The value of any series of experiments depends entirely upon the kind of sample of ore provided for the test. It must represent, wholly and completely, the character of the material that will be treated in the plant to be designed and constructed. If it does not, the tests will be useless or, worse, misleading.

In some cases, owing to conditions under which mining is carried on, it is considered advisable to remove a portion of valueless material by sorting before the ore is delivered to the metallurgical plant. No intelligent appraisal of the need for sorting or its extent can be determined from a laboratory sample, but it is essential that the test sample should represent accurately the character of the proposed mill feed, as to both precious-metal content and the proportions of barren material, wall rock, gangue, etc. All these factors are important, since they determine the sizes of equipment for settling, filtering, clarifying, and classifying as well as grinding equipment. These details are crucial and are essential parts of a complete investigation of possible metallurgical processes. Therefore, if sorting is to be done, the test sample should represent the ore after sorting.

The quantity of the sample is important in its bearing on the representative nature of the material. It should be sufficient to represent truly the character of the ore. Canadian custom, in 1950, was to ship from 500 lb. to 1 ton for tests. Where the material is unusually uniform, smaller amounts will serve as well.

In cutting down the sample and making separate portions for different methods of treatment, all possible care should be taken to ensure similarity of each portion. No care is too great to make certain of the representative character of the sample for testing. Consideration should be given also the abnormalities of ore feed that may be expected, owing to variations of the ore bodies being mined, to alter the average of usual character of the mill feed.

Various theoretical studies have been made to determine the minimum size of a sample cut for any specified degree of allowable error.

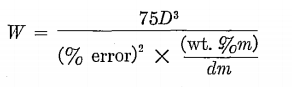

Reduced to its simplest terms, one accepted formula is: where W = weight of sample required in grams

where W = weight of sample required in grams

D = diameter in millimeters at which sample is 1.5 per cent plus

% error = error allowable (relative)

wt. %m = weight per cent of mineral m

dm = density of the mineral m

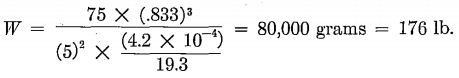

It is on gold ores carrying relatively coarse gold that the real problem arises, because the wt. %m is low and the dm is high. In ore assaying 0.1 oz. per ton, the wt. %m =4.2 X 10 -4% dm = 10.3. Thus if such an ore is to be sampled to 0.005 oz. ( = 5 per cent error) at 20 mesh, the sample to be taken is

This assumes the gold to be free and occurring in grains up to 20 mesh in size. For a 500-gram sample of this ore to be representative to a 5 per cent error, the ore would have to be crushed to 0.833/∛160 = 0.156 mm = 100 mesh approx.