Table of Contents

- Beneficiation of Copper Sulfide by Flotation

- Flowsheet for treatment of Copper Sulfide ores rich in minerals such as chalcopyrite with gold and silver as well as arsenopyrite

- The Problem with Flotation of Porphyry Coppers

- The Porphyry Copper Extraction Process Flowsheet

- Summary of Porphyry Copper Sulfide Processing

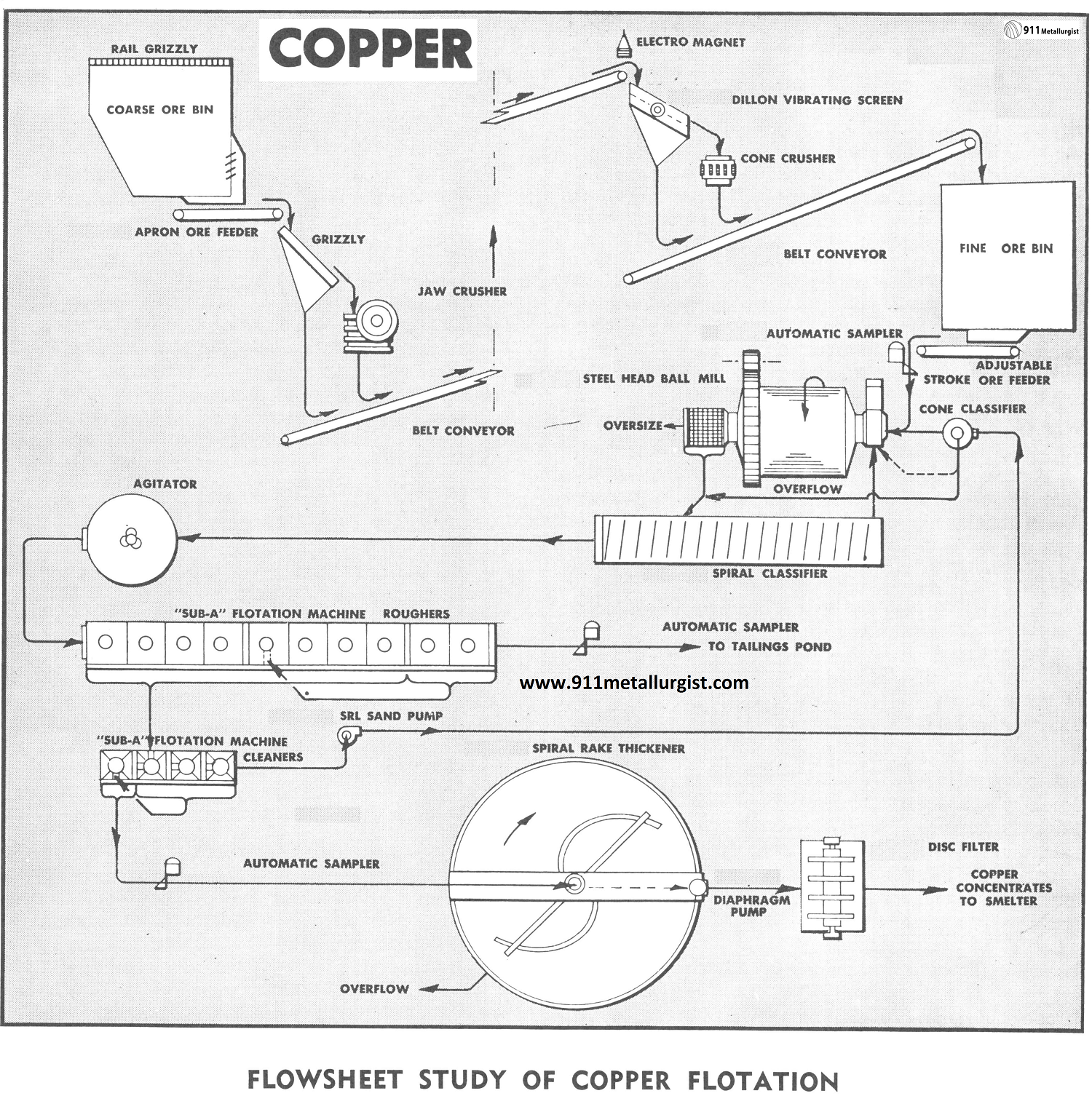

- The Copper Process Flowsheet

- Summary of the copper sulphide ore recovery process

Copper Sulfide Flotation Circuit

Beneficiation of Copper Sulfide by Flotation

Copper, due to the present world demand and price, is of foremost interest to the mining industry. Many new properties are either in the process of being brought into production or are being given consideration. Copper minerals usually occur in low grade deposits and require concentration prior to smelting. The method and degree of concentration depends on smelter location and schedules, together with the nature of the ore deposit. Sulphide copper ores generally occur with pyrite, pyrrhotite, arsenopyrite and molybdenite, and with gold and silver. A complete copper-iron separation may not always be essential for the maximum economic recovery and often is tied to the distribution of the gold and silver values.

Flowsheet for treatment of Copper Sulfide ores rich in

minerals such as chalcopyrite with gold and silver as well as arsenopyrite

