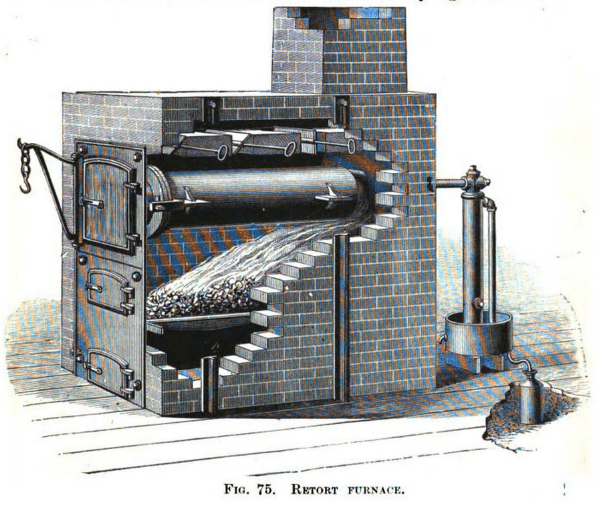

This retort furnace, is an improvement on those formerly constructed. It has three dampers for directing the flames and heat from back to the front end of the retort. As the entire retort and its cover is within the furnace the mercury is equally driven off from all parts of the amalgam, leaving the whole mass equally well retorted.

Formerly the front end of the retort was sometimes left entirely empty, and even then the two first trays were often but half done. A crane on the front plate of the charging door is used for lifting out the cover, which enables the operator to open the retort without waiting for it to cool. Four sizes of the retort are made whose weights are given below ; the smaller numbers are adapted for gold amalgam, where the capacity required exceeds 1500 oz.

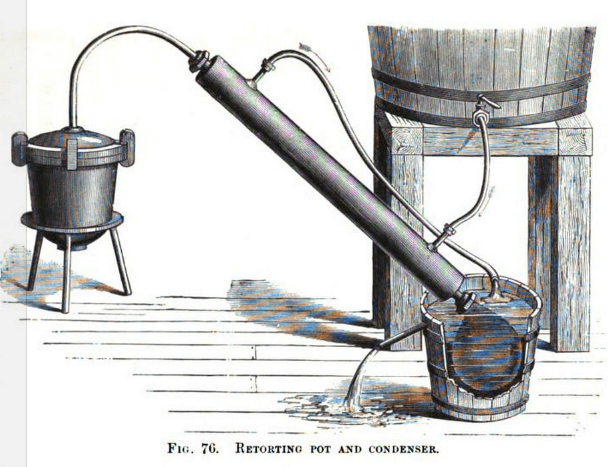

In some small gold mills, where the amount of bullion produced is not large, simple pots or bulb retorts of cast iron arc used in place of the cylindrical ones. The pots or bulb retorts require no brick fitting, and can be used over an assay furnace or a blacksmith’s forge, and are convenient for operations on a small scale.

Both the alembic and cap retorting pots, should always be turned out smooth. Before using them, the inside should lie well rubied with chalk. Coating them with moist ashes is bad for the iron, as the alkali will soon honeycomb it The amalgam balls must be broken up before they are put into the retorting pot, and placed in loosely. The pot must not be more than two-thirds to three-quarters full. Ramming the amalgam hard and solid into the retorting pot, as is sometimes done, is had practice, as it requires longer to distil out the mercury, and rarely leaves the heart of the retort piece thoroughly distilled.

The flange of the retorting pot may be luted with moistened chalk or sifted ashes, which, when dry, can readily to be brushed off. This is applied of the consistency of thick molasses, and the cap slightly turned when put on, to make sure of there being no grit or gravel in the luting. The retort is then keyed up and placed in the furnace, or left on the ground and covered over with fuel. The end of the condensing pipe should never be placed in the water without a cover, as it is apt to result in explosions unless one is an expert at retorting. A canvas or rubber bag should be tied or screwed to its end as shown in Fig. 76 before it is immersed in the water. When the mercury vapour begins to flow over, the bag will .swell up ; this distension is a sign that the mercury continues to come over ; it is continually being condensed, and when the condensation ceases the bag will collapse, indicating the completion of the operation.

The condensing pipe should be kept as cool as possible by a Liebig’s condenser, as shown in Fig. 76, or if that cannot be done by continually pouring cold water over it. These retorting pots are made in seven sizes, to contain at two-thirds full, from 150 oz. to 2000 oz.

Bark makes the best tire for retorting. The tire should be lit at the top and allowed to work down ; when it reaches the grate more bark should be put on and the retort kept covered. It should be kept at a bright red until the bag begins to collapse. The tire is then removed and left until it is burnt out and the retort cooled down to blackness.

After twenty or thirty minutes the bag is taken off, the mercury removed and disposed of. The “ retort” is lifted out but not opened for at least twenty minutes more. When opened it is turned over on a gold pan or other receiver; and, if the retort gold does not readily fall out, a few light taps on the outside will dislodge it.