There are two classes of rock breakers machines in general use:

- Jaw crushers with reciprocating motion, and

- gyratory crushers

The Blake and the Dodge crushers are representative of the former class, and the Gates and Comet crushers of the latter. The Blake Crusher is shown in section in Fig. 22. The rock is crushed between the stationary jaw, B C¹, and the swinging jaw, D, which is pivoted at E, and moved by the eccentric, F, through the toggles, J K. The jaw plates, C¹C³, usually consist of chilled cast iron with longitudinal corrugations. The machine works at about 250 or 300 revolutions per minute. At each revolution the moving jaw is advanced about ½ inch towards the other, and the lumps of rock which have dropped down between the jaws are broken; as the moving jaw recedes, the fragments slip lower down and are further crushed at the next advance, and this process is repeated until the ore is small enough to pass out at the opening at the bottom. The distance between the jaws at the bottom limits the size of the fragments, and this distance may be regulated at will by moving the wedge, L, or by changing the length of the toggles, J K. The capacity of the machine is great, being about 300 tons of ordinary rock per day of twenty-four hours in the case of the machine whose dimensions at the mouth are 20 inches by 10 inches, when the lower edge of the jaws are set to approach within 1½ inches of each other. The power required for this is stated to be 14 H.P.

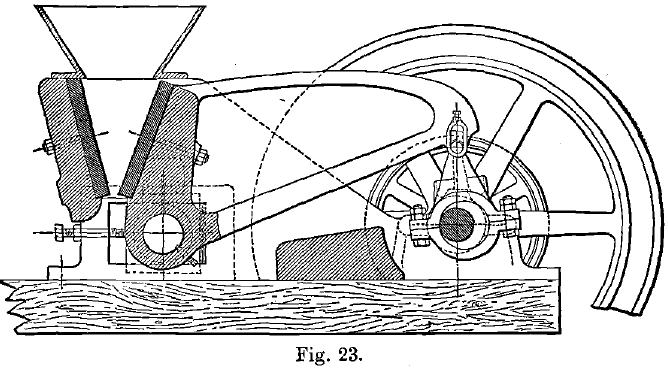

In the Dodge Crusher, shown in Fig. 23, the moving jaw is pivoted below instead of above. The effect of this arrangement is to make the product more uniform in size, and as there is little or no motion of the movable jaw at the delivery aperture, this may be made as narrow as desired, so that a finer product can be obtained, although it is at the expense of capacity. The Dodge crusher is more particularly recommended for fine crushing in concentration works, or where the product is to be subsequently passed through rolls.

Authorities differ as to the relative advantages of the two positions of the pivot. R. H. Richards decides in favour of placing the pivot above, assigning as a reason that the work of crushing is in that case more evenly distributed, whereas if the pivot is below, most of the power is used near the throat or discharge aperture.

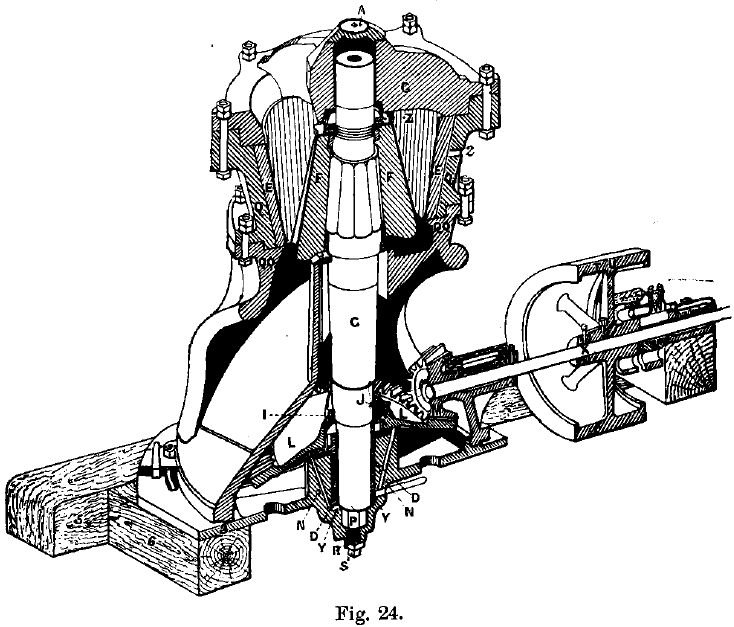

The Gates Crusher is shown in Fig. 24, and consists of a vertical spindle of forged steel, G, revolved by the bevel wheel, L, and a bevel pinion. The spindle is set eccentrically in the bevel wheel, and has a gyratory motion when rock is being crushed. At the top of the shaft is a chilled-iron breaking head, F, and the shell surrounding this is lined with twelve chilled- iron concave pieces, E. These form the crushing faces.

The Comet Crusher is a similar machine which has come into use more recently. In the later form of this machine, the ” Adjustable Comet” the size of the product can be varied by turning a handwheel.

Gyratory crushers are of far greater capacity than machines with reciprocating motion, and have accordingly come into use where a large output is required. The largest size Comet crusher is said to have a capacity of from 100 to 200 tons of rock per hour.

Position and Use of Rock-Breakers

The aperture of a rock- breaker is placed on a level with the floor, so that the ore can be dumped down by the side and shovelled into the jaws. It is now becoming customary to place the rock-breaker in a separate building distinct from the battery house.

A grizzly or screen of steel or iron bars, set 1 or 2 inches apart, is usually employed to separate the fine material, which is passed straight to the stamps.

The efficiency and economy in crushing, attained by rock-breakers, are so fully recognised that efforts have been made to use them to reduce gold-quartz to a very small size before feeding it into the stamp batteries, with a view to increase the output. For fine crushing, multiple-jaw crushers, on the same principle as the Blake, have been constructed, but have not passed into general use ; the use of a pair of rolls between the rock-breaker and the stamp battery has also been advocated.

The usual size, however, to which ore is reduced before it is fed into the stamp mill is 1½ or 2 inches maximum. Any finer preliminary crushing is unusual, and probably uneconomical. At the present day no large mills are erected without rock- breakers, which have also been successfully added to many old mills.