The above flowsheet is designed for the treatment by flotation of copper as chalcopyrite with gold and silver values. The ore, ranging from 60-65% silica, with pyrite, arsenopyrite, and calcite with 3 to 4% copper. This flowsheet, though simple, is adequate for tonnages of 100 to 500 tons or more per day, depending on the size of equipment selected. It can be readily expanded by duplicating units for increased tonnages. By minor circuit changes, it provides the flexibility to treat a range of ore conditions which are often encountered in any mining operation. Generally in these small plants the recovery of molybdenum is disregarded unless it is present in considerable amounts. Larger plants generally will incorporate a circuit for molybdenum recovery from the copper concentrate by flotation. “Sub- A” Flotation is standard for this service.

Crushing Section. The crushing section with two-stage reduction is suitable for smaller tonnages, depending on the ore characteristics. Three-stage reduction in either an open or closed circuit, with screens for the removal of fines can be employed where conditions warrant. The fines are removed by a grizzly or screen ahead of each reduction stage for higher efficiency and for reduced wear on crushing surfaces.

An electro-magnet for removal of tramp iron is placed over the feed conveyor to secondary crushing. A magnetic head pulley would also be suitable.

Copper Ore Grinding Circuit

Feed control is essential to efficient grinding and helps reduce surges and fluctuations throughout the entire plant. The Ball Mill in closed circuit with a Spiral Classifier discharges the pulp at about 60% minus 200 mesh. The Ball Mill is equipped with a Spiral Screen on the discharge for removal of any tramp oversize, worn grinding balls, and wood chips from the circuit.

