Table of Contents

Aggregates required for a given job are generally specified by a full set of gradation limits and other relevant properties of the material. When rock is crushed, the product includes material of the size of the crusher setting, some slightly larger and the rest of the material smaller than the crusher setting. Crusher manufacturers publish grid charts, particle size cumulative distribution curves, and/or product size distribution tables to help predict the gradation of the crusher product. These charts, curves, and tables give the percentages passing or retained on standard size screens for each given setting of the crusher.

Screen Analysis of Product from Jaw Crusher, Percent Passing Screen Opening

|

Product Size (in.) |

Closed Side Setting of Crusher (in.) |

Product Size |

|||||||||

|

3/4 |

1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 |

(in.) |

|

|

Over 10 |

Over 10 |

||||||||||

|

-10 +9 |

0 | -10 +9 | |||||||||

|

-9 +8 |

0 | 2 | -9 +8 | ||||||||

|

-8 + 7 |

0 | 7 |

-8 +7 |

||||||||

| -7 +6 | 0 | 8 | 10 |

-7 +6 |

|||||||

|

-6 +5 |

0 | 0 | 5 | 12 | 12 | -6 +5 | |||||

| -5 + 4 | 4 | 11 | 13 | 14 | 14 |

-5 +4 |

|||||

| -4 + 3.5 | 0 | 7 | 7 | 9 | 8 | 8 |

-4 + 3.5 |

||||

|

-3.5 +3 |

0 | 7 | 7 | 10 | 11 | 9 | 8 | -3.5 +3 | |||

|

-3 + 2.5 |

0 | 5 | 12 | 13 | 12 | 10 | 10 | 8 |

-3 +2.5 |

||

| -2.5 +2 | 3 | 15 | 16 | 14 | 13 | 11 | 11 | 8 |

-2.5 +2 |

||

|

-2 +1.5 |

0 | 0 | 17 | 17 | 17 | 16 | 14 | 13 | 7 | 6 |

-2 +1.5 |

|

-1.5 +1 |

2 | 19 | 26 | 20 | 19 | 15 | 11 | 10 | 7 | 6 |

-1.5 +0.75 |

|

-0.75 + 0.5 |

20 | 20 | 13 | 11 | 8 | 6 | 5 | 4 | 4 | 3 |

0.75 +0.5 |

|

-0.5 +0.25 |

40 | 25 | 13 | 11 | 7 | 6 | 4 | 4 | 4 | 3 |

-0.5 +0.25 |

|

Under 0.25 |

20 | 16 | 12 | 8 | 7 | 6 | 7 | 6 | 3 | 3 |

Under 0.25 |

|

Setting |

0.75″ | 1″ | 1.5″ | 2″ | 2.5″ | 3″ | 3.5″ | 4″ | 5″ |

6″ |

|

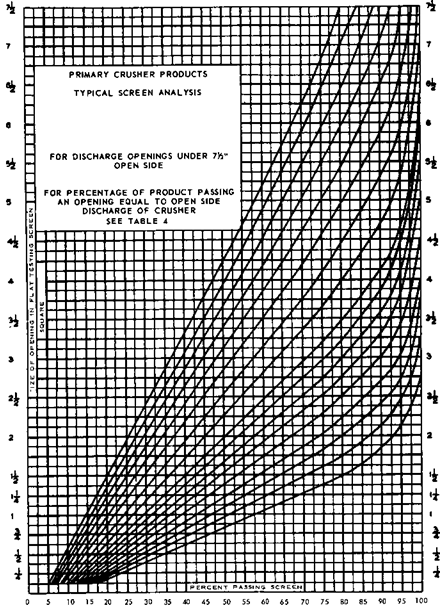

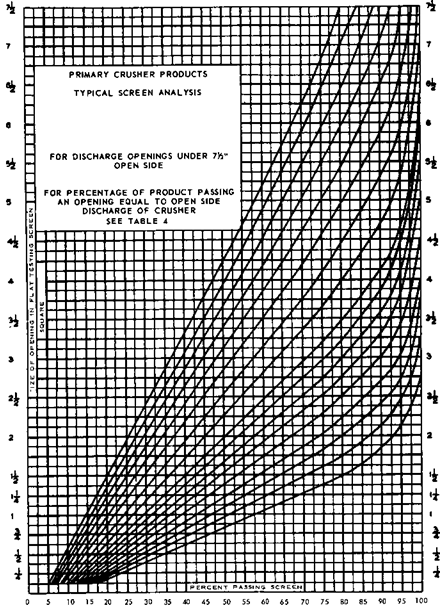

The distribution of product sizes given in the table above is based on crushed limestone weighing 100 lb/cu ft with a specific gravity of 2.6. This same sort of information may be presented by the manufacturer in a set of curves for the various settings of the crusher.  The curves, one for each closed side setting, will give an estimate of the cumulative percentage of material passing a given screen size on the horizontal scale with the screen opening in inches on the vertical scale.

