The third type of classification used in mining is the Hydrocyclone, commonly called a Cyclone. Unlike the others it has no moving parts and is worked in conjunction of another piece of equipment, a pump. To understand the Hydrocyclone Working Principle we must first know its components. Beginning at the top, there is the OVERFLOW DISCHARGE.

The third type of classification used in mining is the Hydrocyclone, commonly called a Cyclone. Unlike the others it has no moving parts and is worked in conjunction of another piece of equipment, a pump. To understand the Hydrocyclone Working Principle we must first know its components. Beginning at the top, there is the OVERFLOW DISCHARGE.

Unlike the rake and spiral classifiers, the overflow of the cyclone is the exit point for the fine material instead of the other way around as it is in the case of the other two. Extending from the overflow discharge into the body, which is the feed entry point of the cyclone, is the VORTEX FINDER.

This is simply a length of pipe, its purpose is to provide a point of separation between the coarse and fine material. A better explanation will be possible once we begin explaining how it works. Next in our list of cyclones components is the UPPER and LOWER CONE, not all hydrocyclones have this section divided into two cones. Some are designed this way do to make repairs easier, and to isolate wear points, Their function is to help create a VORTEX.

This is done by guiding the slurry to the underflow at the same time presenting a smooth surface that will not restrict the generation of the CENTRIFUGAL FORCE that makes classification possible. Connected to the lower cone is the APEX. The apex is the discharge point of the cyclone, this discharge is referred to as the UNDERFLOW. The material that exits at this point will be the material that requires further grinding. The last part of the cyclone is the cyclone SKIRT. It is there only to limit spillage and splashing it isn’t important to the operation of the cyclone.

I would suppose you are asking yourself, why and how does this piece of equipment separate the different sizes of rock? To answer that, we have to get into the operational theory of the cyclone. To start with, the slurry is directed into the cyclone along the wall of the body. Due to the ore being pumped, the slurry has VELOCITY. It is this velocity and point of entry helps in creating a spiral path around the outside of the body, the upper and the lower cone.

The entrance to the cyclone was designed this way to allow the incoming feed to help generate and not interfere with the spiral path that the ore must take inside the cyclone. The centrifugal force (the central Hydrocyclone Working Principle) that is generated by this spin, forces the “bigger particles outwards towards the wall of the cyclone. If you were able to do a cross section of a cyclone while it is operating, you could see that the ground rock will become finer the closer that you get to the centre of the cyclone.

It is the APEX at the bottom of the cyclone that is the most responsible for creating the spin required for the CENTRIFUGAL SIZING of the slurry.

The centre of this spiral is called the VORTEX. The purpose of the apex is to cause internal pressure for the cyclone and to create a vortex that extends all of the way to the top of the cyclone.

In all hydrocyclones there are two outlets, one for the coarse material, this is the APEX, and the other for the fine material, which is the VORTEX FINDER. The purpose of the Vortex finder is to separate the fine material from the coarse as it spirals around the vortex. The WIDTH of the Vortex finder will determine how far into the coarser material the separation point will be.

The Volume of slurry that is being fed into the cyclone must not exceed the capacity of these two outlets that allow it to escape. The size of the apex and the vortex finder is crucial. If the apex of the cyclone, like the size of the drain in your sink, is made smaller it won’t allow as much slurry out of the underflow of the cyclone. This will cause the vortex to be smaller the internal volume of the slurry inside the cyclone will be greater and the amount of material that the vortex finder separates to become part of the overflow will be increased.

As it is the DISTANCE across the vortex finder that determines where in the vortex the ore flow is separated at, the SIZE OE THE APEX will determine the degree of classification that the ore will be subjected to.

The size of the apex in relationship with the volume of slurry that is being fed to the cyclone, will create and maintain the PRESSURE NECESSARY to force the fine material out of the cyclone. The greater the pressure the greater the volume of overflow. To increase the overflow requires either a higher volume fed to the cyclone or a smaller underflow discharge opening. As the pressure in the cyclone climbs the amount of coarser material in the overflow increases. The reason that this pressure is generated is because the volume of the feed is greater than apex discharge capacity. The pressure is generated as the volume of slurry is built up over the apex.

These three factors then become your operating Variables when dealing with cyclones, APEX SIZE, the SIZE of the VORTEX FINDER, and the VOLUME of the feed. The CYCLONE PRESSURE becomes a control indicator for the adjustment of the apex size and the volume of the feed. The vortex finder is a FIXED VARIABLE, meaning that it can be changed to affect the sizing of the overflow, but not as a normal operating practice. The cyclone must be removed from service and taken apart to make that adjustment.

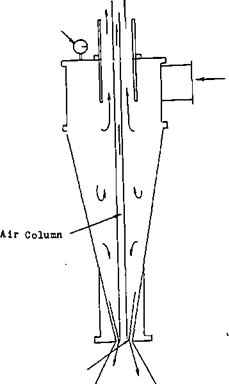

If the variables become unbalanced to the point where the pressure is too high, the cyclone will overload. What this means is that when a vortex is generated, an air column is formed in the center of the vortex. If this air column collapses, the velocity of the spiral will decrease far enough to lose the centrifugal force that causes the ore to classify. As the internal pressure of the cyclone represents the volume of slurry that is in the cyclone it only follows that the reason that the air column should collapse is that there isn’t room left in the cyclone for the air.

If the variables become unbalanced in the opposite extreme then there won’t be enough pressure to cause an overflow. Either the volume will be too low or the apex size too large. This will result in all of the feed being discharged out of the underflow.

By what you have just learned it is apparent that to maintain an even pressure on the cyclone is very important. If the cyclone is dependent on pressure to function effectively then a constant pressure would ensure positive control over the classification of the ore. This means the pump that feeds the hydrocyclone is very important to the effective working of that hydrocyclone.

To understand how pumps work we will have to leave their relationship to cyclones until we have discussed their components and functions. Once we have finished discussing the pumps by themselves, we will come back to this relationship and explain the other variables that effect the performance of these two machines.