Copper Sulfide Flotation Circuit

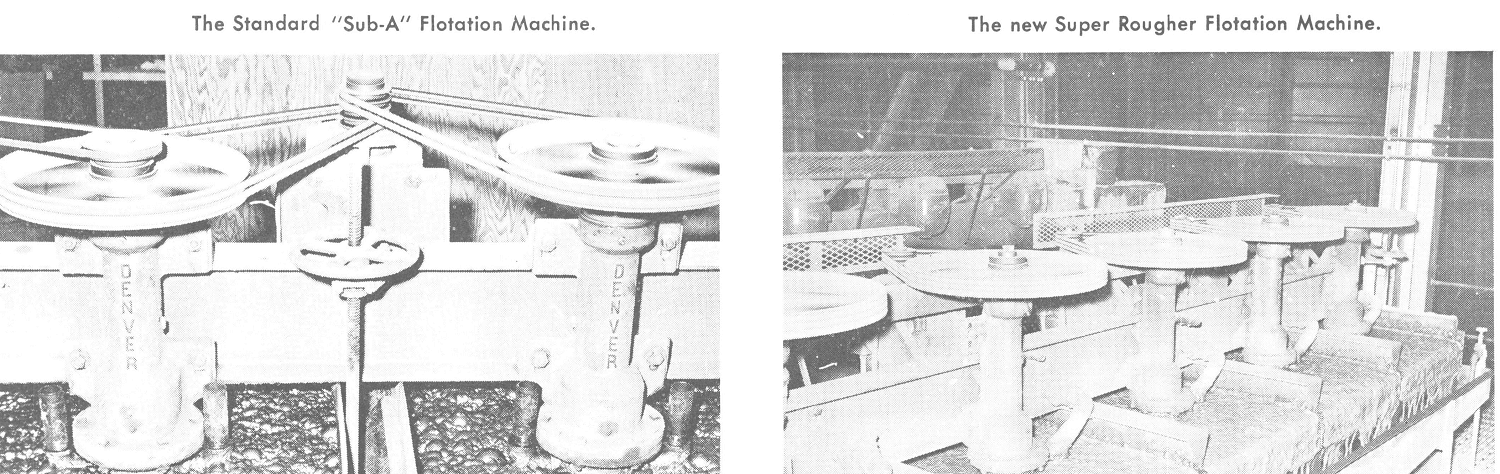

The pulp from the Conditioner is treated in a 10-cell “Sub-A” Flotation Machine and a 4-cell “Sub-A” Flotation machine. Sometimes conditioners are not provided; however, their use insures that reagents are thoroughly mixed into the pulp ahead of flotation. This gives a more uniform feed and effective use of reagents plus improved flotation conditions. The 10-cell “Sub-A” Flotation Machine is of the “free-flow” type. Weirs for the control of pulp level through the machine are provided at the fourth, eighth and tenth cells. This “free-flow” type provides ample volume for normal fluctuations in the feed rate without cell level adjustment. Sand relief ports help extend the long life of the molded rubber wearing parts.

The first eight cells produce a rougher concentrate while the last two cells act as scavengers. The concentrate or middling product from these two cells is returned by gravity back to the fifth cell. The rougher concentrate from the first eight cells is cleaned in two stages in the four-cell standard “Sub-A” Flotation Machine, of the cell-to-cell type. No pumps are needed for the return of these flotation products for cleaning. This feature in “Sub-A” Flotation Machines gives added flexibility by enabling the operator to change cleaning circuits readily, should conditions require. The tailings from the cleaner flotation section are pumped back to the ball mill for regrind. To control dilution a cone classifier is placed in this circuit with the coarse solids going to regrind and the overflow used as dilution in the mill and classifier. It is possible to eliminate this classification in some cases but control is less positive. A separate regrind section could be provided if the quantity of middling products were enough to make this section feasible.

Copper Concentrate Thickening and Filtering

The final cleaned flotation concentrate flows or is pumped to a Spiral Rake Thickener. A Adjustable Stroke Diaphragm Pump, mounted on the thickener superstructure, meters the thickened concentrate to the Disc Filter. The Thickeners are often used to store concentrates for filtration at fixed intervals. These units have heavy duty construction throughout, overload indicators and positive rake lifting features. The Diaphragm Pump is used for concentrate recirculation purposes during such periods.

Copper Sulfide Flotation Reagents

Lime is added to the Ball Mill by a Cone Type Dry Reagent Feeder. Other reagents, such as cyanide, xanthate, and a frother are fed and controlled by No. 12A Wet Reagent Feeders to the classifier and to the conditioner ahead of flotation.

Sampling. Automatic Samplers are provided for the sampling requirements. The use of these samplers eliminates the human factor and assures the accuracy needed for control and evaluation.

Summary of the Copper Extraction Process

This flowsheet stresses simplicity without sacrifice of efficiency. The factors of flexibility are essential to meet changing ore and market conditions. The unit arrangement which can be expanded by sections for increased capacity is an important feature. The equipment indicated has been proven for long life and low maintenance, and to give superior results. The “Sub-A” Flotation Machines are designed for high capacity and with features of flexibility to handle fluctuating conditions with a minimum of operating attention. Low final tailings and high grade concentrate are assured through the selective action of the “Sub-A” in the roughing, cleaning, and recleaning circuits.

Copper Facts

- Atomic number (number of protons in the nucleus): 29

- Atomic symbol (on the periodic table of elements): Cu

- Atomic weight (average mass of the atom): 63.55

- Density of copper: 8.92 grams per cubic centimeter

- Phase at room temperature: Solid

- Melting point: 1,984.32 degrees Fahrenheit (1,084.62 degrees Celsius)

- Boiling point: 5,301 degrees F (2,927 degrees C)

- Number of isotopes (atoms of the same element with a different number of neutrons): 35; 2 stable

- Most common isotopes: Cu-63 (69.15 percent natural abundance) and Cu-65 (30.85 percent natural abundance)

