Table of Contents

In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone crusher the usual practice was to make a 2-in. product in two steps consisting of a primary breaker of the jaw or gyratory type followed by a secondary gyratory crusher. If anything smaller were desired, a third stage was added comprising coarse crushing rolls in closed circuit with a screen. The Symons cone crusher, however, will take the discharge of the primary breaker and crush it to 3/8-in. size in one pass more cheaply and efficiently than is possible with rolls. A screen is usually placed ahead of the cone crusher in order to bypass material that is already small enough and so to relieve it of unnecessary work, but there is no necessity to screen the discharge, as must be done in the case of rolls; the crushing elements are so designed that the finished product is made in one pass through the machine.

Modern practice, then, is to crush the ore as it comes from the mine in two steps to a maximum size of ½” without the use of water except as a spray to remove dust. Three stages are only needed if the primary machine is called upon to take lumps of exceptional size, such as are encountered when mining is done by power-shovel. Since this material is very difficult to handle through a bin gate, it is usual to feed it direct to a specially large preliminary crusher, often of the jaw type, which breaks the ore to a size small enough to enter the normal primary crusher.

Crusher Plant Layout

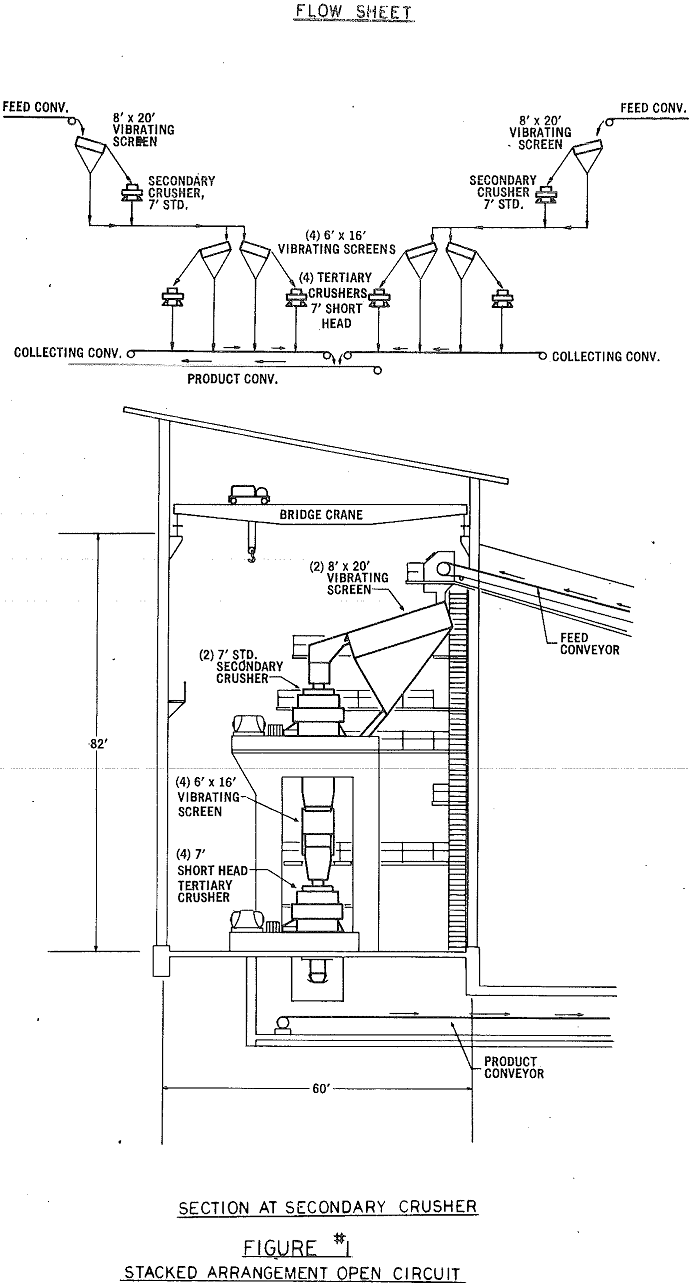

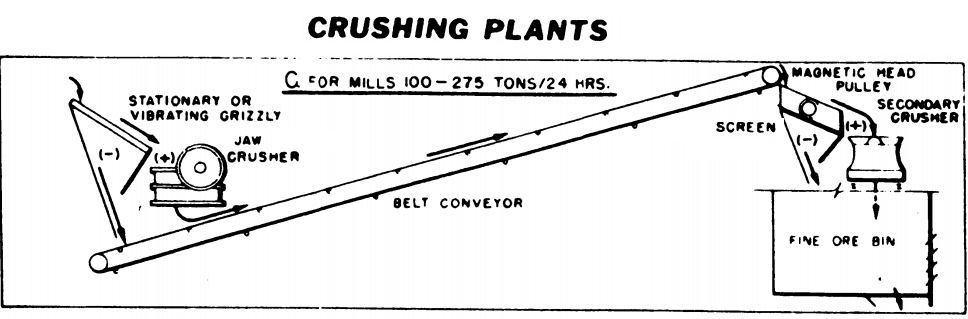

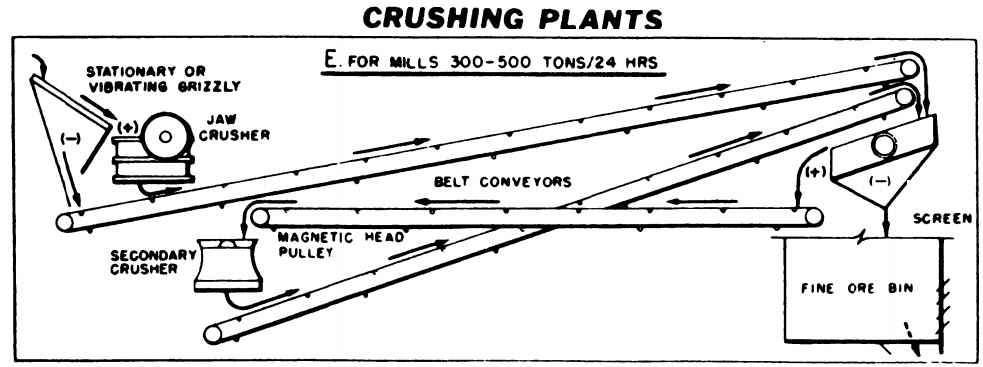

Most crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement.

