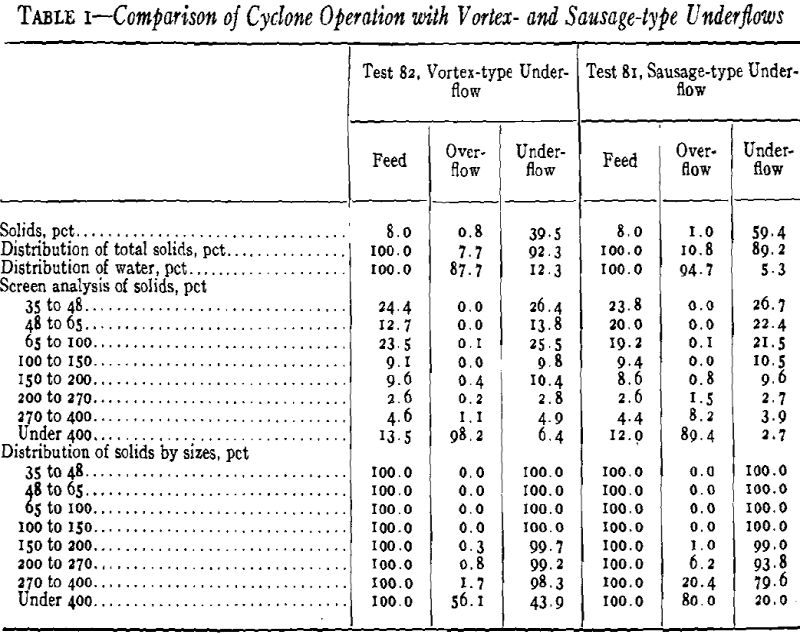

Table of Contents

With the exception of pneumatic processes and a few special bencficiation methods of comparatively limited application, all mechanical coal-cleaning and mineral-dressing processes involve the admixture of solid particles with a liquid, generally water. Upon completion of the beneficiation process the solids must be reclaimed from the water. With coarse particles separation of solids from water is accomplished readily by the simple expedient of screening, but recovery of fine solids presents a much more difficult problem. Thickening and dewatering are practiced so generally, both within the mineral industry and elsewhere, that they have been the subject of study through the years and a number of processes for making the solid-liquid separation have been developed. Dorr-type thickeners have been standard equipment for many years, and more recently driers employing centrifugal force have gained in popularity.

Object and Scope of Investigation

Although the cyclone thickener has been dealt with in three reports by Driessen, its use as a thickener was not the principal subject of any of these reports and therefore neither the cyclone itself nor its operation was described completely. The design of the cyclone was described only in a very general way, only limited operating results were given, and virtually nothing was disclosed about the influence of the various possible operating variables. Moreover, the Netherlanders apparently had employed the cyclone exclusively for thickening loess and had not employed it on coal slurries. One English colliery has used a cyclone to thicken coal slurry, and as it appeared that the Netherlands-type cyclone might have wide application as a thickener for coal slurries in this country, the Bureau of Mines launched an investigation to provide information about construction and operation. The investigation has been in progress for about six months and it has become apparent that considerable time will be required to study completely all aspects of cyclone design and operation. Therefore, since the results obtained thus far have been so promising, it was considered advisable to publish them now for the benefit of the coal industry rather than to await completion of the investigation.

Description of Equipment and Testing Procedure

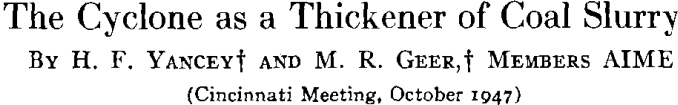

The conical section, which is the heart of the cyclone, is 5 in. max diam, 1 in. min diam, and 11.3-in. high; the total inclosed angle of the cone is 20°. Immediately above the conical section is a cylindrical ring 1 3/8 in. high and 5 in. in diam, through which the feed tube enters the cyclone. The feed tube, which tapers from 1½-in. to 11/16-in. diam in a length of 7½ in., enters the cyclone on a tangent with the cylindrical ring and is inclined downward at an angle of 5° from the horizontal. Surmounting the cylindrical ring is a removable orifice plate fitted with a tube extending down into the cyclone. The chamber above the orifice plate serves to collect and discharge the overflow water through a 1½-in. pipe at one side of the chamber. A sleeve within the overflow chamber holds the orifice plate down by means of pressure from the screw cap.