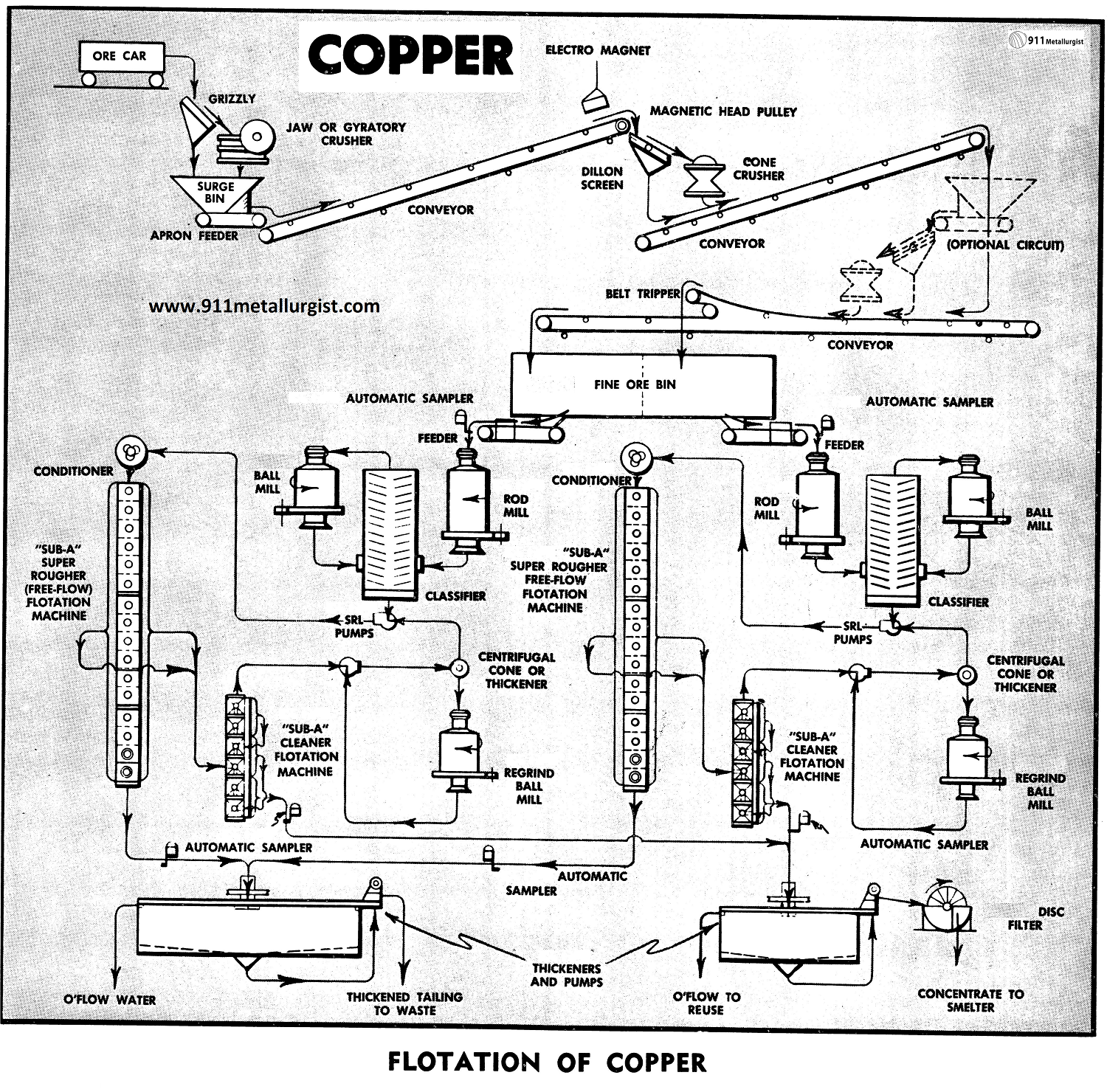

The Problem with Flotation of Porphyry Coppers

Large scale mining operations, of which the porphyry coppers are typical, must resort to concentration. This is necessary as the ores are generally low grade and require flotation to produce a concentrate acceptable to the smelters.

These large scale milling operations handling low grade ore must provide very careful planning in the design of their plant flowsheet and selection of equipment. Milling circuits must be as simple as possible and for large tonnages, as few as possible. It is for this reason grinding mills and flotation circuits are now designed to handle these large tonnages at low cost.