The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant and of the gyratory type in the case of a large one. The reduction ratio—that is, the ratio between the “ inch size ” of the largest lump entering the machine and that of the largest piece leaving it—is usually between 4 and 6 to 1 for either machine.

The undersize of the grizzly joins the product of the primary breaker and is transported by a belt conveyor to an intermediate bin, from which an automatic feeder delivers it to an elevating belt conveyor discharging on to a vibrating screen. The screen by-passes any material fine enough to enter the grinding section and delivers the oversize to a cone crusher, the discharge of which joins the undersize of the screen and is taken by a belt conveyor to the fine ore bin ahead of the grinding section.

The fine ore bin can be designed to hold two days’ supply of ore, but the coarse ore bin should not hold more than one day’s supply on account of the tendency of large lumps to pack under pressure of a heavy column of ore. The intermediate bin with the automatic feeder and belt conveyor following it are occasionally omitted, but the practice is not to be recommended, since the discharge of the primary breaker then passes straight to the vibrating screen and cone crusher, with the result that the unavoidable irregularities of feed in the first stage pass on to the second ; moreover, the correct rates of feed for the primary and secondary machines are seldom the same. Therefore, as a cone crusher can only be run at maximum efficiency if it is given a regular feed at approximately the correct rate, it is best in the interests of efficiency to retain the intermediate bin.