In operation the slurry of water and fine coal is pumped through the tangential feed nozzle and thereby caused to rotate or whirl. Under the influence of the centrifugal force developed by the rotary motion, the solid particles are thrown to the wall of the conical section and forced downward along the wall until they pass out of the cyclone through the underflow or bottom opening. The water, largely freed of solid particles, overflows through the central opening in the orifice plate at the top and leaves the cyclone by way of the overflow chamber.

In most of the preliminary work of determining the basic operating characteristics of the cyclone an artificial slurry was used. Coal from the Big bed in the Roslyn No. 3 mine, Ronald, Wash., was crushed to the desired top size and mixed with water to obtain a slurry having the pulp ratio required for a particular test. The top particle size employed in these tests ranged from 6- to 65-mesh, and the slurries varied from 0.3 to 39.0 pct solids.

Forms of Cyclone Underflow Product

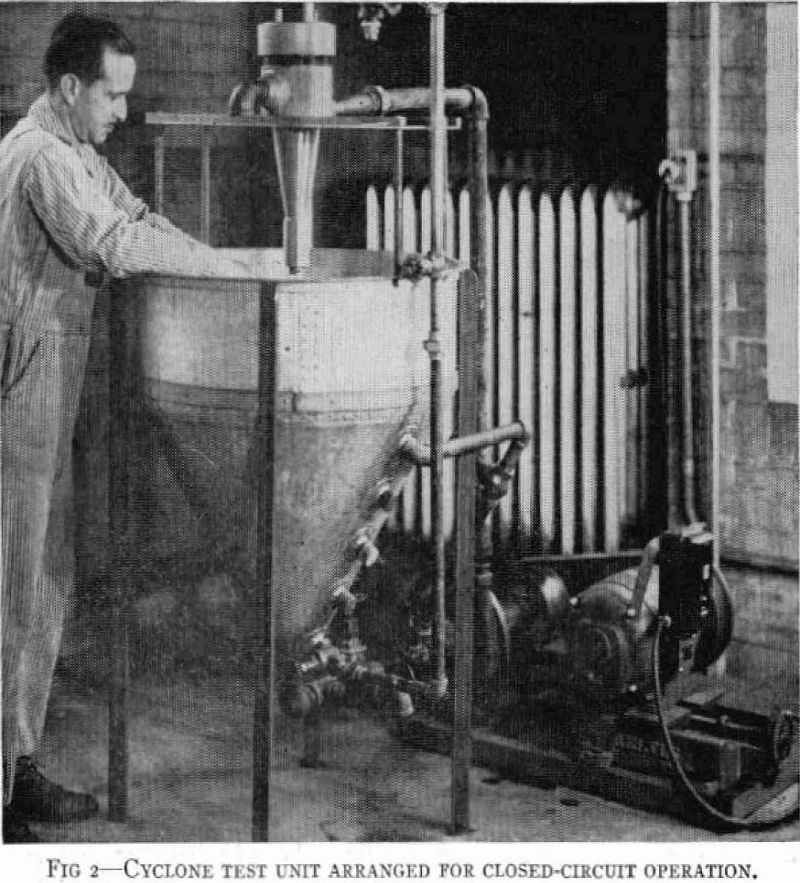

The form in which the underflow product emerges from the cyclone provides the best means of judging cyclone operation. On Parting the cyclone, if the sizes of the overflow and underflow openings are properly adjusted for the feed rate and the character of the slurry being treated, the underflow product will emerge from the bottom of the cyclone in the form of a strong spray or vortex of water and coal. If, however, the underflow opening is closed momentarily to permit a bed of coal to accumulate in the base of the cyclone, the vortex is replaced by a rotating or twisting solid rod of coal that resembles sausages coming from a mill. The “sausages” form, break off and drop, and then re-form. Fig 3 is a photograph of sausages that were produced from 35-mesh to o coal; they contained 65 pct solids as they came from the cyclone and retained their shape perfectly on drying.

