The Reichert cone concentrator is based on the pinched sluice concept. If a number of pinched sluices are arranged side by side, with the discharge ends pointed inward, they will form a circular tank with each sluice forming an individual compartment. Removing the sides of each sluice forms a circular tank with an inverted cone for the bottom, a basic Reichert cone. This design eliminates sidewall interference during mineral separation.

The Reichert cone concentrator is an Australian innovation developed by Mineral Deposits LTD., of Southport, Queensland, Australia. A single unit is formed from several cone sections stacked vertically to permit multiple stages of upgrading. The cones are made of fiberglass, covered with rubber, and mounted in circular self-supporting frames over 20 feet high. These weigh only 2-½ tons for a 75-ton-per-hour feed capacity. Reichert cones accept feed with a density of between 55-70% solids by weight. The unit is very efficient at recovering fine particle sizes and effectively concentrates material from 30 to 325 mesh (roughly 0.5mm to 45 microns). In a test at the Colorado School of Mines Research Institute (CSMRI), a measured sample processed in a Reichert cone yielded a concentrate which contained 95% of the gold (free gold and sulphides) that represented 28% of the original feed weight. Other tests found recoveries of free gold in excess of 90% and consistent recovery of gold smaller than 325 mesh (45 microns) (Spiller, 1983).

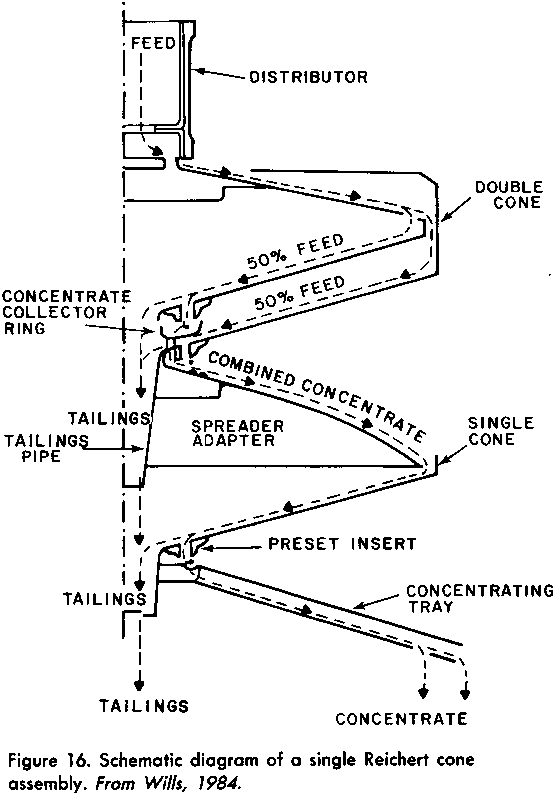

In operation, the feed pulp is distributed evenly around the periphery of the cone. The flowing feed material acts as a dense medium that hinders the settling of lighter particles. Heavy material settles to the bottom of the flow. The concentrate is removed from the pulp stream by an annular slot in the cone (Figure 16). The efficiency of one separation is relatively low and is repeated a number of times within a single unit. Feed fluctuation must be controlled to within fairly close tolerances, and the proportion of clay sizes to feed should be below 5% for maximum recovery.

Concentrates for Reichert cones are usually cleaned in spiral separators or shaking tables although some operators use cones for all phases of concentration. Reichert cones have no moving parts and very low operating costs. They have a long equipment life with low maintenance. Another advantage is that they use less water than conventional jigs and sluices. The success of cone circuits in Australia has led to their application for concentration of tin, gold, tungsten, and magnetite. In many applications, cones are replacing spirals and shaking tables.

Reichert cones are very effective, high-capacity gravity-separation devices. They are lightweight and compact, and have a low cost per ton of processed material. They are suitable for use as roughers, cleaners, or scavengers. Disadvantages include a high sensitivity to variations in pulp density and unsuitability for operations with feed rates of less than 50 tons per hour. This unit should be considered where large volumes of fine gold or other fine minerals are to be recovered and where limited wash water or plant space is a factor.

A Reichert Cone unit normally consists of a series of distributing cone pairs, as illustrated in Figure 3 below. Heavy minerals are removed through circular slots in each cone, which can be adjusted to control the yield. Due to the relative inefficiency of separation, several stages of cones connected in series are usually required for each Reichert unit to achieve adequate metallurgical results. Upgrading Ratios are typically in the range of 3 to 1, which usually leads to further concentrate cleaning by either/or spirals and shaking tables or intensive cyanidation. Feed solids content to a Reichert Cone reportedly should be maintained between 60% and 63% solids by weight, and should controlled to ensure optimum grade and recovery.