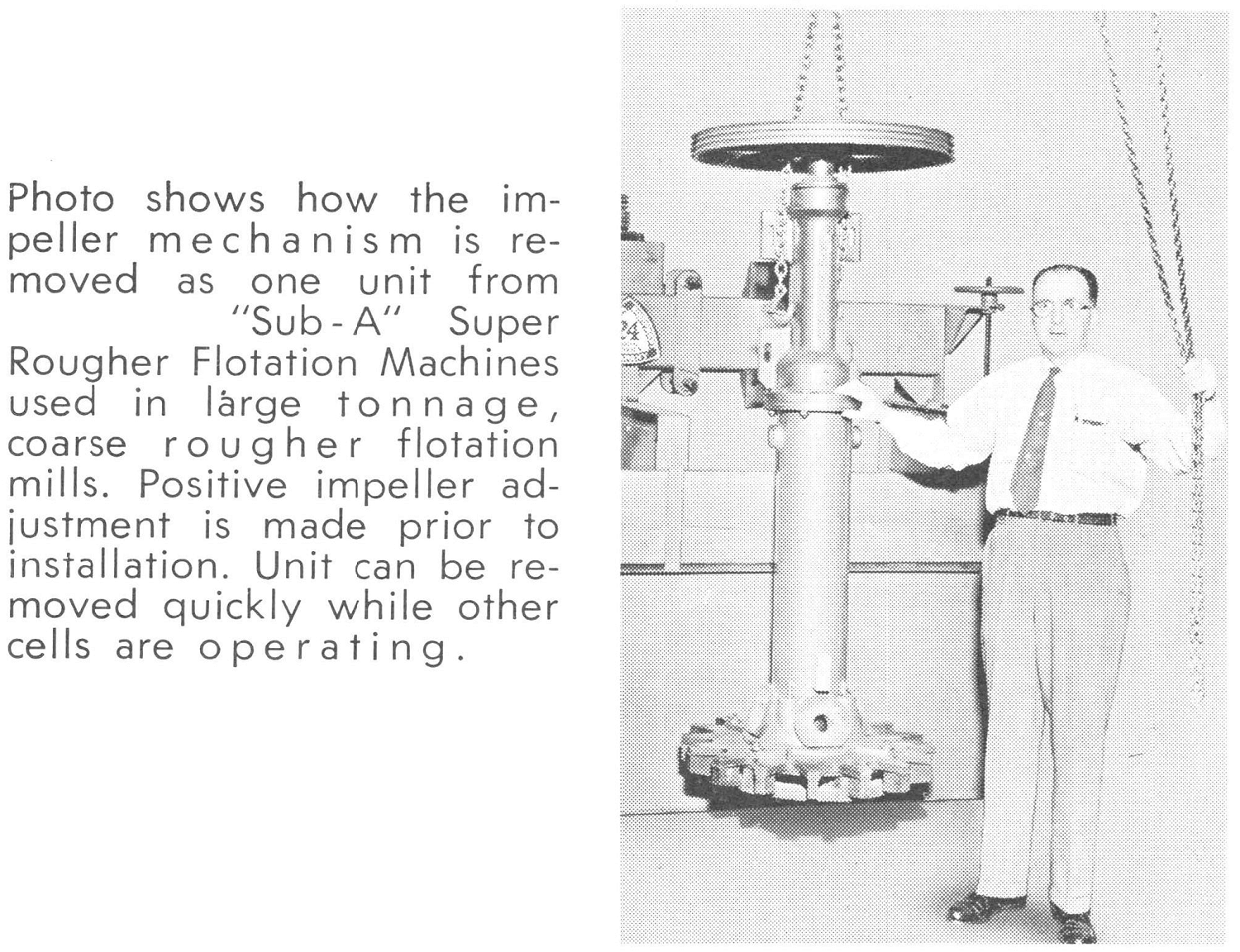

“Sub-A” Flotation Machines are a basic part of large tonnage operations and their use assures maximum economic recovery. Particular emphasis has been placed on the design and operation of these machines for roughing, scavenging and cleaning. Mechanisms have been greatly simplified and molded rubber wearing parts are standard for maximum abrasion resistance.

The flowsheet presented in this study is typical for large tonnage installations and incorporates latest developments in modern milling practice.

