In arid districts where water is scarce or expensive and a “dry” plant is proposed for the recovery of placer gold, a small dry washer may be the logical choice for processing samples. A number of small, hand-powered machines are on the market and most work quite well within certain limits common to all dry washers used in gold mining.

First, consider two identical gold particles, one in a dry washer and the other submerged in water. It will be shown that the relative weight of the dry gold particle is substantially less than its wet counterpart. This is illustrated by the following equations in which the specific gravity of gold is 19, the specific gravity of gravel 2.65, and the specific gravity of water is 1:

This shows the gold to be eleven times heavier than gravel when immersed in water, as compared to 7: 1 in air. Simply stated — the relative weight of gold is about 1½ times greater when passing through a wet process than when passing through a dry washer. The lesser ratio in air is not too apparent when processing coarse or “shotty” gold but it no doubt contributes to the

dry washer’s often poor recovery of fine or flaky gold.

To respond to dry washing the material treated must be almost completely dry. In most cases 3 percent moisture is considered a maximum. The gold particles must also be completely liberated and free of cementing material such as caliche. In addition, effective separation is usually dependent on use of a closely-sized feed, sometimes not larger than ¼” screen-size. One might say that the amenability of a dry placer to working by the usual (dry) methods varies in proportion to its suitability to sizing by screening.

Besides the well-known difficulties related to drying placer material prior to dry washing and using small-mesh screens, there are other problems less generally appreciated. Wilson and Fansett in referring to tests made at the University of Arizona sum these up by saying:

“A dry concentrator will not make as high recovery as a wet concentrator. Under favorable conditions, the recovery will be approximately ten to fifteen percent less with a dry machine as compared with a wet machine.”

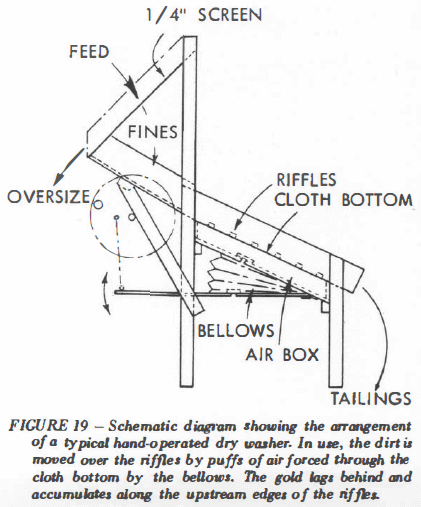

This tells us that in cases where a dry processing plant is proposed for the recovery of gold in a commercial-scale placer operation, it might he advisable to process the initial samples with a small dry washer. Figure 19 illustrates a type of machine found suitable for this purpose. If all else is equal, the recovery obtained from the dry (sample) washer should indicate the recovery to be expected from the full-scale operation. On the other hand, if the samples are washed in a rocker or other wet device, a suitable recovery “correction” factor may have to be applied to the indicated sample values.

DRYWASHER OPERATION

Equipment used for the recovery of placer gold has changed very little over the years and, in general, remains relatively simple. Most devices employ some form of riffled surface to hold the gold or other heavy mineral after it has been separated from the valueless material. The actual separation relies on the ability of heavy minerals to resist the action of moving water while the lighter materials are carried away. In dry washers where a current of air is used as the transporting medium, the same principle applies. Although many have tried, no one to date has devised a gold-saving device or system which can economically replace the ordinary riffled sluices or placer jigs used on today’s dredges or in other comparable large-scale placer operations. It is true that sluices may lose some of the fine gold but his is normally offset by their low operating cost and their high unit capacity which combine to return the greatest dollar profit.

When selecting a machine for washing and concentrating placer samples, the first consideration should be whether or not it will indicate the commercially recoverable gold content of the sample. Other desirable features would be:

- Low first cost.

- Easy to maintain or repair in the field.

- Easy to transport and set up for operation.

- Will accept bank-run material without pre-screening.

- Will thoroughly wash and reject the oversize material.

- Makes efficient use of water.

- Will efficiently process small as well as large samples.

