Table of Contents

The gold sluices in which the gold is caught are constructed on exactly the same principles as those already described, but are larger and, though usually made of wood, are of more massive construction, in accordance with the great quantities of gravel to be handled and the continuous nature of the work. The sluices are commonly called “flumes,” but it is better to restrict the use of this word to a conduit for carrying water only. The sluice boxes used in hydraulic mining, though, as usual, only 12 feet long, are as much as from 3 to 6 feet wide and from 2 to 3 feet deep; they are lined with heavy planks on the sides, and the pavements are made of more durable materials than is usual in shallow placer sluicing, wooden blocks, rocks, or T railroad iron being most usually employed. The wooden blocks are from 12 to 30 inches square, and from 8 to 13 inches deep. They are usually made of one of the softer varieties of pine which “ broom up ” under friction, and thus present a better catching surface. The blocks are cut across the grain of the wood, and are set side by side across the sluice, each row separated from the next by strips of wood to which they are nailed, while they are also kept in position by the side lining which is placed upon them. The interstices in the block pavement act as gold catchers, and are filled with small stones, or, with less advantage, allowed to fill up with gravel when washing begins. On account of the rapid wearing away of the wood, much of the gold and amalgam caught is scooped out and carried off again. Wooden block riffles last only a few weeks when in heavy work, but are easy to take up and put down again in cleaning up; they are discarded when worn so as to be only 4 to 6 inches thick.

Rock pavements are made of those boulders which are most easily obtained in the particular district. Basalt is generally used, oval stones of 15 or 18 inches long and from 9 to 12 inches thick being selected and placed on end, with a slight slant in the direction in which the current flows. They are held in place by wooden planks which divide the sluice into compartments, so that if one stone works loose the pavement as a whole is not affected. The interstices as before are filled with gravel. Rock pavements are very durable, lasting from three to six months, but require more grade to the sluice, and occasion loss of time in cleaning-up and repaving the sluices. Consequently, they are never used near the head of a sluice, where cleaning-up is a frequent operation, but are often used for the lower parts of sluices, where they sometimes alternate with block riffles, and are especially suited for tail-sluices which are only cleaned- up once a year. Rock pavements cost less than other forms of riffles.

Iron riffles, which usually consist of T-iron rails, are placed longitudinally in the sluice, closely packed side by side. They present a large amount of space available for catching the gold and amalgam, last well, present little resistance to the current (so that the grade may be low while the duty of the water remains high), and are easily taken up and put down. They are, therefore, generally used at the head of the sluices. Though their first cost is higher than that of wooden blocks, they are more economical in the end, owing to the saving of time in cleaning-up and to their longer life. Egleston instances the results of experiments made at the Morning Star Claim, California, where three sections of sluice, each 95 feet long, were laid at a distance of 300 feet from the face of the bank which was being worked. The first section was as usual laid with wooden blocks, the second with old rails, and the third with rocks. When the clean-up was made the middle section gave 9 ozs. more of gold bullion than both the others combined. If old rails cannot be had, strips of wood bound with iron are used, but are less durable and satisfactory.

At the Blue Spur Consolidated Gold Company’s plant, Gabriel’s Gully, New Zealand, where the sluice is necessarily very short, most of the stones are first separated from the gravel, and the finer material is then passed over a sluice paved with transverse angle-iron riffles, placed with the hollow side facing down stream (Fig 19, in which the arrow shows the direction of the stream); these iron riffles are placed 2 or 3 inches apart. Below the section containing these riffles, there is a false bottom to the sluice, formed by an iron plate perforated with small round holes through which some of the water and the finest particles of the gravel fall on to cocoa-nut fibre matting, laid on the true bottom of the sluice. Here the fine gold is caught, the principle being similar to that used in undercurrents.

The sluice is often divided into two by a median longitudinal partition, so that one side may be at work while the other is being cleaned-up or repaired, both sides being sometimes worked when water is very plentiful. There are usually unpaved rock- cuts above the sluice, leading to it from the places undergoing the process of piping. These rock-cuts are rarely supplied with mercury, and very little gold is usually caught there.

