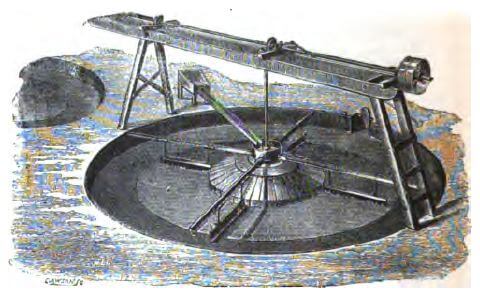

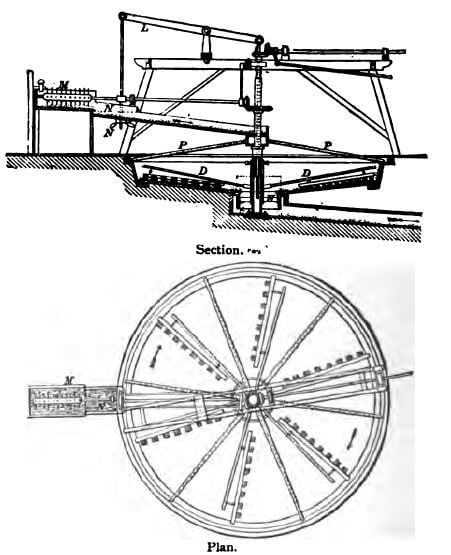

The Round Buddle was invented in Cornwall, where it is still used in dressing the tin ores to the exclusion of almost every other concentrator. There are two varieties.

The Round Buddle was invented in Cornwall, where it is still used in dressing the tin ores to the exclusion of almost every other concentrator. There are two varieties.

- The convex round buddle, in which the ore and water are added at the centre of the machine, and flow down over the surface to the periphery.

- The concave buddle, in which the pulp is added at the periphery of the machine and flows down to the centre.

In both cases revolving arms, carrying brushes, pass over the surface and stir the deposit as it is being formed, and the spouts disturbing the ore also rotate so as to deliver the pulp evenly. The buddies are from 12 to 18 feet in diameter.

These machines are not continuous in action, and after the deposit has accumulated to a depth of a few inches the operation is suspended and the deposit dug out. The “headings” or material on the upper 12 to 18 inches of the inclined surface are kept separate, and the stuff near the bottom of the slope is called the “tailings.” Round buddies are not adapted to obtain a finished product in one operation. The headings and tailings must, as a rule, be subjected to further treatment, and between them is a large quantity of material which differs little from the original ore. Thus handling and re-handling of the stuff is necessitated, and it is on this account that these machines are not now much used on gold ores. The principle on which they depend is favourable to the collection of slimes, and the modern improved buddies are perhaps better adapted for fine ores than any other machines, except those employing a travelling belt. Modifications have been proposed to adapt these buddies to the treatment of gold ores by adding riffles containing mercury, and by other devices, but have not found much favour. One of the chief changes, which was proposed in the United States, is to keep the brushes and ore-spouts stationary, and to rotate the inclined bed.

Among concentrators with circular revolving beds, which were apparently suggested by the revolving buddle, may be mentioned Hendy’s and Duncan’s machines. These were formerly employed in California, but have given place to the vanners which are better adapted for saving slimes.

German buddle

One of the oldest and most primitive machines employed in the concentration of fine sand by means of a shallow stream of water was the German buddle, which has a distinct but imperfect resemblance to the Long-Tom. Canvas tables were used below these buddies in Germany, and probably suggested the use of blanket-strakes or tables, which were adopted in the early days of the goldfields of the United States and Australia, and are still retained in some places. The rough surface of the blanketing seems to be particularly efficacious in catching and holding thin plates and spangles of free gold or of sulphides, which are readily washed off smooth surfaces by a current of water, and these rough appliances, although almost useless for catching slimes, still find favour where considerations of economy prevent the purchase of modern high-priced concentrators. The blanketing is usually in strips of 16 or 18 inches wide, and several feet long, and is nailed or stretched on wooden frames, which have an inclination of about ½ inch per foot.

At intervals of about half an hour, when a quantity of mineral has already been collected on the rough surface, the blankets are taken off and washed in tubs of water, where a deposit collects which is afterwards dug out. At the St. John del Rey Mine, the framework supporting the blankets was hung on pivots above a shallow tank. When it was necessary to clean them, the framework was turned so that the upper surface of the blanket was inclined downwards, and the mineral washed off its surface by a hose, much time and labour being thus saved.

At this mine the trays supporting the blankets were 18 inches wide and 30 feet long, with a fall of 1 inch per foot. The upper 16 feet were covered with bullocks’ skins, tanned with the hair on them, and in lengths of 26 inches; below these were a series of blankets or baize cloths of the same length, made of coarse wool with a long nap. The fall from the battery box upon the tray was 4 inches, a screen being placed across the end to break the fall of the water, and cause it to strike the tray nearly at right angles. About 90 per cent, of the gold contained in the ore was caught on these blankets. The blanket sands contained 95 per cent, of sulphides, and were so fine that 90 per cent, of them passed through a 100-mesh sieve. They were amalgamated in revolving wooden barrels, yielding 96 per cent, of their assay value, but this was due to the fact that very little gold was contained in the pyrites, most of it being present in the form of free particles.

Blanket sluices have been declared unsuitable for catching fine sulphides, and their concentrates are usually contaminated by admixture with much sand. If set at a proper inclination they will save fine amalgam and free gold, but even in this respect they are less satisfactory than shaking copper plates and riffles.

Riffled sluices were employed at the same time as blankets for effecting rough concentration. The riffles were formed of half¬inch strips of wood nailed across the sluice box, the grade of which was about three-quarters of an inch to the foot. As soon as the concentrates had accumulated until they reached the top of the riffle, another strip was nailed on, and the process was repeated until the bed of concentrates was several inches thick, when they were scraped out and a fresh start made.

Similar to this device was the raising-gate concentrator, which was practically a riffled sluice in which the riffle was raised continuously by machinery, instead of being adjusted at intervals by hand.