Table of Contents

Very little is documented about Gold Room Security due to the sensitivity of people around it. At the same time, when establishing a new operation it is useful to have a standard security starting point on which to address the issues with directly related to gold room security design fundamentals. This paper will provide guidelines and a ‘prompt’ for the issues to be considered when establishing a new operation. Gold mining invites the inherent problems of vulnerability, threats and countermeasures for the security of gold products. Due to the errors in metallurgical accounting and grade control issues, gold theft may be undetected for some time. Generally, stealing starts in a small way leading to larger theft and at some scale the theft is detected.

by D. Connelly

Historically, the greatest threat to gold security is from internal staff. Typically, when gold is stolen by a person in a position of trust, they have had no previous record of dishonesty. Personal circumstances may change altering ethical values and moral judgement and this is borne out by anecdotal evidence. Sadly, the old proverb, ‘opportunity makes the thief’ is very true. Recently, external personnel have conspired to steal gold, but this is usually by forcible entry or use of staff as hostages.

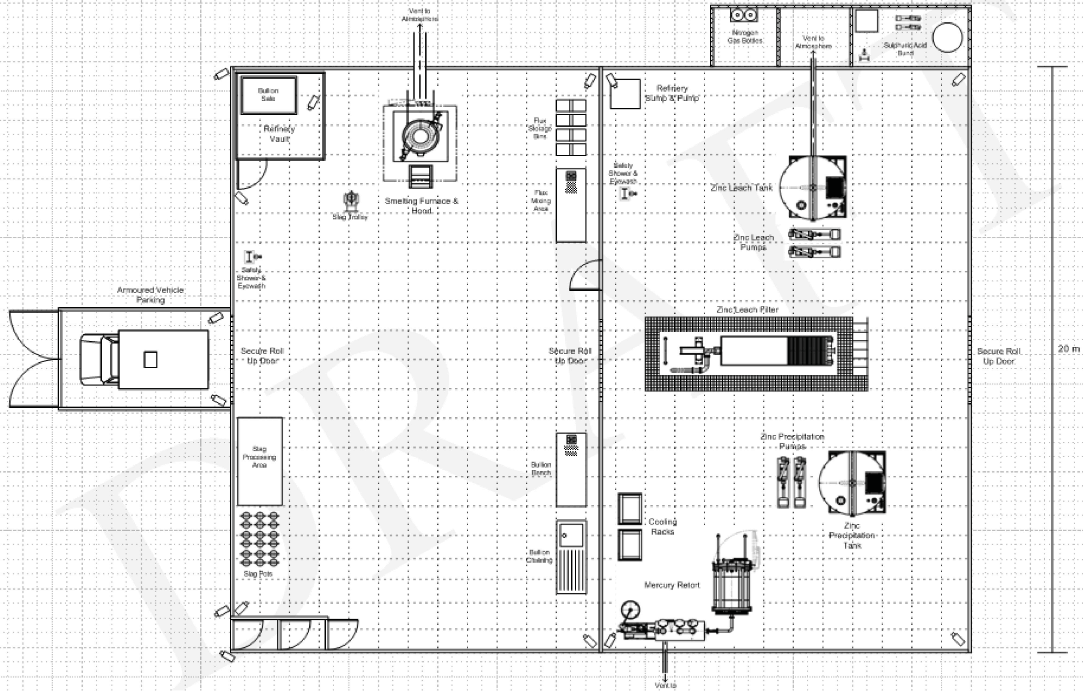

Gold is a high value asset that can be stolen and measures must be taken to minimise the possibility of such occurrences. Recognising that the gold room is vulnerable is the first step in developing a strategy aimed at reducing the risk. Safety countermeasures should be in place where patterns for gold pick-up are not well established. Very few people should be aware of gold pours or pickups. The impact of any loss can be material to the profitability of the operation. Security arrangements in the construction should allow for personnel entry via a double locked single entry arrangement using card passes. There should be a larger door for entry by armoured vehicles or forklifts and this should also be via a double locked single entry system. The design layout here shows a security office and screening facility should it be deemed that these are necessary. There is also a first aid room, which could be utilised for the whole of the plant site.

Gold Bullion Room Records

A permanent hardcover book should be maintained in the gold room in a safe place. The book should record the date, batch number, weights and conversions for all materials. All movements of gold products into and out of the safe should be recorded. As a security measure, conversion statistics are very useful for establishing historical records. Records of all material entering and leaving the gold room are required.