The Porphyry Copper Extraction Process Flowsheet

Crushing Porphyry Copper Ores

Three stage crushing is illustrated in the flowsheet; however, it is possible and practical to eliminate the third stage by incorporating a rod mill in the grinding section. This is a very practical arrangement and often a necessity when handling wet, sticky ore. There is evidence that this combination of crushing and grinding results in lower costs for reducing large tonnages of ore to flotation size.

Grinding Porphyry Copper Ore

The flowsheet illustrates a typical grinding circuit with a rod mill in open circuit. Its discharge, usually all —14 mesh, goes to a classifier for removal of finished material. The classifier sands are ground in a ball mill in closed circuit with the same classifier. High speed rod milling with speeds up to 80% of critical has shown definite improvement in efficiency and grinding capacity. Proper selection of mill density and grinding charges are also factors of importance. Usually the rod mill is operated at lower density so it acts partially as its own classifier for retaining oversize for further size reduction.

A middling regrind circuit is provided in the flowsheet and is essential for assuring maximum grade of concentrates and low final tailings.

Conditioning Copper Ore for Flotation

Some conditioning of the pulp ahead of flotation is usually very beneficial and will result in more uniform and rapid flotation of a selective high grade concentrate. For this service the (patented) Super Agitator and Conditioner is standard. Reagents added at this point are thoroughly mixed and reacted with the pulp. Any tendency of the pulp to froth prematurely is readily overcome by the patented standpipe arrangement which also assures positive pulp circulation.

Copper Rougher Flotation

For large tonnage circuits normally encountered in many of the copper operations the open or free flow type “Sub-A” Super Rougher Flotation Machine is recommended. Intermediate cell weirs are eliminated and circulation of pulp through the impeller is fixed to provide the desired agitation and aeration for rougher flotation conditions. Machines are usually arranged with up to six cells being open or free-flow without intermediate weirs. Two or more machines are always provided in series. This allows adequate volume for absorbing surges and fluctuation in feed without cell adjustment. Mineral and middlings in the teeter or quiescent zone of the cell are gradually forced upward to the froth removal zone. Only the coarser material in the agitation zone passes through the impeller for further conditioning and bubble attachment.

In the flowsheet each circuit consists of 16 or 18 cells in 4 or 6 cell units. These “Sub-A” Super Rougher Flotation Free-Flow Machines are in series. All of the mechanisms are of the single impeller type and are completely supported from the superstructure to facilitate maintenance. All heavy hoods and castings are eliminated and the impeller-diffuser clearance is pre-set and accurately maintained throughout the long life of the heavy duty moulded rubber wearing parts. The last two cells are the super scavenger type giving very intense agitation and aeration to float the last trace of recoverable mineral or middling for re-treatment.

Horsepower input into the rougher – scavenger system is set for most efficient operation and is adjustable to actual ore treatment requirements depending upon agitation and aeration conditions.

Copper Cleaner Flotation

Rougher flotation concentrates are cleaned in a standard “Sub-A” Flotation Machine with cell to cell pulp level control. This arrangement for upgrading concentrates is universal in its acceptance by the ore dressing industry. Two or more stages of cleaning in the same machine are accomplished without auxiliary pumps and ideal flotation conditions for producing high-grade concentrates are easily maintained.

Cleaner flotation tailings are returned to the head of the rougher flotation circuit for retreatment. In many milling circuits, particularly if coarse grinding is used, the cleaner tailings will contain middlings or mineral with attached particles of gangue. In these cases it is necessary to thicken or classify and regrind this fraction. Centrifugal classifiers are being very successfully applied for the classification step although they do take considerable power and require more maintenance than a thickener with its underflow going to a regrind circuit.

Thickening and Filtering of copper concentrates

The flowsheet incorporates thickening for both the concentrates and tailings for water reclamation and tailings disposal purposes. A Adjustable Stroke Diaphragm Pump on the concentrate thickener assures absolute control of the volumes delivered to the Disc Filter. When the filter is down temporarily for bag changes the concentrates may be recirculated to the thickener by this same pulp.

Summary of Porphyry Copper Sulfide Processing

Flexibility and simplicity are the two most important points to design into any large tonnage flotation operation. The arrangement shown is flexible and will permit addition of extra milling sections up to the limit of the designed capacity of the crushing plant. “Sub-A” Flotation Machines are designed specifically for high tonnage installations and have been proven for all types of applications. Rugged construction will give years of service at lowest possible cost. This flowsheet is readily adaptable for the treatment of other ores. Note particularly the location and use of Automatic Sampler.