In adjusting the cyclone, if the underflow opening is excessively large for the slurry being treated, too much water will reach the bottom and a sausage-type underflow cannot be obtained. If, on the other hand, the underflow opening is too small to provide egress for the solids as they are separated from the water, the cyclone will become overloaded. When overloaded with solids the speed of rotation within the cyclone is decreased, less centrifugal force is developed, and consequently the separation of solids from water becomes inefficient; under this condition an excessive amount of coarse solids will enter the overflow product. The overloaded condition is reflected in the form of the underflow product, which loses the twist that characterizes a good sausage-type underflow and emerges from the cyclone as a lazy, straight, solid stream containing more water than that in a sausage-type underflow.

Design Factors

At the outset of the investigation so little was known about the construction of the cyclone that much of the preliminary work involved investigation of elements of cyclone design. The relative size of the feed-nozzle, overflow, and underflow openings, the type of overflow opening, and a number of other design factors had to be investigated before the performance of the cyclone could be evaluated.

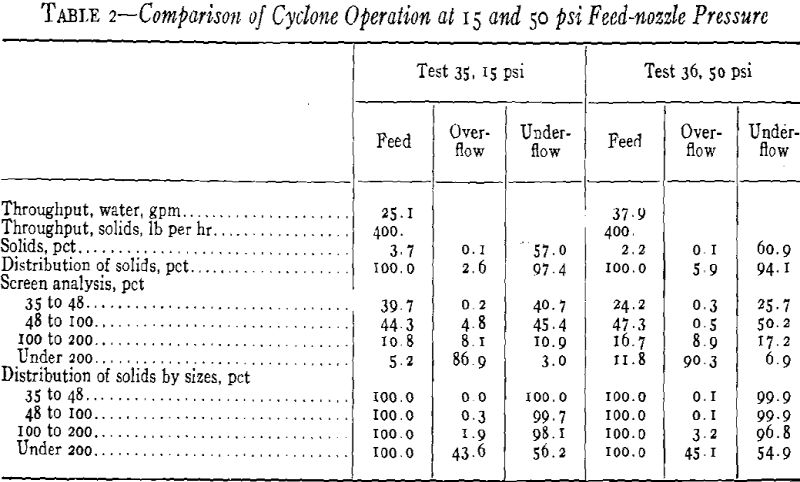

The feed-nozzle pressure employed in cyclone operation influences the capacity of the cyclone, and, since it determines the speed of rotation and thus the centrifugal force developed, influences the separation of solids from water. With the cyclones used in this investigation sausage-type underflows could not be obtained at feed-nozzle pressures of much less than 15 psi and consequently test work was confined to the range of 15 to 80 psi, the maximum pressure obtainable.

Operation or Cyclone on Centrifugal-Drier Effluent

The cyclone was installed temporarily in the central cleaning plant of the Northwestern Improvement Co., Roslyn, Wash., to permit observation of its operation under cleaning-plant conditions. The first slurry tried in the cyclone was the effluent of a centrifugal drier, which contains 30 to 35 pct solids as it leaves the drier but is diluted to 15 to 20 pct solids to facilitate pumping to the plant settling cone. The object of these tests was to see whether the cyclone could treat the drier effluent to produce an overflow water containing less solids than that present in the water currently wasted from the settling cone, and at the same time produce an underflow coal which, depending on its quality, could either be added directly to the washed coal or retreated on tables. A cyclone functioning in this manner would reduce the amount of solids in the water recirculating through the plant—an objective sought at most washeries.

Test 46 was made with a feed-nozzle opening of in. and a pressure of 50 psi, while tests 42 and 43 were made with a feed-nozzle opening of 17/32 in. and pressures of 15 and 50 psi, respectively. The greatest capacity was obtained with the larger feed-nozzle opening and the higher pressure of test 43, in which the cyclone handled 35 gpm of water and 3200 lb of solids per hr. The quality of the overflow and underflow products obtained in these tests was substantially the same; the overflow water contained from 5.4 to 6.0 pct solids and the underflow ranged from 61.8 to 65.4 pct solids. Virtually all of the solids coarser than 100-mesh were recovered in the underflow product, as was 92.6 to 98.7 pct of the material of 100- to 200-mesh size. About 70 pct of the material finer than 200-mesh was lost in the overflow water, however. Whether the solids contained in the overflow-water averaging 96 pct finer than 200-mesh could be recovered by retreatment in another cyclone is a problem that remains unexplored.

Operation of Cyclone on Springbook Slurry

The cylcone also was installed in the washery of the Springbrook Mining Co., Renton, Wash., to treat the overflow of a rectangular settling tank. This overflow product is a dilute slurry which currently is wasted to an outside settling pond. At many of the mines in this district the coal in such settling ponds is ultimately recovered by diverting the flow of slurry to a second or alternate pond while the coal in the first dries enough to permit loading it out, but the Springbrook slurry contains so much clay that it is an unsaleable, waste product.

The cyclone feed contained 4.0 pct of solid material, over half of which was finer than 200-mesh. From this slurry the cyclone yielded an underflow product containing 54.8 pct solids and an overflow water containing 1.8 pct solids. Solid material remaining in the overflow water was 99.8 pct finer than 200-mesh, which attests to the efficiency with which solids coarser than 200-mesh were recovered in the underflow product. No coal coarser than 150-mesh and only 0.6 pct of the 150- to 200-mesh solids present in the feed escaped with the overflow water. Material finer than 200-mesh was divided 76.1 pct to the overflow water and 23.9 pct to the underflow product.

Cyclone Elimination of Contaminating Solids from Process Water

Studies on the cyclone were initiated in July, 1947, at Northwestern University, as it appeared to offer a possible solution to the problem at a low capital and operating cost. If particles down to 10-15 microns can be eliminated, a large percentage of the original solids, including practically all the silt which causes a good share of the trouble encountered in the use of recycle water, will be removed. The cleaned water will be of a more consistent and optimum nature and together with its decreased effective viscosity may alleviate the problem of clay deposition on the washed coal. In performing the work, fundamental data were also taken in order that results could be used on any application of the cyclone. To simulate operating conditions, actual samples of wash water sediments from

different points in various coal-cleaning plants were employed in the experimental work. Washery waste sediments from the slurry pond of the Truax-Traer Coal Co. mine at Fiatt, Ill. were used in the majority of runs, but results were checked with other materials. While studies are still continuing, sufficient results have been obtained to justify the publishing of a preliminary report.

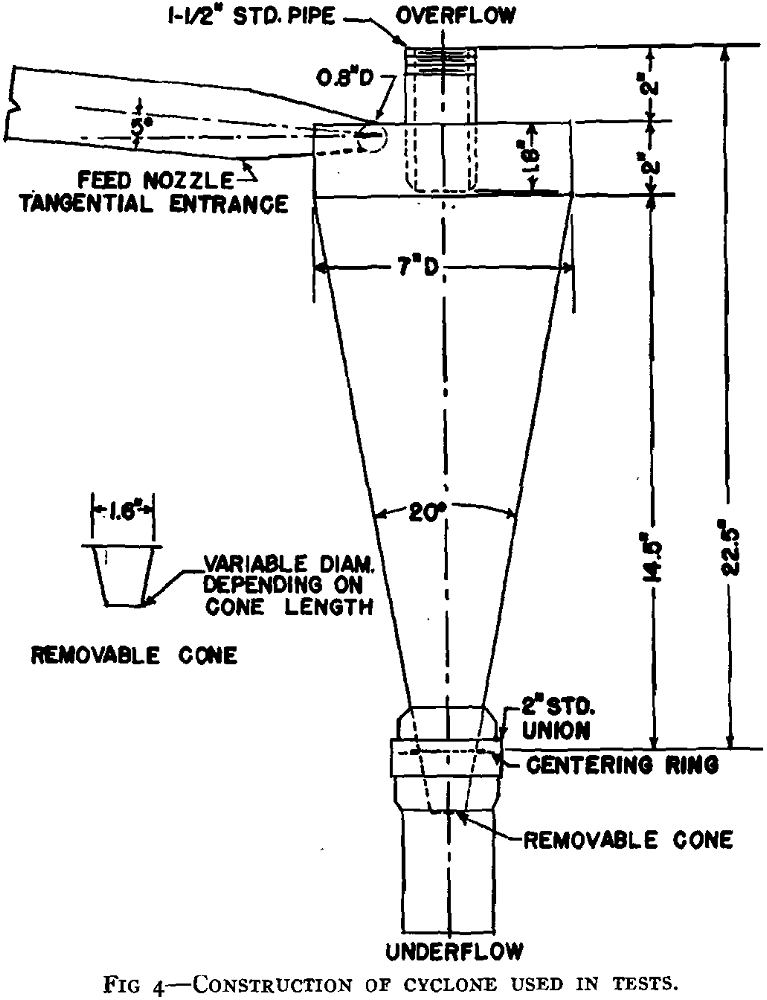

Description of Experimental Cyclone

The cylindrical ring is 2 in. high and 7 in. in diam, with a cover plate containing an overflow opening. The feed nozzle enters the cylindrical ring tangentially, as illustrated, and is a Venturi type nozzle with diam of 0.8 and 1.61 in. This nozzle is attached directly to the 1½-in. feed line. The entire conical section, cylindrical ring, cover and feed nozzle have been fabricated by rolling and brazing 0.04-in. sheet metal into the proper forms. The overflow dis-

charge line is a standard 1½-in. pipe tapered at the fluid entrance in the cyclone. Two inches above the cyclone cover, a standard 1½-in. union is placed in the line. This union has been faced off to facilitate the introduction of orifices in the line at this point. The underflow discharge has been completed by attaching a 2-in. union on the bottom of the cyclone. A centering ring is placed in this union and nozzles with the same slope as the conical section of the cyclone are placed in this ring to control the discharge. These nozzles have been cut off at various distances, creating different discharge areas for the underflow stream. A 2-in. pipe is connected to the union to prevent spraying of the underflow.

Operating Procedure

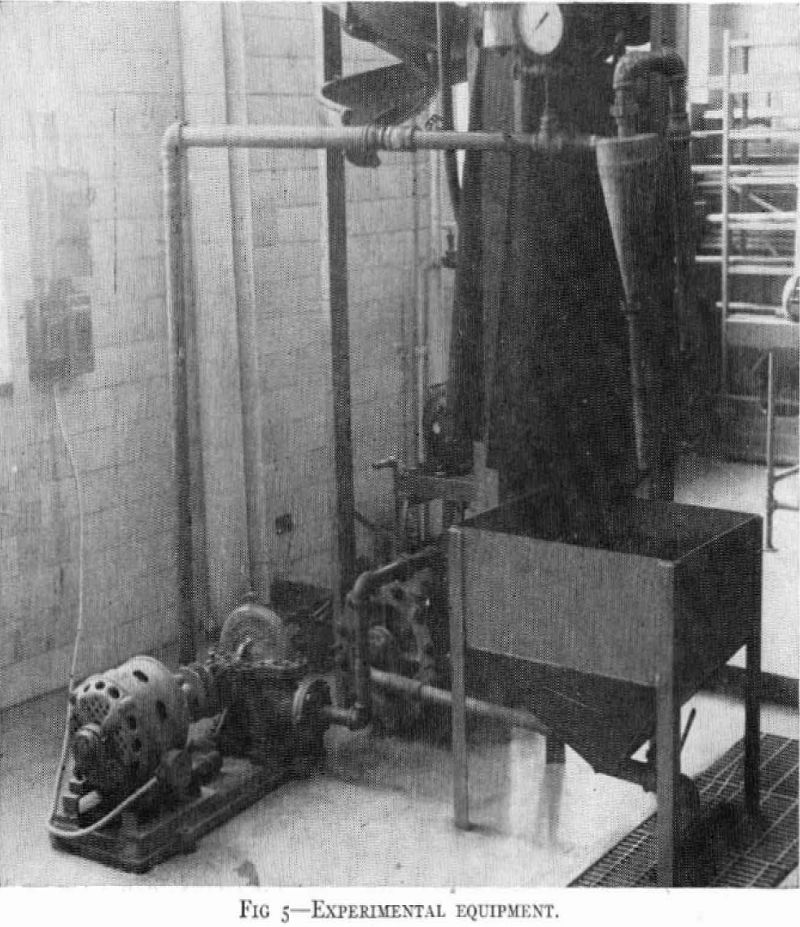

In performing the tests, the slurry is introduced into the collecting tank and circulated through the cyclone until equilibrium conditions are obtained. Time samples are collected simultaneously from both the overflow and underflow streams. Line pressure and character of the discharges are also noted. The samples are analyzed for solid concentration and particle size. The feed composition is calculated by combining the overflow and underflow streams.

Preliminary investigations were confined to determining the effect of operating variables on elimination efficiency. The factors examined were type and concentration of the underflow stream, slurry concentration, throughput or centrifugal force, volume distribution between overflow and underflow streams, types of sediment and pressure drop through the cyclone. With this work completed, conclusions could then be applied to the construction and operation of full size equipment.

Effect of Slurry Concentration—Theoretically, the solid concentration of the slurry should have no appreciable effect on the elimination obtained by centrifugal force. If sufficient force is present, a particle should be ejected to the underflow. However, as pointed out by Driessen, the particle must be eliminated from a suspension of higher gravity and viscosity than pure water and thus will act as though settling through a fluid of specific gravity of 1.0 to 1.3 depending on the nature of the feed slurry.

Effect of Variation in Sediments—As all previous runs had been made with silt bearing sediments, it was necessary to prove results on other materials. Accordingly, tests were performed on the overflow water from the fine coal settling cone of the Northern Illinois Coal Corporation at Wilmington, Ill. The minus 200-mesh fraction of these solids is largely clay and therefore, of a much finer nature. Results of two representative comparative tests are given in Table 14. It will be noted that equilibrium particle size for the two sediments is approximately the same. The poorer separation of the total minus 200-mesh fraction with the clay sediments can be attributed to the larger content in the feed of material finer than the equilibrium particle size.

All the minus 200-mesh fractions tested had approximately the same specific gravities of 2.3. Therefore no comment can be made on the effect of particle gravity other than that the equilibrium particle size will undoubtedly decrease as specific gravity increases. It is safe to conclude, however, that the nature of the particle other than gravity, unless it is unduly oily, will have no effect on the equivalent diameter of separation.

Pressure Drop in the Cyclone—Cyclone friction loss and not pressure drop is the measure of the static pressure and power a pump must develop in operating the cyclone. If the relatively small amount of slurry issuing from the underflow is neglected, Bernoulli’s equation may be applied between the inlet to the cyclone and the overflow discharge.

Due to the difficulty of formulating a theoretical friction loss equation for liquids until r values are determined, a direct empirical correlation similar to the above equation was attempted. