Small Screw conveyors are used principally for bulk conveying of light and fluffy dry material, materials which dust badly when conveyed, hot materials which cannot be handled on rubber belts, and for conveying of liquid pulps. They may be installed on an angle for lowering or elevating materials. With the bottom or end of trough fitted with a screen cloth, they may be used for dewatering. When operating at slow speeds, they make a good feeder. Troughs are sometimes water jacketed for the purpose of cooling concentrates as they come from the dryer, or steam jacketed for the purpose of drying materials. The use of screw conveyors for handling lumpy and abrasive materials should be avoided as much as possible due to rapid wear of conveyor flights.

A screw conveyor consists of a spiral constructed of steel, cast iron, or special alloys, rotating within a steel, cast iron or wood trough. The trough may be constructed with a dust- tight cover having one or more feed openings, and with one or more discharge openings in the bottom of the trough; the amount of feed and discharge controlled by sliding gates. Types of drives are many: bevel gears, speed reducers, V-belts and roller chain.

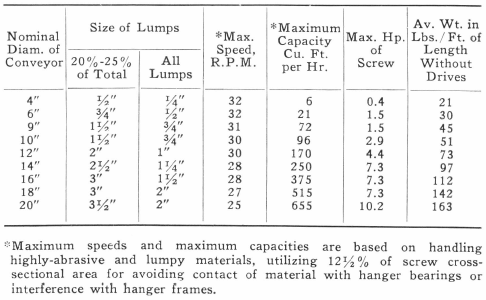

Screw Conveyor Capacity Table