The curves, one for each closed side setting, will give an estimate of the cumulative percentage of material passing a given screen size on the horizontal scale with the screen opening in inches on the vertical scale.

|

Percentage of Product Passing Square Opening Equal to Crusher Open Side Setting |

|||

|

Feed (%) |

|||

|

Type of Crusher |

Run of Quarry |

Scalped Percent |

Scalped and Recombined with Fines |

|

Limestone |

|||

|

Jaw |

90 | 85 | 88 |

|

Gyratory |

90 | 85 | 88 |

|

Granite |

|||

|

Jaw |

75 | 75 | 75 |

|

Gyratory |

82 | 75 | 80 |

|

Trap rock |

|||

|

Jaw |

70 | 70 | 70 |

|

Gyratory |

75 | 70 | 85 |

A jaw crusher, like that of the Table below, is set with an open circuit (no recirculation) at 2 in. to produce 60 tons per hour (tph) of crushed limestone aggregate.

(a) How much of the output will pass a 1½-in. screen (i.e., minus 1½-in. material), and (b) how much of the material—percentage and tonnage—will pass the 1½-in. screen and be retained on the ¾-in. screen?

Screen Analysis of Product from Jaw Crusher, Percent Passing Screen Opening

|

Product Size (in.) |

Closed Side Setting of Crusher (in.) |

Product Size |

|||||||||

|

3/4 |

1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 |

(in.) |

|

|

Over 10 |

Over 10 |

||||||||||

|

-10 +9 |

0 | -10 +9 | |||||||||

|

-9 +8 |

0 | 2 | -9 +8 | ||||||||

|

-8 + 7 |

0 | 7 |

-8 +7 |

||||||||

| -7 +6 | 0 | 8 | 10 |

-7 +6 |

|||||||

|

-6 +5 |

0 | 0 | 5 | 12 | 12 | -6 +5 | |||||

| -5 + 4 | 4 | 11 | 13 | 14 | 14 |

-5 +4 |

|||||

| -4 + 3.5 | 0 | 7 | 7 | 9 | 8 | 8 |

-4 + 3.5 |

||||

|

-3.5 +3 |

0 | 7 | 7 | 10 | 11 | 9 | 8 | -3.5 +3 | |||

|

-3 + 2.5 |

0 | 5 | 12 | 13 | 12 | 10 | 10 | 8 |

-3 +2.5 |

||

| -2.5 +2 | 3 | 15 | 16 | 14 | 13 | 11 | 11 | 8 |

-2.5 +2 |

||

|

-2 +1.5 |

0 | 0 | 17 | 17 | 17 | 16 | 14 | 13 | 7 | 6 |

-2 +1.5 |

|

-1.5 +1 |

2 | 19 | 26 | 20 | 19 | 15 | 11 | 10 | 7 | 6 |

-1.5 +0.75 |

|

-0.75 + 0.5 |

20 | 20 | 13 | 11 | 8 | 6 | 5 | 4 | 4 | 3 |

0.75 +0.5 |

|

-0.5 +0.25 |

40 | 25 | 13 | 11 | 7 | 6 | 4 | 4 | 4 | 3 |

-0.5 +0.25 |

|

Under 0.25 |

20 | 16 | 12 | 8 | 7 | 6 | 7 | 6 | 3 | 3 |

Under 0.25 |

|

Setting |

0.75″ | 1″ | 1.5″ | 2″ | 2.5″ | 3″ | 3.5″ | 4″ | 5″ |

6″ |

|

The solution to each part, using the above table, is:

(a) Following the vertical column for the 2 in. setting shows that 63% of the output passes the 1½ in. screen. So the – 1½ in. material output will be 0.63 x 60 = 37.8 tph.

(b) In the column for a 2 in. setting, it is found that 20% of the output is between 1½ in. and 1 in. size (i.e., -1½ +1 in.) and 13% is between 1 in. and ¾ in. ( – 1 +¾). Therefore, the quantity of output passing the 1½ in. screen and retained on the ¾ in. screen is 33%. The rate of production in the 1½ in. to ¾ in. size range is 0.33 x 60 = 20 tph.