A group of several automatic feeders at intervals along the length of the bin are sometimes required to keep the larger sizes of gyratory crushers running at full capacity. The layout of a large installation, especially one with several primary breakers, is consequently not always quite as simple as the foregoing description would indicate on account of the greater complexity of the conveyor system. The usual method of handling the ore is to arrange for each group of feeders to discharge on to one particular apron conveyor running parallel to the bin under the projecting ends of the feeders; the conveyor in turn discharges on to a belt conveyor which elevates the material to the appropriate primary crusher. It should be understood that the limiting factor is the maximum possible height of the bin ; an automatic feeder can be made big enough to supply the largest crusher, but it is not always possible to provide sufficient bin height to give the necessary storage capacity over a single feeder. A longer bin with a greater number of feeders is therefore the usual alternative.

For three-stage crushing, the preliminary stage is frequently a duplication of the first step of the two-stage arrangement shown in Fig. 1, but it is not uncommon for the first machine to be placed near the scene of mining operations if the mine is situated at a considerable distance from the flotation plant.

The advantages of producing a fine mill feed have been recognized for many years. The extent to which fine crushing can be carried out will vary and depends on the ore characteristics, plant and crusher design. Unfortunately, the ore characteristics are generally beyond our control, so the concentration of effort lies primarily on the plant arrangement, equipment design and operation. Where fine crushing should stop and grinding begin is controversial and is influenced greatly by personal opinions and experiences. Often, this break point will be different if consideration is being given to a new plant in comparison to a modest expansion. Most new plant designs employ the largest and most efficient equipment. The modification of existing plants becomes more complex because of the space requirements and the related equipment already in operation.

Fine crushing is, of course, a relative term. Obtaining a final crusher product of minus ¾” is commonplace today and can occasionally be obtained in an open circuit final crushing stage.

As the need for finer crushing increases, consideration must be given to the achievement of maximum crushing and screening efficiency. The majority of crushing plants recently constructed have accomplished this desired efficiency by optimizing plant design, crusher design and automation. By improved efficiency a decrease in energy consumption per ton of crude milled should be achieved. Further savings resulting from finer crushing are realized in the concentration or mineral recovery phase of a process. These benefits are rather difficult to quantify due to the varying complexities of the concentrators and benefication processes. Relatively clear and measurable are the metal and maintenance costs and the ever increasing cost of energy. Metal costs in the form of crusher liners have not quite doubled in the last 20 years, while power costs have increased by a factor of four or five depending on the region considered. Estimates made only a year ago on the increased cost of energy are obsolete in view of the recent unstable conditions in the Middle East. Since power is, therefore, becoming the largest cost area, it behooves us to investigate potential cost saving methods in the form of lowering the KWH/TON of crude. This discussion will confine itself to conventional crushing and grinding existing technology and equipment.

Crushing

To reduce run-of-mine to mill feed requires reduction in a series of stages. The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application. Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushing. In the majority of cases, the last crushing stage is closed circuited using anywhere from 10MM (3/8″) square to 14MM (9/16″) slotted openings on the sizing deck. In some copper concentrators, the mill feed is all passing 13MM(½”), using three stages of crushing and 14MM (9/16″) square openings on the closed circuit screens. It was felt by some that crushing to this fine size is only possible if the ore is friable and is relatively soft in comparison to the harder ores. Our results show that some of the copper ores are as hard as taconite and are crushed to ball mill feed all passing 13MM (½”).

Even when a crusher has the capability of achieving a high reduction ratio it is normally more efficient to run the crusher at a mid-setting, as shown in the manufacturers tables, rather than choosing the closest setting which offers the greatest reduction ratio. The main consideration at each stage for maximum production is efficient power draw.

There is an optimum setting for each crusher and an optimum number of stages required for maximum plant production based on the individual characteristics of the material being crushed. Overloading the crusher does not increase production, but instead is counterproductive and will decrease the lives of the crusher components. Ideally, the topsize feed should receive four to five impact blows during its progress through the crushing chamber. This is a combination of reduction at the upper zone of the liners as well as the parallel zone. The crusher should be fed so as to be operating at or near continuous full load horsepower capability. Operating the crusher at too narrow a setting decreases capacity and creates high wear. Too wide an opening, in proportion to topsize feed, will prevent crushing in the upper zone and will develop excessive power draw. Power drawn per ton of crusher feed is not in itself a measure of productivity. Efficient use of power through proper application of the cavity, with respect to feed and product requirements, will determine the optimum production per horsepower drawn. From the following crusher application descriptions, it can readily be seen that each crusher has its own designed level of reduction. The range of feed sizes and product sizes, for each crushing stage, somewhat overlaps into the succeeding and preceding stages. This allows for flexibility in adjustment at each stage for optimum production of the entire system.

