Table of Contents

Each application dictates the selection of proper feeding arrangement. This depends upon whether the grinding will be open circuit or closed circuit, and dry grinding or wet grinding. The size of feed and tonnage rates are also important factors.

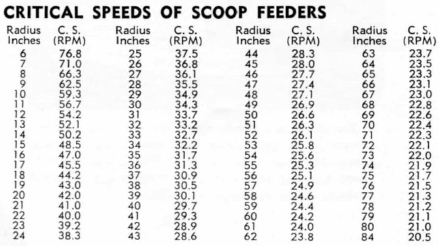

Speed of scoop lip is important. Listed below for your convenience is a table showing critical speeds for various radius scoops. Tip of scoop lip speed should not exceed 90 to 95% of critical speed. Beyond this scoop efficiency decreases and scoop will have the tendency to throw material rather than pick it up.

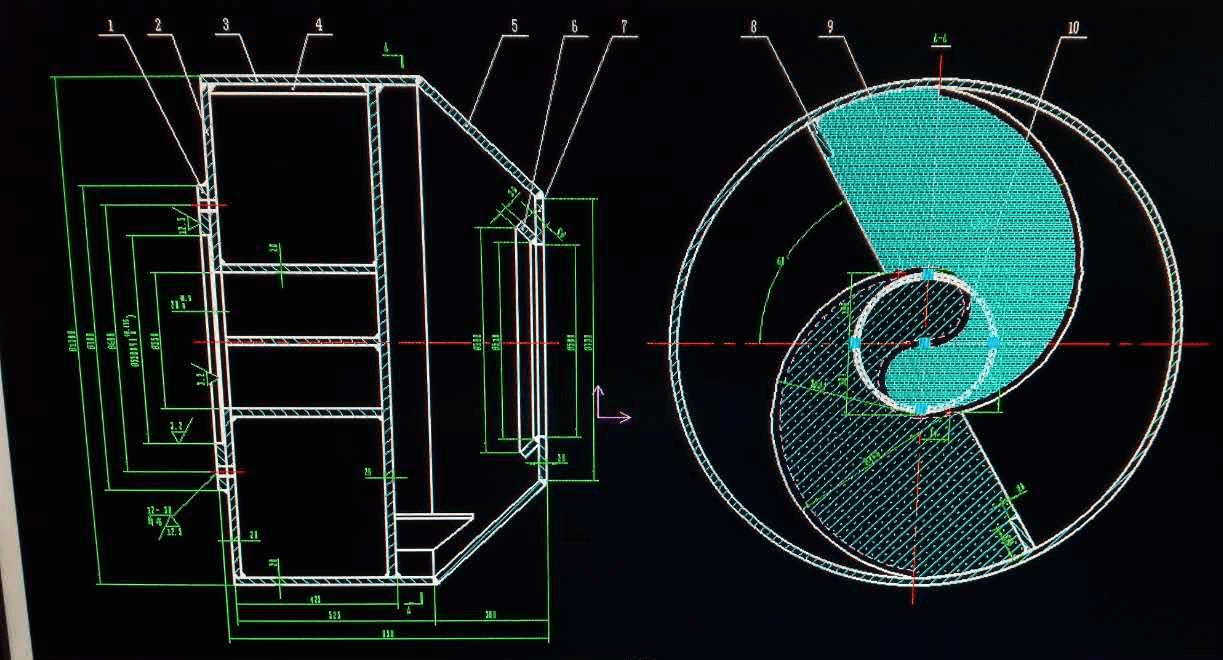

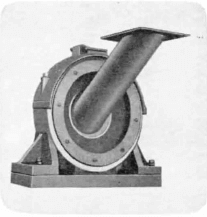

SCOOP FEEDERS

The single scoop feeder provides a simple means of picking up and delivering the entire amount of feed to the grinding mill. These feeders are generally used where the size of feed will be relatively fine. The internal construction of the feeder is such that a spiral carries the feed into the trunnion liner.

The double scoop feeder is furnished of similar construction but has an additional advantage of maintaining a balanced and more uniform feed rate to the mill. This design also provides a counter-balanced rotating mass smoothing out power peaks and permits handling slightly higher tonnages. Each scoop is provided with replaceable Manganese Steel wearing lips.

SPOUT FEEDERS

This is the simplest form of feeder consisting of a cylindrical or elliptical chute supported independent of the mill and projecting directly into the trunnion liner. This permits a continuous flow of material into the mill and reduces maintenance compared to other types. This feeder provides maximum feed capacity to a mill. It is limited to applications where sufficient elevation of feed and any circulating load permits this gravity flow. A special trunnion liner is required.

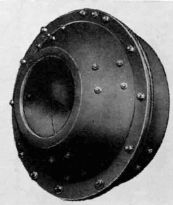

DRUM FEEDERS

This feeder is generally used for single pass grinding work. The entire mill feed enters the drum via a chute or spout and an internal spiral carries the feed into the trunnion liner. The drum feeder may be used in lieu of a spout feeder when headroom limits direct spouting. The drum also provides a convenient method of adding grinding balls to a ball mill. The drum is generally lined with Manganese Steel.

COMBINATION FEEDERS

This is most often used in closed circuit grinding. It is generally split for easy access to the interior and lined with Manganese Steel. Original feed enters the drum and return classifier sands are picked up by the scoop. Either a single or double scoop arrangement can be furnished.