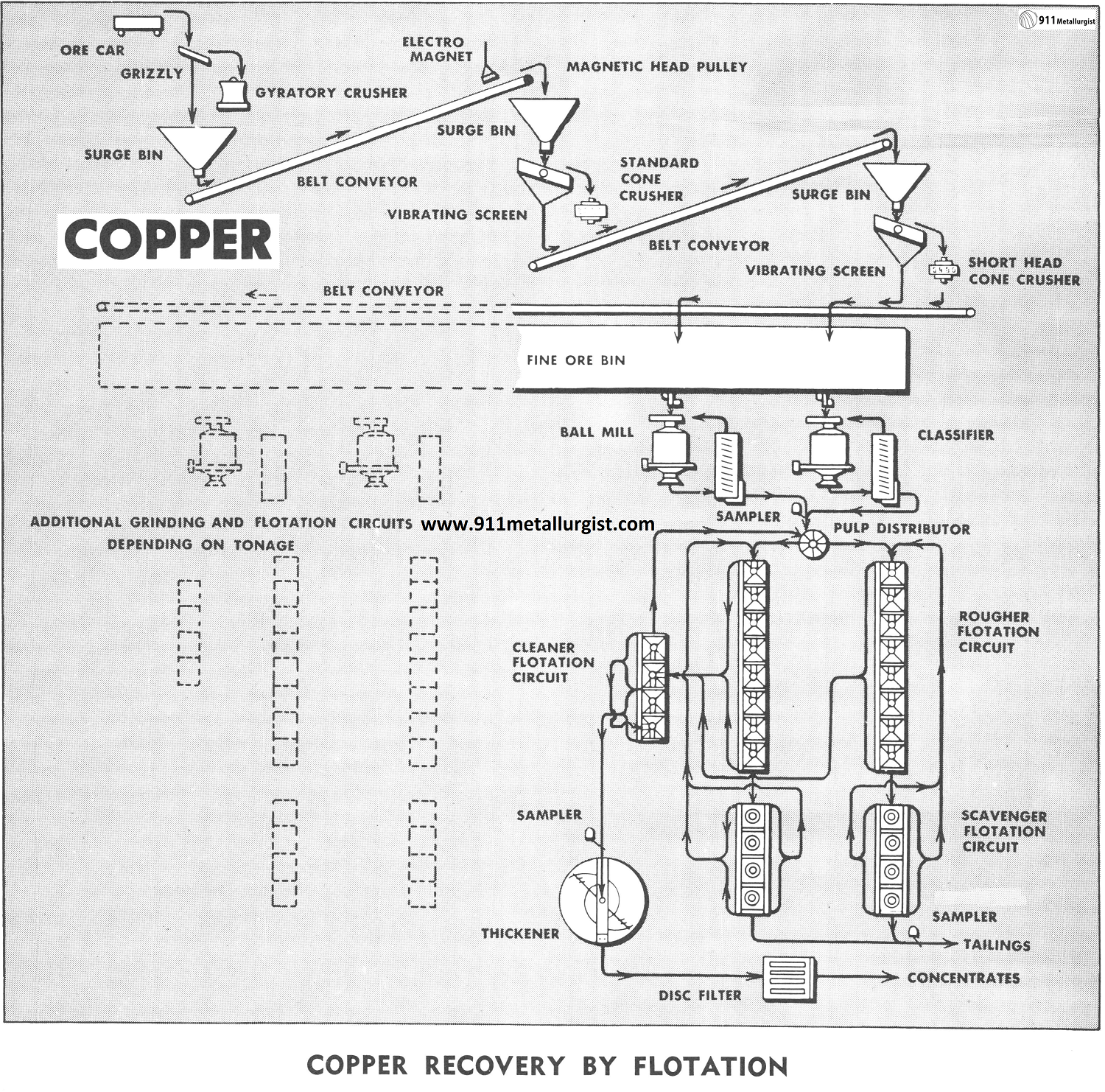

The Problem with Copper for Porphyry ores and Chalcocite and Chalcopyrite

The Problem with Copper for Porphyry ores and Chalcocite and Chalcopyrite

Copper, one of our most important minerals, is found in many parts of the world. One of the major sources of Copper is the so-called porphyry ores such as the large deposits in the west and southwestern United States, Mexico, South America and Europe.