Minimum Security Standards Checklist

Develop written site security procedures including bullion shipment,

set up gold room record books,

include CCTV, 90 day hard disk recorder, card access and typical protocols,

get the Gold Squad to review the site security,

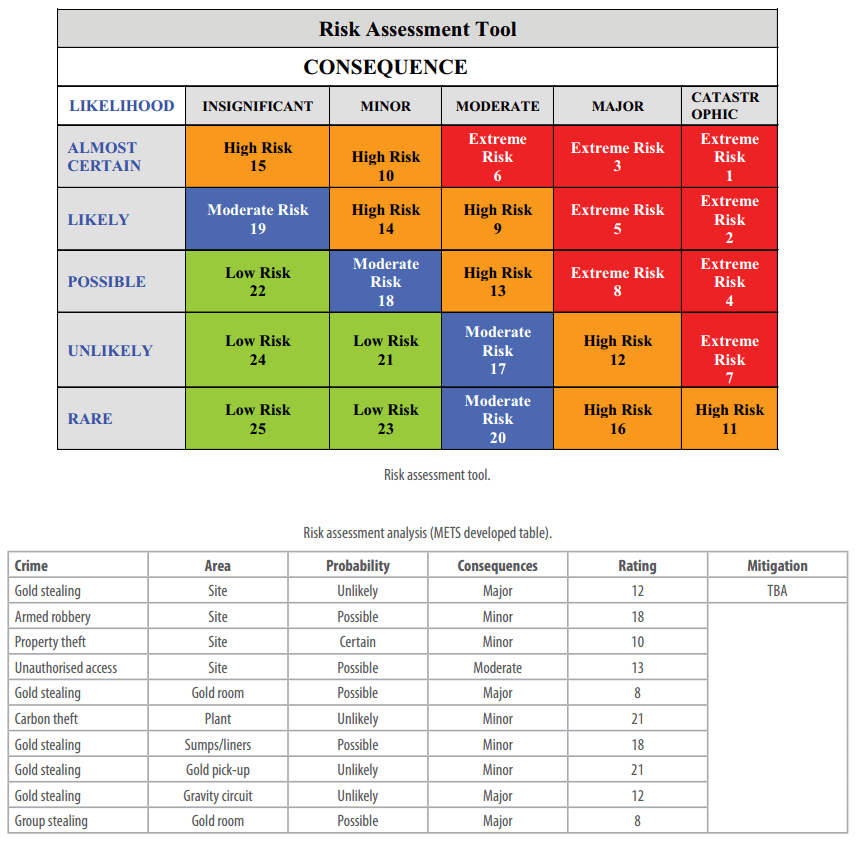

undertake internal risk assessment,

use of metallurgical accounting to detect discrepancies,

development of emergency procedures,

send a sample of dore bullion for fingerprinting, and

include 24/7 external monitoring.

At strategic points, such as the office, vault, etc., electrical alarm switches should be located. In the event of an unusual circumstance, a switch can be actuated to sound a general alarm to the plant security office and in some cases directly to local law enforcement offices.

The refinery fenced area should have sufficient room for ample flux and spare parts storage, change rooms, slag treatment equipment, etc. , that once the refinery crew enters the enclosure, they can remain there until the end of the shift. Some refineries can be adequately operated by one man and a helper; larger operations, of course, require more men. It is advisable to have on duty within the refinery an extra high level staff member as security supervisor who reports directly to management. This added cost affords protection at a time when gold is at its highest price ever with “Highgrading” becoming a very real temptation. Accountability for all gold samples in and out of the refinery should be accurately maintained and double checked. The amount of gold in assay samples can vary from a few hundred to over 1,000 gold ounces per year. This can be adequately handled by the staff member refinery supervisor. Past records of refinery personnel should be carefully checked by local law enforcement agencies. The “honor system” of trusting employees should not replace tight security enforced by management. Transportation of the bullion production to shipment points should be in the hands and under guard of trained professional law officers and not mine employees.

Metallurgical Accounting

Metallurgical accounting must be at a high standard and a monthly reconciliation should be undertaken. Procedures should be documented and discrepancies reported. A strip summary should be used to maintain a check on gold room security and efficiency. Over a week the gold stripped should equal the fine gold poured which serves the dual purpose of maintaining good security and providing the ability to predict the gold pour before the pour date based on strip assays. If this balance cannot be established then the following possible causes need to be investigated.

Weightometer calibration issues, gold in circuit (GIC) errors, sampling and assay issues and as a last cause possible theft. Bullion shipment records should be kept. Metallurgical accounting will not detect small quantities of theft, but will highlight larger theft if the procedures are of a high standard and monthly reconciliation is undertaken.

Gold Room Operations

- Occupational health is paramount, and adequate fume extraction and shower facilities must be provided.

- Gravity flow is used wherever possible with electrowinning cells located on a mezzanine floor.

- All hoppers and wash vessels must encourage flow, because cell mud is a high-SG material.

- Operator access to key control points such as electrowinning rectifiers must be maintained external to the gold room for security.

- Adequate wash-down and silt trap facilities must be provided.

- The building must be secure.

Gold Room Security

The level of security attached to a facility is site specific and is driven by a number of considerations:

- The economic development of the country.

- The level of institutionalized gold theft.

- Client preference.

- At the lowest level, the gold-room security will include motion sensors, closed-circuit television (CCTV) cameras, and a locked door.

