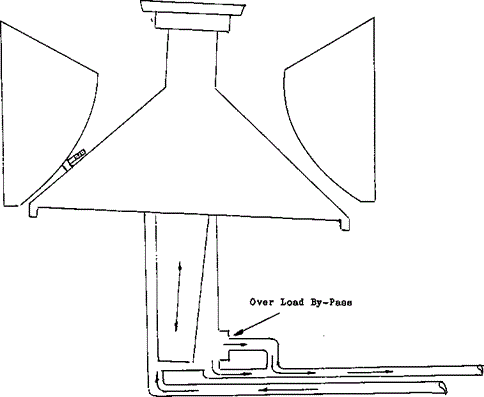

As you can imagine the forces that are put onto the main frame and body of a cone crusher are fairly great. So what happens if something that can’t be crushed, like a steel bolt, gets into the crusher? Instead of damaging itself the crusher has a built in safety device. The tramp steel release. This will take the form of either spring releases as in the diagram, or within the mantle adjustment mechanism on some types of crushers.

With the spring release they allow a certain amount of give between the mantle and the bowl liner. If stray steel should get into the cone crusher, the work load will exceed the pre-set strength of the springs. The frame and the bowl liner will lift with mantle as it goes through the crushing portion of its cycle. Once the mantle begins to open again it will let the steel pass through.

With other types of crushers it is the mantle that moves instead of the frame.

Cone Crusher HydrosetThe Cone Crusher HYDROSET, which is a hydraulic method of adjusting the size that the crushers will crush to, has a release mechanism that allows the mantle to drop should the work load be exceeded.

In both these crushers should the steel be larger than the release will handle, the crusher will be jammed. If this should happen, the only remedy is to dig the crusher out by hand and burn the offending metal away with a special oxygen- acetylene cutting torch.

Each Omnicone features dual function hydraulic cylinders that provide overload protection and a safe and fast way to clear a jammed cavity. Should the crusher become plugged, the operator merely pushes levers on the remote control console to clear the cavity.

Each Omnicone features dual function hydraulic cylinders that provide overload protection and a safe and fast way to clear a jammed cavity. Should the crusher become plugged, the operator merely pushes levers on the remote control console to clear the cavity.

The cylinders are double acting. They supply the force to hold the adjustment ring securely to the frame and also act as clearing jacks by raising the adjustment ring, bowl and hopper assembly.

![]()