Table of Contents

The Problem with Coarse Flotation and Recovery

Many flotation plants today are grinding to fine sizes. This means that money is being spent grinding worthless gangue which might be discarded at a coarser mesh. Many plants are treating ores in which the gangue is free at a coarse mesh and where a coarse bulk concentrate is economical. If the plant is using a flotation machine which can handle a coarse product such as the “Sub-A,” a slight change in the flowsheet may increase tonnage, improve recovery and lower grinding and reagent costs.

Flexibility, so important in the plant flowsheet, is also of utmost importance within the flotation machine itself. The ability to handle either a coarse or a fine mineral with no changes in equipment and with only minor changes in the flowsheet is one of the prerequisites of good concentrating equipment.

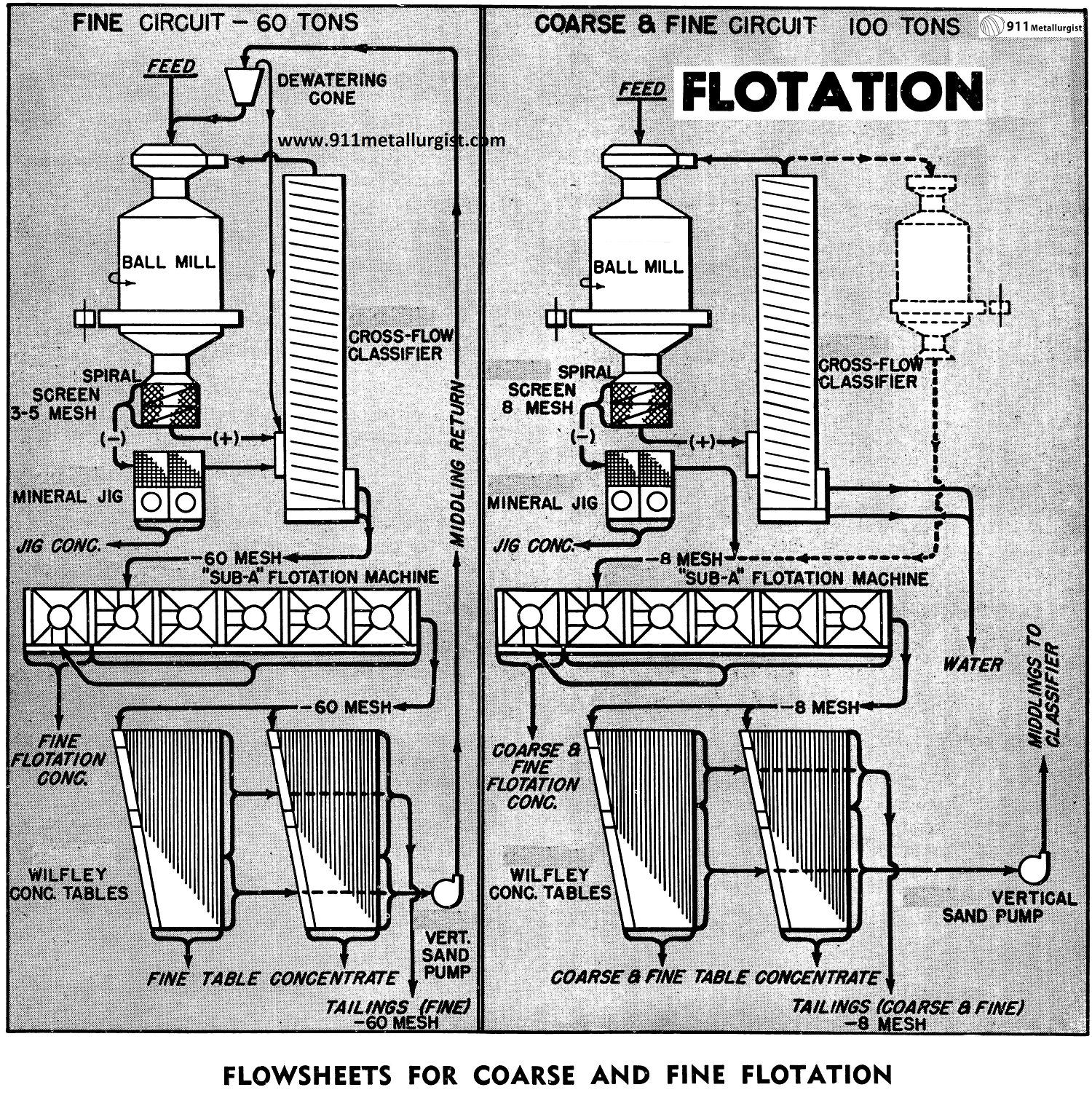

THE PROCESS FLOWSHEETS

Fine Flotation Circuit, 60 Tons/day

At the left in the flowsheets above is shown a conventional one-mineral or bulk separation using a classifier and a jig in closed circuit with the ball mill. This flowsheet was designed to handle a product at approximately 60 mesh.

Fine flotation flowsheets are used extensively when the gangue and the mineral are closely associated requiring a fine grind to free the mineral. Even under such conditions a Mineral Jig proves practical in the circuit to remove a middling product or free gold or other mineral ahead of the classifier. Due to the extreme selectivity of this jig, a high ratio of concentration can be made. Reports as high as many thousands to one have been received. The Mineral Jig requires little water and additional water must often be added to its discharge for proper and accurately controlled classification.

A six cell “Sub-A” Flotation Machine receives the fine overflow from the Cross-Flow Classifier. Due to closed circuit grinding and the close association of gangue and mineral, much of the mineral is very fine and overflows the classifier with the coarser, lighter weight gangue particles. Tailings from the flotation machine are fed to Wilfley Pilot Tables which give a continuous visual indication of flotation efficiency and become particularly important as recovery units when treating oxides or carbonates.

A Vertical Sand Pump returns a middling product from the table to a dewatering cone to provide a dewatered product for regrind purposes. The overflow from the cone may either be combined with fine overflow from the classifier or the feed to the classifier.

Coarse and Fine Flotation Circuit, 100 Tons/day

Using the same equipment in the same position a slight change in the flow enables both coarse and fine mineral particles to be recovered by the flotation machine.

