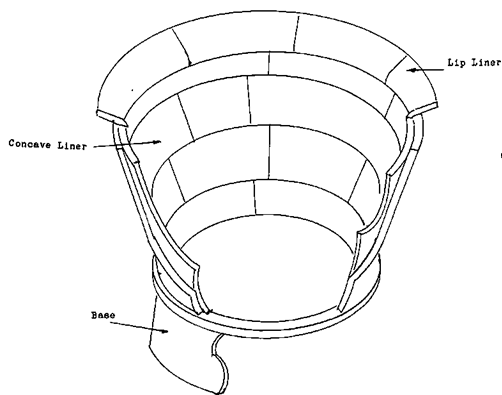

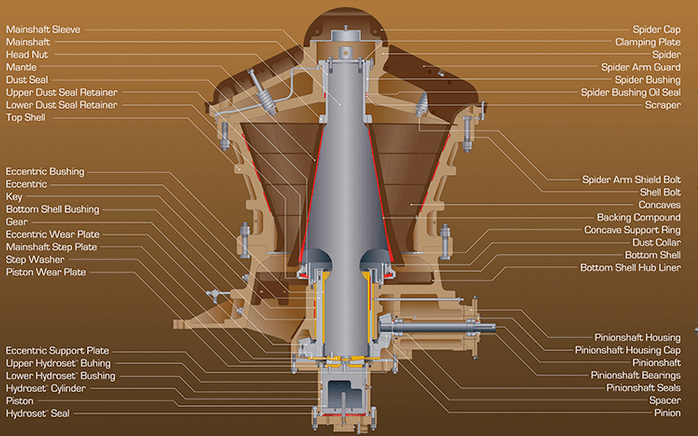

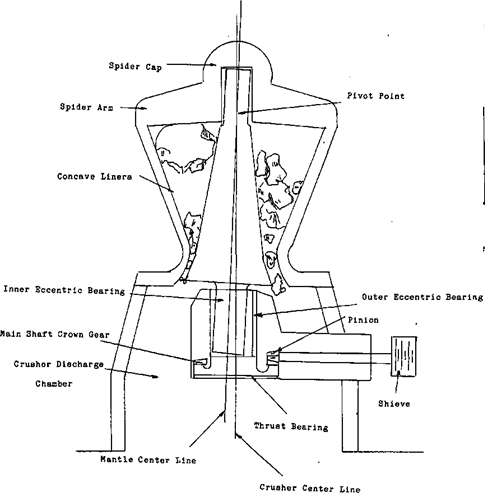

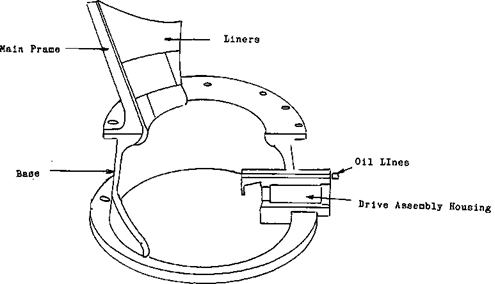

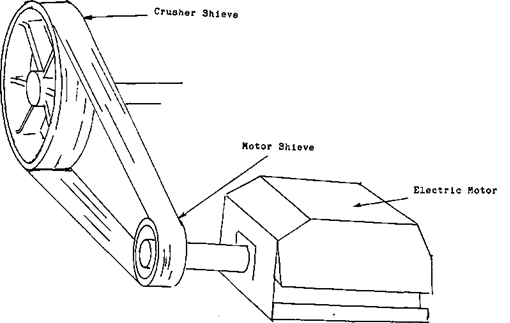

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system.

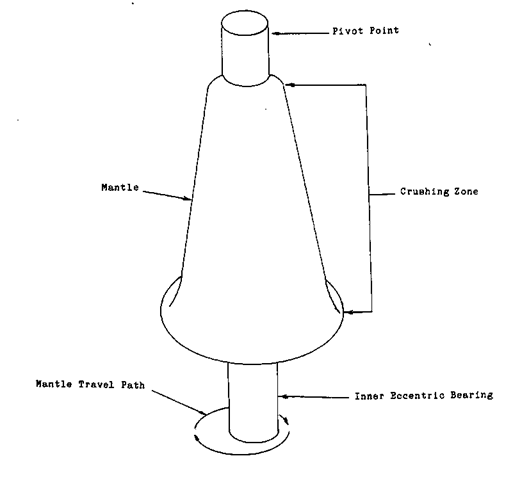

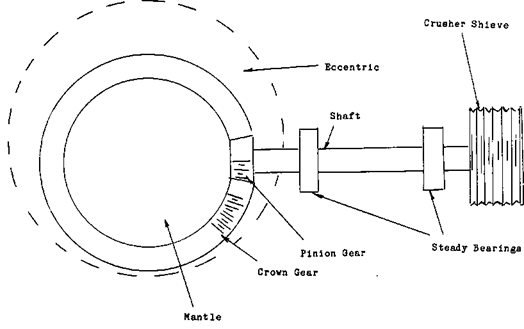

It is this eccentric bushing and bearing that gives the crusher its crushing action. To understand how it works it might help to learn the dictionary meaning of the word eccentric which is:

- Differing conspicuously in behaviour, appearance, or opinions.

- Not situated in the centre as an axis. Deviating from a perfect circle: said chiefly of an elliptical orbit.

That means that in this case the centre of the MANTLE is off set from the middle of the CROWN GEAR. As the crown gear is turned the mantle is revolved in a circle. To complete the crushing action the centre of the top of the mantle is brought back to the centre of the crown gear and is pivoted in the SPIDER BEARING under the SPIDER ARM CAP. As you can see this causes the space between the CONCAVE LINERS and the MANTLE to open and close as the mantle revolves. Because the top of the mantle is pivoted the action at the top of the mantle is very little. The farther down the mantle you go the greater the crushing action becomes and the MANTLE to open and close as the mantle revolves. Because the top of the mantle is pivoted the action at the top of the mantle is very little. The farther down the mantle you go the greater the crushing action becomes.

https://www.911metallurgist.com/gyratory-crusher