Porphyry ores, with copper occurring in the form of Chalcocite and Chalcopyrite are normally low in grade and the copper minerals must be concentrated before smelting. In this flowsheet using “Sub-A” Cells the emphasis is on maximum economic recovery—high concentrating efficiency together with a premium smelter feed with a low alumina and magnesia content in the flotation concentrate.

To obtain lowest tailings from this ore usually requires scavenging of rougher flotation tails. This is performed ideally by the “Sub-A” Super Rougher Flotation Machine which was specially developed for this duty. This machine has a double impeller and gives tremendous aeration.

The flowsheet in this study is designed to get the maximum recovery from a large tonnage of porphyry copper ore.

The Copper Process Flowsheet

Copper Ore Crushing

The crushing section consists of three-stage ore reduction with either a grizzly or vibrating screen between each crushing stage. Removing fines before putting the ore through a crusher increases the efficiency of the crusher as it is then only working on material that must be reduced, and is not hampered by fines already reduced in size. Electromagnets and magnetic pulleys are used to remove tramp iron from the ore, the former to remove the iron near the surface and the magnetic pulley to remove the tramp iron close to the conveyor belt.

Copper Ore Grinding

Porphyry copper ores usually are medium to medium hard and require grinding to about 65 mesh to economically liberate the copper minerals from the siliceous gangue. Sometimes a regrinding circuit is advantageous on the rougher concentrate and on the scavenger concentrate. This will liberate the mineral from the middling products and increase the recovery by putting those mineral particles into the concentrate. Rougher flotation may be accomplished at a relatively coarse grind and the subsequent regrind performed on a comparatively small tonnage.

Copper Flotation Reagents

Lime is usually added to the ball mill feed by a Dry Reagent Feeder. The frother and promoter are added in the classifier prior to flotation to realize the full effect of the reagent. Reagents can also be stage- added to the cells in the flotation circuit.

Flotation of Copper Minerals

Standard “Sub-A” Flotation Machines are used for both the rougher and cleaner circuits, where their cell-to-cell principle gives both high recovery and a good grade of concentrate. The rougher concentration is accomplished in 6 or 8-cell flotation machines, with the concentrate from each going to a separate bank for cleaning and re-cleaning. No. 30 “Sub-A” Flotation Machines are ideal for large tonnage operations, as each bank will handle from 1000 tons upward per day. Tails from the rougher circuit go to a scavenger circuit. Roughing, scavenging, cleaning and recleaning can be carried out in one bank of “Sub-A’s”. This is possible because of the distinctive gravity return of a product from any cell to any other cell of a bank without using pumps. In large installations, however, these steps are usually carried out in separate banks of cells. The scavenger flotation circuit consists of a 4-cell, “Sub-A” Super Rougher Flotation Machine with its super aeration. The concentrate from scavenger cells is returned to the head of the rougher cells and tails are sent to tailing pond. The new “Sub-A” Super Rougher Machine is designed especially to produce the lowest possible tailings in the mill circuit by scavenging off the last bit of recoverable and often “difficult to float” mineral. The Automatic Sampler is used on the flotation feed, concentrates and tailings to establish close mill control.

Thickening and Filtering of copper sulphide concentrate

The flowsheet incorporates a thickener on the copper concentrates to thicken for optimum filtering. This also serves as a temporary storage space to accommodate operating requirements. The Adjustable-Stroke Diaphragm Pump on the thickener gives absolute control of volumes pumped to the filter. When the filter is shut down concentrates may be recirculated to the thickener by this same pump.

Summary of the copper sulphide ore recovery process

It is essential to have flexibility in any mill circuit, but particularly in large-tonnage operations such as this. Changing ore, changing market conditions and many other factors make this flexibility absolutely necessary. A slight change, easily made, in a flexible flowsheet may increase tonnage, improve recovery and lower grinding and reagent costs.

https://www.911metallurgist.com/copper-pyrite-flotation

- Copper-Competitiveness

- Copper-Industry-and-Market-Structure

- Copper-Market-Structure

- Copper-Production-Technology

- Copper-Resources-and-Technology

- COPPER

- Energy-Use-in-the-Copper-Industry

- Environmental-Aspects-of-Copper-Production

- Strategies-for-Future-Competitiveness-of-Copper

- The-Business-Structure-of-the-Copper-Industry

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.