Primary Crusher: The Primary crusher’s main purpose is to reduce large fragments of blasted or natural rock down to a size suitable for handling by transfer equipment and the secondary stage crusher. Feed opening and product size ranges for the various models or Gyratory crushers are as follows:

a) Maximum Feed Opening — 1500MM to 750MM (5 ft. to 2½ ft.)

b) Recommended Minimum Product — 162MM(6½ in.)

Standard (Secondary) Cone Crusher (Refer to Fig. 1): The Standard Cone crusher is normally applied as a secondary crusher in a multi-stage crushing circuit. The small diameter feed distributor and the wide throat opening at the top of the liners enable the Standard Cone crusher to accommodate the larger feed produced by the Primary crusher.

Feed opening and product size ranges for the various models of the Standard Cone crusher are as follows:

a) Maximum Feed Opening — 625MM (25 In.)

b) Recommended Product Range — 100MM to 19MM (4 In. to ¾ In.)

Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers.

Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows:

a) Maximum Feed Opening — 250MM (10 In.)

b) Finished Product Range — 25MM to 10MM (1 In. to 3/8 In.)

The feed to the Short Head Cone crusher is normally screened prior to the crusher to remove the finished product sizes and to provide void space for the crushed particles produced in the cavity. Maximum production will be obtained when the crusher operates at or near full horsepower load continuously. To achieve this condition, plant design, feed distribution and the type of crushing cavity are factors which warrant considerations. The schematic arrangement shown in Figure 3 permits the crusher to operate with a controllable feed rate. The circuit shown in Figure 3 offers the optimum in crusher feed control and automation. The new feed is withdrawn from the bin directly to the crusher assuring a steady, controllable feed race. In a properly fed crushing cavity the material is distributed in a manner which utilizes the entire circumferential area of the receiving opening. It is equally important to have the finer gradations in the feed interspersed with the coarse feed.

Gyradisc (Quaternary) Stage (Refer to Fig. 4) The Gyradisc is applied as a fourth or final stage crusher. The Gyradisc normally handles feed of less than 50MM (1 to ½ In.).

Feed and product size ranges for the Gyradisc are as follows:

a) Feed Size — 75MM (3 In.) Maximum

b) Finished Product Range — 12MM (½ In. to 20)

Gyradisc crushers are specialized reduction machines. They are designed to economically produce large quantities of cubical product from stone, gravel, ores and non-metallic minerals. The feed for Gyradisc crushers usually has a topsize not larger than 75MM (3 In.) for the larger units and 30MM (1¼ In.) for the smaller size crushers.

Gyradisc crushers differ from conventional cone-type crushers because the comminution of material is achieved by a reduction process called Inter-Particle Comminution. The principle of reduction utilizes a combination of impact and attrition of a multi-layered mass of particles.

For proper operation, the crusher always operates with a choke level in the cavity. A controlled feed race permitting a constant power draw is required for an efficient circuit.

Through proper application of the Gyradisc crusher, mill feeds of 100 percent passing 3, 4, and 6 mesh are attainable. The crushing action of the Gyradisc crusher results in circulating loads of less than 50 percent of the new feed rate when closed circulating on 3 mesh, to 150 percent when closing the circuit on 6 mesh.

Screening

Reference is now drawn to the importance of screening in the success of the crushing circuit. It is not just the crushing of the ore but the extraction of the mill feed size that makes the circuit complete. A sufficient quantity of vibrating screens and full utilization of the total area they provide is an important factor in economically producing the mill feed size and tonnage established for the plant.

As a review of the screening phase in a plant, it should be asked if production is being sacrificed for screen surface life. Are the screens acting as chutes rather than mechanical separators?

Optimum performance of a vibrating screen is dependent upon selection of the proper screening surface. “Proper screening surface” might be interpreted differently by the screen manufactured, the surface supplier, and/or the operator; however, if approached from a practical standpoint there is one significant controlling factor to guide us in the selection of all screening surfaces. That is percentage of open area. With surface life being an important factor in the selection of the type of opening used, the rate of undersize extracted will be related to the percent of open area.

Charts were developed by vibrating screen manufacturers to be used as a guide in determining the size of screen required for a specific application and/or capacity capability of existing screens. Each manufacturer establishes capacity rating for specific operating conditions but use adjustment factors to compensate for variations in these operating conditions.

Differences in the amount of oversize, undersize, half size, etc. are the common adjustments to suit actual operating conditions. Overlooked and often forgotten by many of us is the effect of the screening surface on screen performance. The screen manufacturers basic capacity rating is normally established for square opening woven wire screen cloth having a specific percent of open area. In addition, the supporting beneath is designed to provide maximum open area for woven wire cloth.

A common adjustment factor applied by screen manufacturers for changes in surface open area is as follows:

O.A. Factor = % Open Area of Surface Used/% Open Area Indicated in Manufacturers Capacity Chart

This formula was originally intended to apply and be meaningful when substituting wire cloth with a smaller or larger wire diameter. There may be additional obstruction of open area when mounting perforated plate, rubber, polyurethane surfaces on supports designed for wire cloth. This is not compensated for in the above formula. Of course, there is also the danger of structural instability when mounting the heavier surfaces on supports designed for wire cloth.

Installing heavier surfaces may also cause a reduction in screen throw and unless it is compensated for the reduced action will result in very erratic and inefficient separations regardless of the open area.

There are already so many factors to deal with in every processing plant. Moisture, particle shape, uneven feed distribution, surge feeding, and excessive feed rates all of which are detrimental to maintaining high screening efficiency. Conditions are more unfavorable when a decrease in open area is added to this list.

Another factor enters the picture in recent years and that is rubber and polyurethane type surfaces are not always used just to extend the life but tend to dampen noise when compared to surfaces of steel construction. Often changes in surface specifications are made without a thorough evaluation of the consequences. There is often need to compromise by weighing the advantages against disadvantages of each type of surface with the major or final consideration being the actual cost per ton of mill feed extracted from the circuit. The table showing the capacity adjustment factor is useful in calculating screen are requirements when alternate surfaces are being considered.

This practice has been followed successfully in several Minnesota taconite installation. The secondary crusher product is screened and conveyed to bins ahead of the tertiary crushers. The tertiary crushers operate in either open or closed circuit with a variety of arrangements available in positioning the tertiary screens. The screens can be placed above or below the tertiary crushers or in a separate screen house. With the advent of automatic crusher feed control systems it becomes important to reduce the reaction time between the feed control mechanism, such as a vibrating or belt feeder, and the crusher, to a minimum.

Where secondary and tertiary crushers are stacked with a scalping screen between the two, surge and feed control for the tertiary crusher becomes more difficult. This results in lower efficiency from a power utilization standpoint. The initial cost of construction for this type of plant is usually lower than the aforementioned horizontal layout.

The positioning of the secondary and tertiary crushers depends on a variety of factors including terrain, moisture level in the ore, storage capacity both before and after fine crushing and benefication steps.

Usually the fine crushing plant is located some distance from the primary with an intermediate ore storage facility between. The operation of the fine crushing plant is independent, to a large degree, of the performance of the primary crusher.

A great deal of thought has been given to the problem of attaining maximum efficiency in this type of operation. Efficiency is measured by the work of reduction on the ore per unit of time and by percent running time. The work of reduction is represented by tonnage of throughput and degree of size reduction.

To attain the maximum work of reduction, each crusher must be kept at full capacity. The capacity may be limited volumetrically in the case of softer ores, or by the horsepower that can safely be applied to the crusher in the case of harder ores.