- Will effectively reduce the sample to a small-volume residue or concentrate.

- Can be quickly and completely cleaned between samples.

Is time-tested and accepted by knowledgeable mine operators or engineers familiar with placer sampling requirements.

It should again be stressed that no dredge or other large-scale placer equipment saves 100 percent of the values and because of this it is important that the sample washing process indicate the actual returns to be expected from a commercial operation. In this connection it is noteworthy that the pan, rocker, and the sluice when used by experienced placer operators fulfill this requirement.

Small Mechanical Gold Washers

A variety of small mechanical gold washers have been manufactured and put on the market over the years and although most were intended to be used for small-scale mining operations, some were advertised and sold as prospecting or sampling units. The typical machine consists of a small trommel screen with a feed hopper for shoveling in, a short sluice (which is usually provided with a shaking motion or some kind of “special” riffle), a pump, and a water distribution system, all run by a small gasoline engine. The typical machine weighs more than 500 pounds and requires a pickup truck or a trailer for transportation. Most are no longer manufactured and have passed from the scene but two of the better-known machines are still on the market.

These are manufactured and known as the “Denver Mechanical Gold Pan” and the “Denver Gold Saver” respectively. The mechanical pan has been well received in the industry over a 30-year period and is generally referred to simply as a “Denver Pan.” It comprises an assembly of three shallow, nested pans 2 feet in diameter with two superimposed screens arranged to wash and reject the plus ¼-inch material. The combined assembly is mounted on a horizontally gyrating base driven by a small gasoline engine and the resultant motion is said to duplicate hand panning. The minus ¼-inch material after passing through the screens, progressively flows over the three pans, one discharging into the next. The uppermost pan is provided with an amalgamating plate, and the two successive pans with special rubber mats or cocoa matting held down by coarse wire screen. Capacity of a single unit ranges up to 2 cubic yards per hour and water consumption is said to be as little as 1 to 2 parts (by weight) per part of gravel which would indicate an average of about 1,000 gallons per cubic yard. Single or double units are available and these can be provided with a scrubber and a trommel-type screen. The largest (Duplex) unit when so equipped has a rated capacity of 4 to 6 bank-run yards per hour and weighs 2100 pounds. The single (Simplex) unit without the trommel weighs 675 pounds. The Denver Mechanical Gold Pan is sturdily built and is suitable for continuous use such as would he encountered in a mining operation.

The Denver Equipment Company’s second machine, sold under the name of “Denver Gold Saver”, is well suited for general sampling work in that it can be quickly and easily cleaned thus eliminating the danger of carry-over of values from one sample to the next. It consists of a feed hopper, a combined scrubber and trommel to wash and screen out the plus ¼-inch material, a special vibrating molded rifle, a reserve water storage tank and a centrifugal pump with suitable piping sprays, etc., all powered by a 1½ HP gasoline engine. The complete assembly weighs 750 pounds and has a rated capacity of 2 to 3 cubic yards per hour.

Dry Washing Gold

Perhaps the most widely used dry recovery technique is dry washing gold, using a dry washer. The dry washer is basically a short, waterless sluice. It separates gold from sand by pulsations of air through a porous medium. Screened gravel passes down an inclined riffle box with cross riffles. The bottom of the box consists of canvas or some other fabric. Beneath the riffle box is a bellows, which blows air in short, strong puffs through the canvas. This gives a combined shaking and classifying action to the material. The gold gravitates down to the canvas and is held by the riffles, while the waste passes over the riffles and out of the machine.

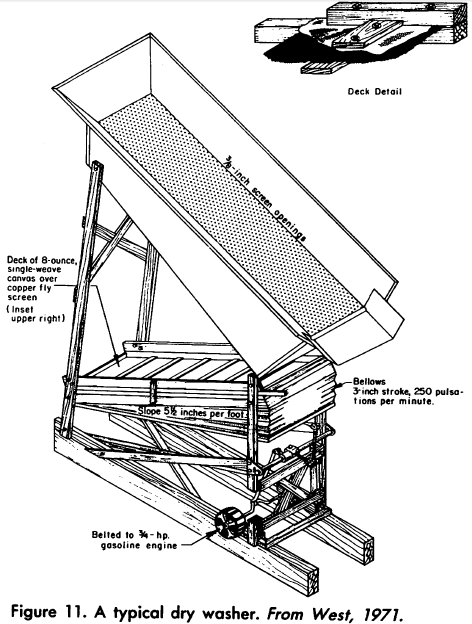

A basic dry washer is composed of a frame in which a well-braced, heavy screen is covered with burlap overlain with window or fly screen and covered with fine linen. Above this, riffles made of one-half to three-quarter-inch, half-round moulding or metal screen are placed 4 to 6 inches apart. The slope of the box varies from 4 to 6 inches per foot (Figure 11). If amalgamation of flour gold is desired, pockets to hold mercury are constructed in front of the riffles. A power washer of this type can process up to 21 cubic feet (approximately 0.8 cubic yards) of screened material an hour. Hand-powered washers operated by two men can process 1 or more cubic yards per 8 hours, depending on the size of the material handled.

For recovery of gold, the ore must be completely dry and disintegrated. If the ore is slightly damp below the surface, it must be dried before treatment. For small-scale work, sun drying will dry material about as fast as it can be processed. In operation, dry ore is fed into the vibrating screen of the dry washer where the fines fall through to the riffles and the oversize falls off the edge. The bellows and screen are operated by hand cranking or powered by a small engine. The bellows should be operated at about 250 pulsations per minute with a stroke of about 3 inches. These figures will vary with the coarseness of processed material and the fineness of the gold. Operation continues until about one cubic yard of material has been processed.

During cleanup, the riffle box is lifted out and turned over onto a large flat surface. The concentrates from the upper three riffles are first panned, and the gold removed. Usually the coarse and some fine gold can be saved here. The lower riffles may contain a few colors, but nearly all the recovered gold is caught in the upper riffles. The concentrates from the dry washer are further refined by panning or other means. If water is very scarce, the concentrates my be concentrated in the dry washer a second time and further cleaned by blowing away the lighter grains in a pan. Dry washers are portable, inexpensive, and easy to use. As with all dry placer methods, a large percentage of very fine gold is lost.

DRY WASHING

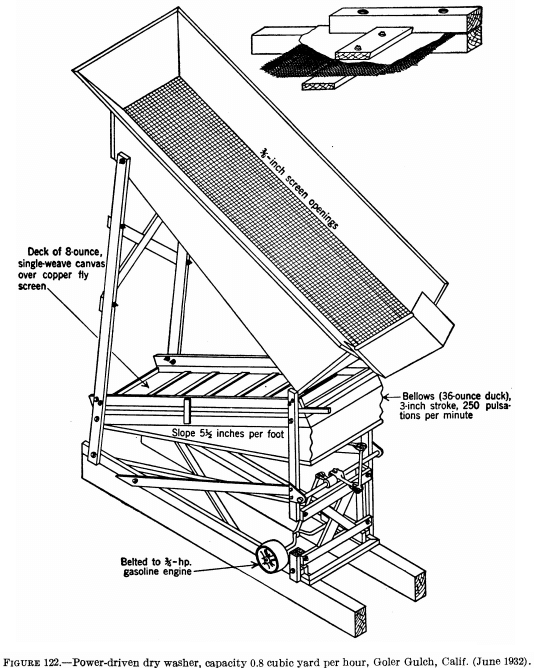

Dry washing usually has failed or been indifferently successful in this country. Winnowing as practiced in Western Australia, where the sand is very dry and there are strong prevailing winds, has not worked well here because of retained moisture in the sands and because of insufficient wind. For successful dry washing, the gravel must be completely dry and thoroughly disintegrated. Machines similar to

that shown in figure 122 consist of screens and flat-sloping, riffled canvas decks, under which air pulsations are produced by bellows or other means to agitate the sand and work it down the deck over the riffles, the gold and other heavy minerals being caught behind the riffles. The machine illustrated was operated to give 250 pulsations of air per minute, and the capacity was reported to be about 0.8 cubic yard per hour, bank measure.