The discharge from the ball mill in this coarse circuit passes over a spiral screen to the Mineral Jig for the removal of any coarse or free mineral. As the jig tailings are sent directly to the flotation machine, a slightly finer mesh screen is required on the ball mill than when a closed grinding circuit is used. Even with this fine screen, a much coarser feed goes to flotation than when only classifier overflow is being treated. The gravity flow principle of the “Sub-A” Flotation Machine allows this coarser feed to pass from cell to cell where both fine and coarse minerals are recovered in the concentrate, as the possibility of overgrinding has been eliminated. By avoiding overgrinding, as often occurs in the fine flotation circuit, grinding costs are lowered, reagent consumption is reduced, recoveries are increased and filtering improved.

The coarse and fine flotation tailings discharge across pilot tables which assume a more important function as a larger quantity of coarse middling product must be produced. The sand pump returns this middling product to the head of the circuit feeding the classifier which now acts primarily only as a dewaterer. The sand product is returned to the ball mill and the overflow, being nearly clear water, can be reused in the mill circuit. Due to this open circuit arrangement and as a coarse and fine waste or tailings is discarded by the tables, the capacity of the ball mill is increased from approximately 60 to in the neighborhood of 100 tons. Why regrind to a fine size a worthless gangue product that can be removed from the circuit?

A regrind mill may be used to grind the classifier sands and its product added to the discharge of the primary mill. This further increases plant capacity. The capacity of the flotation machine as used in the fine circuit is at least doubled in the coarse circuit and when a regrind mill is used.

An outstanding feature of the “Sub-A” Flotation Machine is its ability to handle a coarse feed. This is made possible by its exclusive “gravity flow” principle and wearing parts of moulded rubber specially bonded to steel cores.

Many important advantages result from the use of a coarse and fine flotation circuit over one employing flotation of the mineral in only the fine sizes.

- Grinding costs are lowered.

- Greater capacity is obtained with same equipment.

- Production of a coarser concentrate means easier de-watering and filtering.

- By doing away with overgrinding, sliming and colloiding are cut to a minimum which benefits flotation materially.

- Lower reagent costs.

Careful study should be made when designing a mill to take advantage of flexibility available, especially in a properly designed flotation machine, so that the flowsheet itself will have the highest possible degree of flexibility.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.