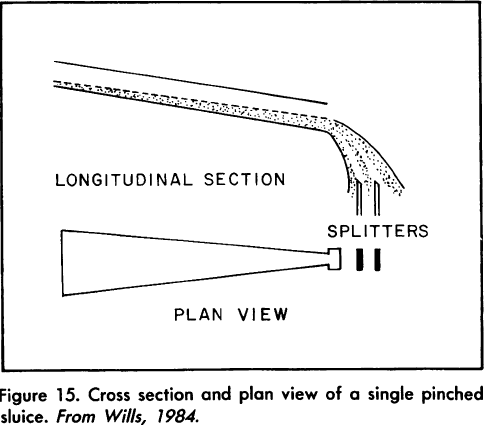

Pinched sluices have been used for heavy-mineral separations for centuries. In its elementary form, the pinched sluice is an inclined trough 2 to 3 feet long, narrowing from about 9 inches in width at the feed end to 1 inch at discharge. Feed consisting of 50-65% solids enters gently and stratifies as the particles flow through the sluice and crowd into the narrow discharge area. Heavy minerals migrate to the bottom, while lighter particles are forced to the top. This separation is inhibited at the walls of the sluice due to drag force. The resulting mineral bands are separated by splitters at the discharge end (Figure 15).

Pinched sluices are very simple devices. They are inexpensive to buy and run, and require little space. Pinched sluices and local variants are mainly used for separation of heavy-mineral sands in Florida and Australia. Models that treat ore material are also used. Recovery difficulties result from fluctuations in feed density or feed grade. A large number of pinched sluices are required for a high capacity operation, and a large amount of recirculation pumping is required for proper feed delivery. These drawbacks led to the development of the Reichert cone.