Table of Contents

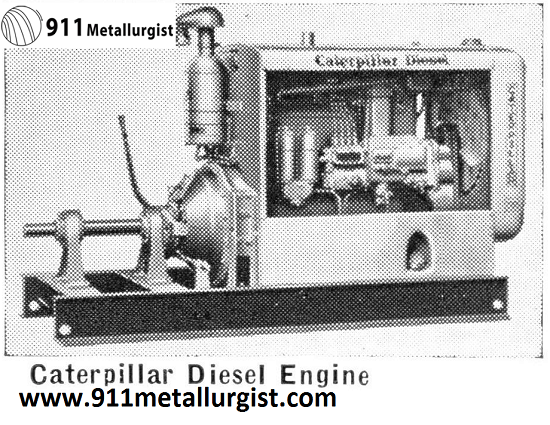

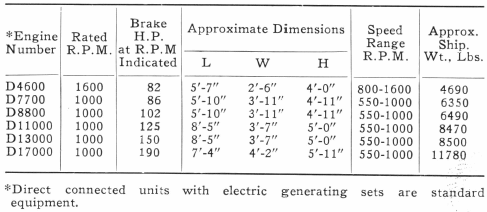

Engine, Diesel, Caterpillar

Caterpillar Diesel Engine brings to the users of small power units all of the advantages of the larger diesel engines.

The units are available in sizes from 52 horsepower to 190 horsepower and are all of rugged design with compactness and accessibility of parts built into all units. These engines are available in 6 and 8 cylinder sizes and with a speed range from 550 to 1650 R.P.M. The units are complete with totally enclosed clutches or open clutches, or without any clutch.

Included with these engines is an independent starting engine, air cleaner, and governor with 10% regulation (closer regulation governors are also available). Additional data gladly furnished upon request.

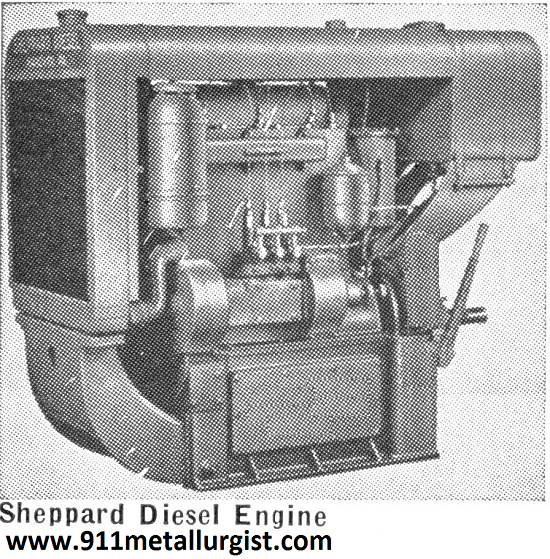

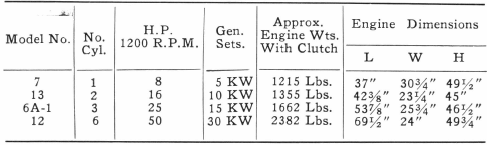

Engine, Diesel-Sheppard

The Sheppard Diesel Engine is a relatively new development in the diesel engine field. Built in five sizes, in the low horsepower range, it fills a real need for a quick, economical and dependable power source. This engine is available in 4, 8, 16, 25 and 50 H.P. sizes and can be furnished as a complete power unit equipped with a generator of suitable current characteristics to meet requirements.

All units are equipped with electric starters and are ready for installation to meet the operator’s needs.

Full advantage has been taken of all progress in diesel engine design since the development of this type of prime mover. Not only have all the recent improvements in the use of lighter alloys been incorporated in the design, but a new and simple fuel pump has been designed and is incorporated into the unit.

This diesel engine is an ideal stand-by unit for metallurgical or industrial plants where power failure may cause the loss of certain products in process. Where a shut down may cause settling out of pulps or products undergoing treatment, with the attendant delays in getting the equipment involved started up again, this unit would ensure a continuous power source.

Additional data gladly furnished upon request.

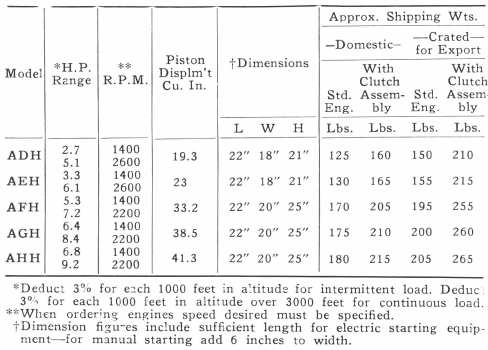

Engine, Gasoline, (Air Cooled)

(Air Cooled) Gasoline Engine, ranging in capacity from 1-9 H.P. is built to stand up under the hardest service with a minimum of upkeep, cost, and attention. It has a heavy, rugged crankshaft mounted on over-size Timken roller bearings; also a rotary high tension magneto with impulse coupling for easy starting in any kind of weather. The carburetor, equipped with automatic choke release, ensures foolproof starting. It is equipped with renewable valve seat inserts and built-in mechanical flyball type governor, giving close regulation and requiring no oiling or adjusting. A large fan, cast in the flywheel, supplies a blast of air which cools the engine under the most adverse conditions.

Engine weight can be reduced 30 to 40 pounds by having major parts cast in aluminum. Standard equipped to burn gasoline, these units also furnished to burn natural gas, fuel oil or kerosene.

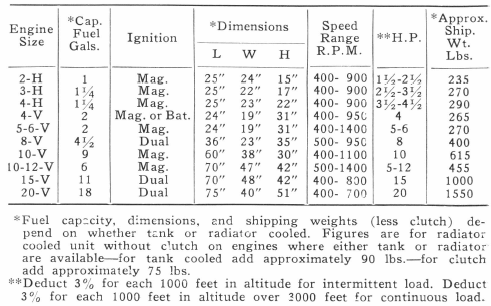

Engine, Gasoline, (Water Cooled)

Gasoline Engine (Water Cooled) is constructed to give continuous, economical operation. It is easy to start and operates with a minimum of vibration.

The 2, 3, and 4 H.P. engines are of the horizontal single cylinder type with over-size Timken roller main bearings, a high tension magneto, noned cylinder, and a hopper cooler. Cylinder, hopper and crankcase are all cast in one piece. Operates economically on gasoline and special equipment is available for adapting engines to use tractor fuel, kerosene, distillate or natural gas.

The 4 and 5-6 H.P. single cylinder vertical engines are self oiling and water cooled from either tank or radiator. These engines are precisely controlled by a sensitive governor and equipped with a high tension magneto and friction clutch pulley. Bearings and gears are fully enclosed in a dust and moisture proof crankcase and are readily accessible when side plate is removed.

In higher horsepower the 8, 10, 10-12, 15, and 20 H.P. engines are vertical double cylinder type with combination pump and splash oiling, high tension magnetos, taper roller main bearings and automobile type carburetion controlled by a throttling governor. These engines can be equipped with flat or V-belt pulleys or chain sprockets and with or without outboard bearing for heavy belt work. Friction clutch or pulley and long or short base optional. Equalized bearing load gives long bearing life. Water cooled from either tank or radiator.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.