The length of the sluice, if capital is not lacking, depends on the cost of construction and of the maintenance, as compared with the value of the gold saved owing to the increased length of the system. The length may be diminished by a plentiful use of drops, grizzlies and undercurrents, all of which are described above under the head of shallow placer sluicing; they are made of proportionately large size in hydraulic mining. Coarse gold is of course soon caught, but fine gold may successfully evade all the riffles of a long sluice. The Spring Valley Mine had three parallel lines of sluices, each 2½ miles in length, and it was estimated that 95 per cent, of the gold contents of the gravel was caught. This length is unusual, the average not exceeding about 1,000 feet.

Grade of the Sluices

The grade depends on the available fall of the ground and on the character of the material to be washed. The minimum is from 2 to 4 inches per box, such low grades being sometimes enforced by the nature of the ground, sometimes adopted from choice if the gravel is light, the gold fine, and water plentiful. With these low grades, however, disintegration is slow and incomplete; stones, unless they are small, cannot be sluiced large ones block the sluices and must be removed by hand, and the “ duty ” of the water, as regards sand, is greatly decreased. The 6-inch grade is that most generally used, but as much as 12 inches per box, or even more is required when water is scarce or the gravel coarse. Steep grades effect disintegration rapidly, thus shortening the length of the sluice, and enable all but the largest rocks to be sluiced, but less gold is then caught and a more plentiful use of undercurrents is necessary. It is considered necessary to have a sufficient depth of water to cover the largest boulders to be sluiced, but the deeper the water, the more difficult it is to save gold. Where poor or top gravel is being “piped,” it is worked off as rapidly as possible, and with little regard to the percentage of gold saved.

The “ duty ” of the miner’s inch—that is, the quantity of material washed down by an inch of water in twenty-four hours—varies with the grade and other conditions. It varies from about 1 to 5 or more cubic yards of gravel per inch.

Mercury in Hydraulic Mining

Mercury is added daily during the run in gradually lessening quantities, the object being to keep the mercury uncovered and clean at the top of the riffles. The feeding is regulated by the appearance of the amalgam in the sluice, the additions being made in the riffles near the head-box and in the undercurrents. The loss of mercury is usually from 5 to 10 per cent, of the amount used per run. When cemented gravels are being treated, owing to the extra amount of trituration required, the loss may be as high as 30 per cent. These losses are the more serious, for the reason that amalgam is more easily lost than pure mercury, so that a heavy loss of mercury denotes a heavy loss of gold.

Cleaning-Up after Hydraulic Mining

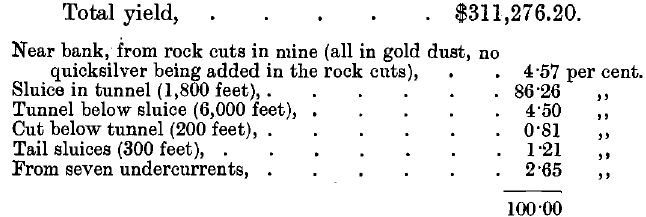

The process does not differ from that described under the heading of shallow placer mining. It is advisable not to defer the clean-up too long as losses of amalgam are caused by the wearing of the riffles. Usually from 50 to 95 per cent, of the total yield of amalgam is caught in the first twenty or thirty boxes, which are cleaned-up frequently. The following table shows the percentage yield of the various sections of the sluices, at the North Bloomfield Mine, California, for the year 1877-8:—

The first undercurrent caught five times as much as the sixth, and nearly three times as much as the seventh, which was of double size. The yield of the seventh ($947) induced the Company to add another undercurrent. This mine affords an example of the difficulty of catching fine gold. The gold loss was unknown, but was believed not to exceed 5 per cent, of the contents of the gravel.

