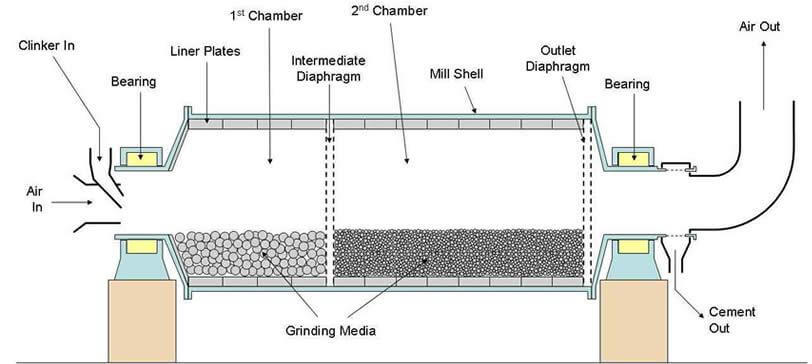

Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater. Usually the shell length is between 2 and 5 times the diameter. These mills are primarily used to grind various materials to 100 mesh and finer. The Tube Mill uses iron or steel balls as the grinding media, and liners of various metals and alloys.

Where iron contamination is detrimental such as in the case of grinding Feldspar for porcelain, Corundum, talc, certain clays, chemicals and glass sand, a pebble mill is indicated. In such cases the mill is then lined with silex, granite blocks or porcelain, held in place by special cements. The general construction of a pebble mill is much lighter since the load is much reduced. The horsepower requirement, size for size, is lower than for a tube mill.

Either type of mill may be operated wet or dry. In wet grinding the tube mill operates in closed circuit with a mechanical classifier. In dry grinding an air separator is used on the finer separations to classify and return the oversize to the mill. A great number of these mills will operate in open circuit on single pass grinding. Feed size is usually limited to -1/8″ in pebble mill grinding and may be increased slightly to about ¼” in tube mill grinding. One of the main applications is in the regrinding of flotation concentrates prior to further treatment.

The use of grates in these long mills for the purpose of increasing the migration of finished product

becoming more and more common. Tests conducted at a Canadian plant have shown 30% to 40% tonnage increase when using grates as compared to an overflow type. Little or no increase in power or pebble consumption was noticed. Tests run by Sylvanite Gold Mines in Canada have shown 13% to 25% more -200 mesh produced on a power basis in a Grate Tube Mill than produced in an overflow tube mill. On the basis of mill volume the grate mill shows 10% to 29% more capacity per cubic foot than overflow tube mills.

These Mills are available with a wide variety of feeders and types of drives. The general construction of these mills is similar to that outlined in the section pertaining to Mill construction. For special applications these mills can be designed for batch grinding work rather than the normal continuous grind.

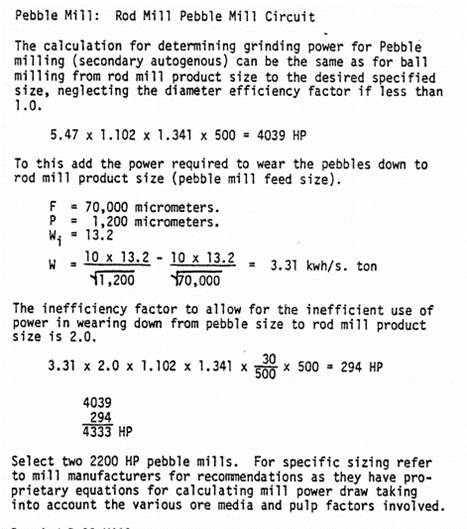

The table below lists a few sizes of Grate Discharge Ball-Tube mills with their typical capacity based on wet grinding 8 mesh feed to 100 mesh in closed circuit with a suitable classifier. For dry grinding reduce capacity approximately 30% to 50%.

Tube Mill Capacity

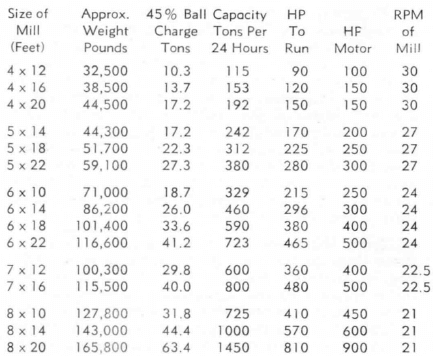

The table below lists a few sizes of Pebble Mills with their typical capacity based on regrinding 8 mesh feed to 100 mesh in closed circuit with a suitable classifier, using pebbles; wet grinding. For dry grind reduce capacity approximately 30% to 50%.

Pebble Mill Capacity

PEBBLE MILL LINERS

The lining for pebble mills may be either standard types of metallic lining, or for the prevention of iron contamination non-metallic materials can be used. Such non-metallic lining material is Jasper, Silex, or other tough, hard natural stone. A recent development is the Coors high-strength Alumina ceramic mill lining brick. This has the following characteristics:

Tensile strength—18,000 to 20,000 PSI

Compressive strength—200,000 to 225,000 PSI

Flexural strength—45,000 to 46,000 PSI

Modulus of elasticity—31.900.000

Hardness, Moh’s Scale—9

Specific Gravity—3.4

It is available in 1½” thick plain brick, 1½” thick with lifter bar integral, and 2″ thick plain.

PEBBLE MILL GRINDING MEDIA

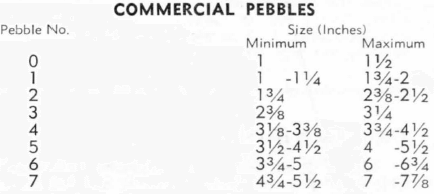

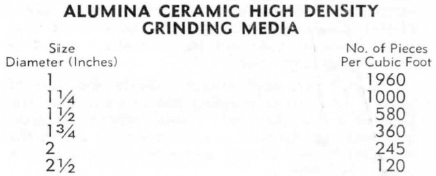

Grinding media may be either pebbles, rock, or the new development known as Coors Alumina Ceramic high density grinding media. The media charged to a pebble mill should be between 50% to 55% of the mill volume. The desirable characteristics of such grinding media are that they should be tough, hard, heavy, and resistant to any chemical action, with the material to be ground. Pebble consumption generally averages 2# per ton with a wide variation of between ½# to 9# per ton. Relatively smooth lining results in less media wear, as does maintaining a high circulating load.

The above media weighs approximately 135# per cubic foot. It is shipped in 100# sacks. It is pre¬ground to remove the slightly rough “as fired” surface.