Table of Contents

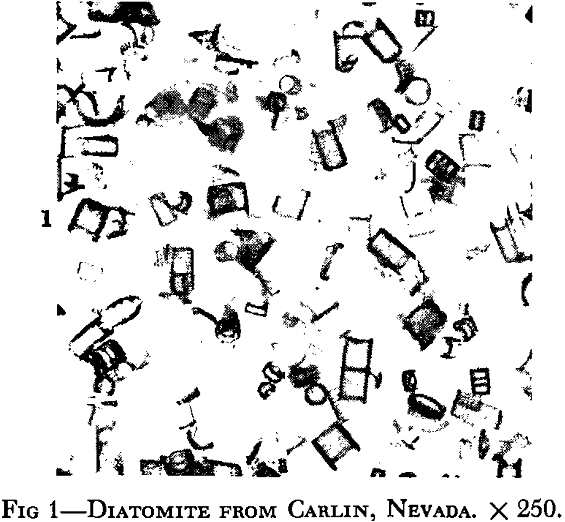

Diatomite is a hydrous or opaline form of silica, commonly known as diatomaceous earth, diatomaceous silica or kieselguhr. The term “infusorial earth” has lost its original meaning and today is incorrect in view of the distinctions between diatoms and infusoria. Various locality and variety names are obsolete but some retain local significance. Moler and Celite are trade names that have become associated with diatomite products from certain deposits in Denmark and near Lompoc, California.

Composition

Diatomite is essentially silica with some combined water (2 to 10 pct). Frequently it contains organic matter (from traces up to over 30 pct) and varying amounts of inorganic impurities such as sand, cryptocrystalline silica, clay, volcanic ash, calcium carbonate, magnesia and soluble salts. In the natural or crude state, diatomite contains from 10 to 65 pct or more of free water. Table 1 gives analyses of several diatomites from deposits of different types.

Properties

Pure varieties, either massive or stratified, are friable and porous, of low apparent density, and somewhat chalklike in appearance. Varieties containing organic matter vary from sedimentary oozes to peatlike materials. Impure varieties may be more or less claylike, sandy, calcareous or cherty. Compacted types approach porcellanite and silicified shales.

Color—white, cream, gray, tan, brown, greenish to nearly black.

Hardness—light-weight varieties appear 1 to 1.5 because of porosity, but microscopic particles are 4.5 to 6.5.

Specific Gravity—1.9 to 2.35.

Apparent Density—dry block form, 20 to 40 lb per cu ft; dry powder, 5 to 16 lb per cu ft.

Crystal System—generally amorphous (isotropic by X-ray diffraction) but frequently showing faint cristobalite pattern.

Melting Point—1400° to 1650°C.

Streak—white.

Origin and Mode of Occurrence

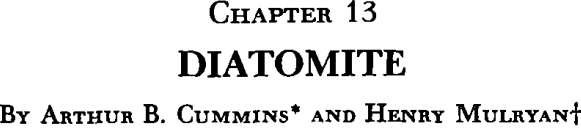

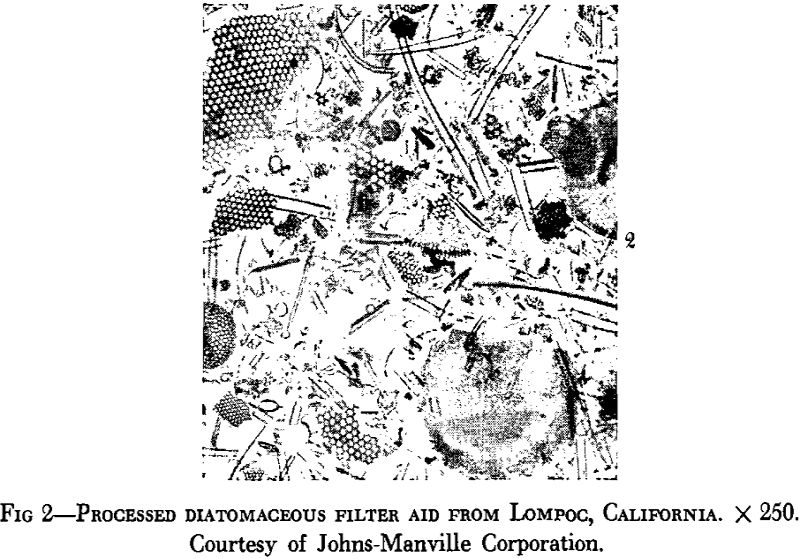

Diatomite is of organic origin, consisting of the fossil remains of microscopic aquatic plants known as diatoms, of the order Bacillaria. These minute organisms are distributed widely in nature, growing wherever conditions of light, moisture and food supply are favorable. Each tiny plant is enclosed in a siliceous envelope and when the organism dies it sinks to the bottom of the water, where the organic mat-

ter is more or less decomposed, thus forming a deposit of the siliceous valves. The origin of diatomaceous peat deposits and the accumulation of diatomaceous residues has been considered by Conger.