The bullion obtained by retorting the amalgam from the sluices is finer than that from quartz mills, and is sometimes 990 fine in Australia, although Californian placer gold is often as low as 850 fine. The remainder is mainly silver, but copper, lead, iron, and some of the minerals existing in the gravel also occur. The amalgam from the head of the sluices yields finer gold than that caught lower down and in the undercurrents.

Hydraulic Mining Tailings

The tail-sluices usually terminate on the side of a canon, in a river, or in the sea. The enormous amount of loose sand and gravel, delivered from the hydraulic mines of Placer County, California, and the neighbouring counties into the Yuba and Feather rivers prior to 1880, filled up their beds to such an extent that in rainy weather disastrous floods ensued, and much valuable agricultural land was buried beneath sterile drift deposits and rendered worthless. The farmers thereupon took action against the Mining Companies and obtained a perpetual injunction forbidding them to discharge their tailings into these rivers. The result has been to stop hydraulic mining in these districts, and the efforts to work the deep leads more extensively by drifting, or on the other hand, to impound the tailings by dams made of brushwood, or to return them to their original position, have not resulted in unqualified success. Consequently the gold winning industry has not been maintained on the extensive scale it had assumed prior to the action of the courts, the impounding of tailings behind brushwood dams having only partially solved the difficulty.

Extraction Gold from Cement Gravel

In many cases the gravel from deep leads won by drift or shaft mining is cemented by iron oxides or clay into a conglomerate which is too tough to be easily disintegrated in the sluices. It is then passed through “cement mills,” which closely resemble the stamp battery to be described in the next chapter, the chief differences to be noted being in the facilities for delivery. Double discharge mortars are used, and the screens are very coarse, the mesh being usually about inch, but varying up to ½ inch in diameter. One battery of ten stamps, each weighing 950 lbs., making 94 drops of 9 inches in height per minute, will crush about 40 or 50 tons of gravel in ten hours so that it will pass through a 3/16-inch mesh screen. Mercury is put into the mortar, and most of the gold is usually caught there on amalgamated copper plates, but copper plates outside the mortar are also used as in quartz-milling, and rubbers are employed to brighten the gold. If well-arranged plates are laid down, the number of sluice boxes which can be added with advantage is very small, a length of from 50 to 300 feet being used, the former limit being most common. No attempt is made to save the auriferous magnetic sands and sulphides which these conglomerates usually contain.

In the case of the Morning Star Cement Gravel Mine, Placer County, California, quoted by R. H. Richards, the weight of the stamps was 850 lbs., the height of drop 6 to 8 inches,, the number of drops per minute 95 to 100, the size of screen holes 3/16 inch (round), and the capacity per stamp per twenty- four hours 12 tons.

In cases where cement mills are not required, the gravel is washed in sluices which differ little from those already described. The boxes are not more than from 18 inches to 24 inches wide and deep, and the series is seldom more than 300 or 400 feet long. Iron riffles are most in favour. Where the amount of gravel to be washed is small, or the water is scarce, the gravel is allowed to accumulate for some time and the water stored in a tank or reservoir. It is in some cases a great advantage to keep compacted gravels exposed to the air during a few months before washing them, as they “ slack ” and disintegrate under the influence of the weather, and subsequently are more easily treated, while for a similar reason, tailings are sometimes impounded, and re-washed after some time has elapsed. The disintegration of cemented material, which has been “ slacked ” by exposure to the weather, is usually completed in a cement-pan. This is a cast-iron pan with perforated bottom, and with a gate in the side for the removal of boulders, which are mostly barren and are separated from the auriferous material by this system, instead of being crushed and mixed with it, as is the case when stamp-mills are used. In the pan, four revolving arms, furnished with plough-shares, break up the gravel, which is carried through the apertures in the bottom by a stream of water, and falls into the sluice. A pan of 5 feet in diameter and 2 feet in depth will treat from 40 to 120 tons per day, according to the nature of the gravel.

Related: best sluice box, best metal detector, rock tumbler