A very unique and simple way of measuring or comparing the amount of air that is working its way up through the pulp of any flotation cell is as follows:

- A 500 cc or 1000 cc graduated cylinder (smaller size should be used if test is to be made on a laboratory size cell).

- A stop watch or ordinary watch with a second hand.

PROCEDURE

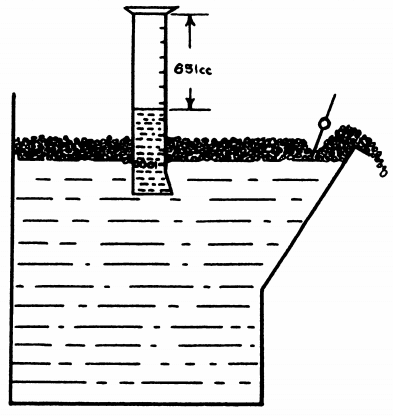

Fill the graduate completely full of water, seal top with hand, invert into cell being tested, submerging the top of the graduate about 3 or 4 inches.

Check time and remove hand, allowing air to bubble up into the cylinder and displace water.

Be sure to move the cylinder around over the entire surface of the cell to get an average reading.

Use time of 0.5 minute or 1 minute as desired. (If for 0.5 minute, double cubic centimetres displaced.)

At end of predetermined time, reclose graduate with hand.

Read actual displacement.

Now measure the inside diameter of the graduate, determine area and convert to square inches.

Divide displaced water in cubic centimetres by the area of the cylinder in square inches and the answer in cc air per square inch per minute.

EXAMPLE: Actual test on 18 Special Supercharged “Sub-A” flotation cell.

Cylinder, 1000 cc size.

Cylinder Diameter = 2 3/16″ inside.

Cylinder Area = 3.756 square inches (d2 pi)/4

Water displaced in l/z minute = 631 cc

Water displaced in 1 minute = 1262 cc

1262/3.756 = 336 cc per square inch per minute.

1000 cc. graduated cylinder. For laboratory size flotation machines, a smaller graduate should be used. Submerge graduate 3 or 4 inches below froth column.

1000 cc. graduated cylinder. For laboratory size flotation machines, a smaller graduate should be used. Submerge graduate 3 or 4 inches below froth column.

If this is not fancy enough for you, you can always use the very complex method found in Analysis of Air and Frother Profiles in Flotation

Banks.