Diatoms grew in great profusion during various geological periods, particularly the Miocene, and the most important economic workings today are in the fossil deposits of that period. Some deposits, however, are recent and others are in the course of formation. No large economic deposits are of earlier age than the Tertiary. Deposits are of both marine and fresh-water origin; in geologic age they range from the Cretaceous to the Recent.

Political and Commercial Control, Production and Consumption

Most requirements for diatomite have been supplied by large individual companies or by trade organizations. Thus, in the United States, the Celite Company and the Johns-Manville Corporation pioneered the industry and continue to supply the greater tonnage for domestic consumption and also considerable tonnages for export shipments, particularly for filtration and filler uses. The Great Lakes Carbon Co. and the Eagle-Picher Co. operate western deposits. Production in Canada has decreased since 1935.

In Germany the Vereinigte Deutsche Kieselguhrwerke G.m.b.H., Hamburg, has largely controlled the production and marketing of kieselguhr. It represents a trade organization correlating the production of numerous works, principally in the Luneburger Heide district.

In France is La Societe de Silices Fossiles de France, at Paris, which controls much of the Algerian diatomite. In Denmark, Moler Products, Ltd. and Mors-Moler largely control the industry. In Soviet Russia production and shipping is controlled by the Government. Private companies operate in North Ireland, Spain, Australia, Italy, Japan, and other countries.

In the United States and Canada many minor companies and organizations have operated different deposits at different times. While most of these have been of temporary existence, with many ownership changes, some of the smaller producers have operated for many years and have been successful in specialties. A feature of the diatomite industry in the United States has been a rather high degree of technical proficiency in product and process improvement, development of new uses and in maintenance of technical service to the consuming industries.

In North America, and to some extent elsewhere, the trade’ has come to expect distinct uniformity of grade and high-quality standards in diatomaceous products, except where they are used locally or are utilized in the cheaper fields of building materials, ceramic insulations and concrete. The present developed resources in the United States still appear adequate to meet all requirements for many years to come.

Prospecting, Exploration and Mining

In the dry, compact, stratified deposits, samples may be obtained from the surface outcrops and examined microscopically, physically or chemically. The purer beds are thus determined. Diatomite lends itself to core drilling readily arid in some places prospecting is done in this manner. In others, trenches, tunnels, and vertical shafts of narrow cross sections are used to examine the diatomite away from surface conditions of alteration and leaching. These are more satisfactory methods of examination because of the ease with which the diatomite can be excavated. The openings permit a careful examination of the appearance of the material, its stratification, compactness, and inclination of beds. In the wet bog, lake, or swamp deposits, auger drills are often used, so that one foot of material can be brought up at a time. For underwater sampling, a casing is driven into the mud and boring is done inside the pipe. Tonnages are based on the amount of dry material in a cubic foot of the earth.

Tests and Specifications

Crude diatomite is evaluated on the following properties: freedom from impurities (sand, volcanic ash, crystalline silica, organic matter, clay, lime, soluble salts, etc.); microscopic structure (types of diatom forms and their condition, whole or broken, and relative proportions of different diatom forms); presence or absence of exceedingly fine particles; apparent or bulk density; friability (behavior on milling); color; opaline silica content.

Uses

The uses of diatomaceous silica in order of importance have been estimated as follows: filtration 50 pct, insulation 25 pct, fillers admixtures and miscellaneous 25 pct. The more important uses are:

Filtration—Diatomite is used in filtering raw cane sugar and in refining; in beet-sugar manufacture, and with molasses, corn sugar and glucose, maple sirup, beer and wort, wines, distilled spirits and liquors, fruit juices and beverages (grape, prune, cider, citrus), fruit pulps, pectin, malt products and extracts, water (military, municipal, boiler-feed and other industrial waters, swimming pools, etc.), dry cleaning, mineral oils and petroleum products, vegetable oils, animal oils and fats, liquid soaps, gelatin, glue and adhesives, chemical solutions, electroplating solutions, salts and salines, titanium pigments, metallurgical slimes and solutions, cutting oil emulsions, sewage, gas purification, pyroxylin and cellulose acetate, varnishes and lacquers, trade wastes and effluents, rigid filters (bacterial, etc.), porous diaphragms, separators, etc., flavoring extracts, vinegar, hydrogenated oils, alginates, starch pastes, sizing, etc., dyestuffs, used crankcase oils, analytical and laboratory uses, serums and antitoxins, perfumes, extracts, pharmaceuticals and cosmetics, penicillin, streptomycin, vitamin extracts, etcetera.