rock mass.

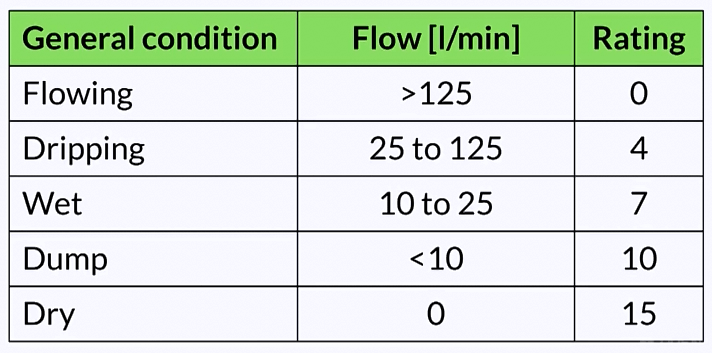

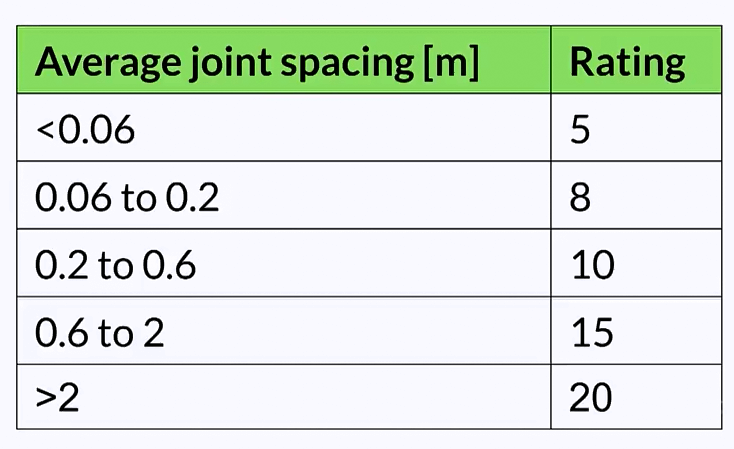

The third criterion is the spacing of discontinuities and the rating is correlated to the average spacing of joints as per this table. The rating starts at 5, for spacing lower than 6cms, and it goes up to 20 if more than 2cms separate to discontinuities. Force criterion is the condition of the discontinuities. In particular, considerations must be given to continuity, filling, aperture, rock wall strength via weathering and roughness. All these parameters were covered in previous topics. Each set of conditions is associated to a rating.  An open, weathered, and continuous discontinuity gets the lowest rating, that is, 0, whereas a dry, rough, closed and weathered discontinuity gets the highest rating, 30. The RMR also accounts for the presence of water is discontinuities, as this, later, is detrimental to stability. The assessment can be done qualitatively, from dry to flowing, or by actually measuring the flow rate. The maximum rating, in absence of water is 15.Finally, the orientation of discontinuities, as its importance for a given project. This will be highlighted in a later topic.

An open, weathered, and continuous discontinuity gets the lowest rating, that is, 0, whereas a dry, rough, closed and weathered discontinuity gets the highest rating, 30. The RMR also accounts for the presence of water is discontinuities, as this, later, is detrimental to stability. The assessment can be done qualitatively, from dry to flowing, or by actually measuring the flow rate. The maximum rating, in absence of water is 15.Finally, the orientation of discontinuities, as its importance for a given project. This will be highlighted in a later topic.

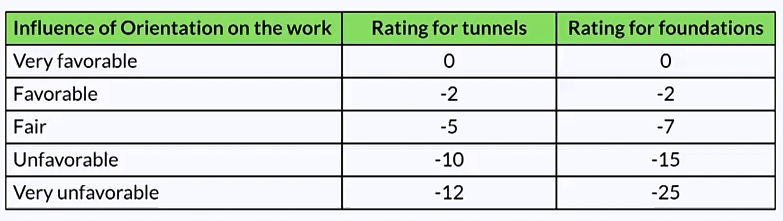

When it comes to RMR rating this table is use. The orientation ranges from very favourable, in which case the RMR rating is not reduced, to very unfavourable, in which case the rating can be reduced by 12 or 25 points. At the end, the RMR rating is obtained by adding the six scores pertaining to the 6 criteria we’ve just described. Well, now what can engineers do with RMR rating? Empirical correlations have being established between RMR rating and rock mass properties, such as strength and deformability. Also, there’s a correlation existing between RMR rating and the design of support for excavations. This is why it is important for engineers to classify the rock mass by using either the RMR or the equivalent systems.

https://youtu.be/uFjRdjZ9yHo