- At the highest level it will include all the above together with a separate perimeter fence with CCTV, in situ guards, and body searches.

Minimum Industry Gold Room Security Standards by D. Connelly

Excerpt Posted with author’s permission. Original and full paper at https://www.ausimm.com.au/publications/epublication.aspx?ID=6524

Other Goldroom Duties

- Loading of cathodes.

- Sweeping/hosing of gold plant area.

- Maintaining a stock of bullion boxes.

- Carrying out repairs to the barring furnace.

- Re-stocking of fluxes.

- Re-stocking of reagents.

- Reaming out of the regeneration kiln heat tubes.

- Cleaning of the heat exchanger plates.

- Checking of the thermocal level in the expansion tank and topping up when necessary

- Cleaning of the inline screens before each of the gold plant pumps.

- Cleaning out of the electrowinning cell, eluate tank and potable water tank when required.

- Cleaning of screens in both columns and the quench tank

- Cleaning out the sump pump pits.

- Regular hosing down of the spirals.

- End of period stocktakes.

- Monitoring of the condition of all plant and seeing that the required maintenance is carried out.

More Security

It does not matter how honest employees are, if gold is deemed to be missing, ALL persons will be potential suspects. Avoid the possibility of this by observing the following rules.

- Keep the goldroom doors, the strongroom and safe doors locked.

- Do not leave any cathode cake, gravity concentrate or smelted products unattended. Lock them up in the strongroom when they are not due for immediate handling.

- Maintain very precise records of the movement of all cake, gravity gold and smelted products.

- Maintain very precise records of stripping and in particular the intensive cyanidation operations. With the introduction of intensive cyanidation, daily accountability is difficult. In most instances it will not be possible to relate input to output, i.e. head grades with final product, until completion of smelting every Tuesday; under the past acid digestion system there was a degree of daily accountability.

- Good sampling is essential! All intensive cyanidation leach and rinse batches must be measured and assayed. Loaded and barren carbon samples must be taken at regular intervals during transfers. Good sampling helps to ensure accurate accounting and accurate accounting provides a back up if the ‘books don’t balance.’

- No gold should leave the goldroom without being recorded in the “gold movement’ record book; the entry duly witnessed. No gold products should be stored outside of the goldroom,

- If returning to the goldroom after hours, make sure that the shift foreman is aware of your presence, and preferably note the reason for and time of your visit in the shift log book.

- Do not allow any unauthorised person to enter the goldroom. All visitors should be entered in the visitors book.

- Do not leave your goldroom keys lying around – or allow others to use them. (Ninety nine percent of the people around this plant would be quite capable of copying them.)

- When despatching bullion of a Wednesday morning, keep the goldroom doors locked until such time as the bars have been signed out and all of the necessary paperwork associated with their despatch, completed. Only then should the loaded bullion boxes be taken out to the vehicle and the security guard should be standing by the vehicle when this is done.

- Maintain radio contact with the gold movement vehicle until the gold plane has taken off.

Safety

Reagents and Fluxes

This gold plant uses an assortment of reagents and fluxes most of which possess some or all of the following characteristics:-

- Highly corrosive.

- Highly poisonous

- Inflammable – if combined with some other reagents or materials.

- Explosive – when combined with some other reagents or substances.

All employees should read the information sheets at the end of this section relating to individual reagents and fluxes. They should take particular note of the appropriate first aid attention necessary in the case of adverse exposure.

Hand Safety and Handling

Prevention is better than cure! Wear appropriate safety gear when handling liquid reagents or fluxes. When handling liquid reagents, wear rubber gloves and a full face mask with appropriate cartridge filter. For most goldroom reagents a filter suitable for organic vapours is appropriate but when handling cyanide a cartridge specifically for use in cyanide contaminated areas must be used.

When mixing fluxes, rubber gloves, safety glasses and disposable face mask must be used. Even the most harmless of the fluxes, silica flour, (not included in the information sheets as it does not possess any of the characteristics detailed in section 9.3a) can have serious long term respiratory effects if inhaled.

Extreme care should be taken when drying concentrate or cake. The fumes given off can at times be quite toxic or irritating if inhaled. When in doubt wear a mask! Or hold your breath.

General Safety

- Normal safety rules apply within the goldroom surrounds. Safety boots must be worn at all times and when working outside of the actual goldroom, a safety helmet must be worn. Safety glasses must be worn in the proximity of the acid and elution columns when they are operating.

- Good housekeeping is essential at all times. Do not leave things lying on the floor and clean up all spills immediately after they occur.

- When working on any piece of equipment make sure that it has been appropriately isolated and tagged out at the main control panel

- If inspecting “in column screens’ or( changing heat exchanger plates, ensure that all necessary manual valves are closed and that any associated pumps are isolated and tagged out.

- When working near the furnace on smelting days, full protective clothing must be worn.

- Always wear gloves when handling slag. Even when cold it can inflict harm as it may be very sharp.

Gold Ore Processing: Project Development and Operations[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]