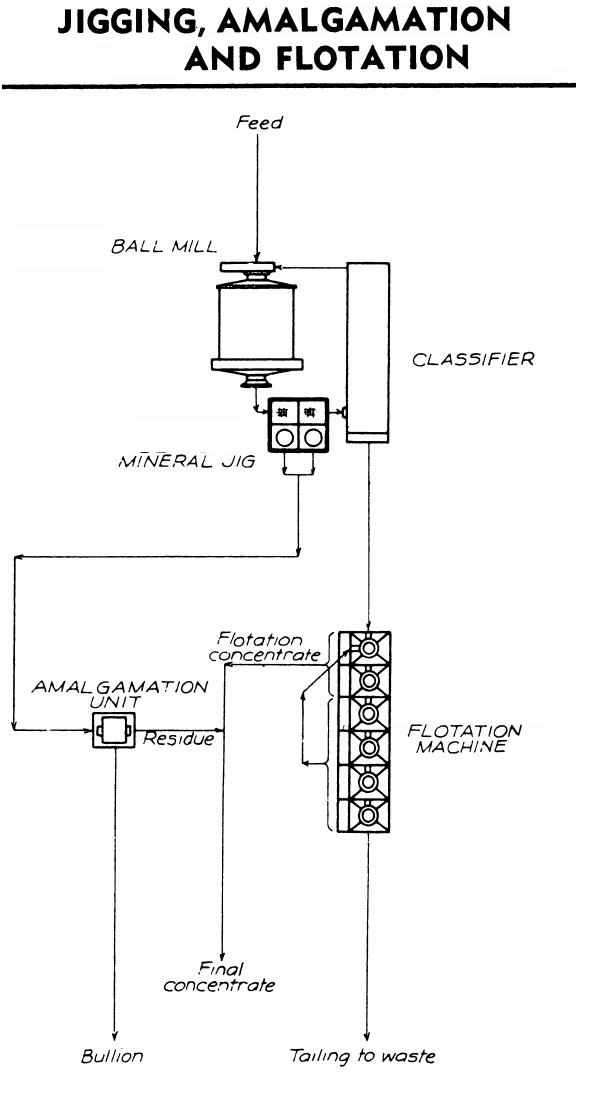

CIRCUIT PROCESS FLOWSHEET DESCRIPTION: A Gold Jig ahead of the flotation circuit with or without amalgamation of the Jig concentrates.

ORE TREATED: Most gold ores where flotation is used for final recovery. Lead or lead-silver ores containing coarse lead sulphides or lead oxide minerals, also pyritic ores containing gold and silver.

ADVANTAGES: Although most gold ores are not classed as “free milling”, it is found in many cases that a reasonable percentage of the gold is freed in fine grinding for flotation. This gold may be recovered by the Jig in the ball mill-classifier circuit, preventing its recirculation and overgrinding which may results in tailing losses BUT ARE recovered by froth flotation. A small bulk of high grade concentrate is obtained which can be put in bullion form by “forced” amalgamation. The overall net recovery for the plant ‘is improved through lower tailing losses, lower freight and treatment charges on the lower grade flotation concentrates, and through higher returns on bullion sold to the mint.

When treating lead or other sulphide ores where the minerals are coarse, the Mineral Jig recovers a coarse concentrate and removes it from the ball mill-classifier circuit before sliming and subsequent probable tailing loss.

PROCESSING COMMENTS: In addition to the direct savings outlined, the uncertainty of sampling and assaying the flotation concentrates is avoided as “metallics’ have been removed in the Jig. In producing a coarse sulphide concentrate for shipment, the Mineral Jig is replacing tables in the ball mill-classifier circuit.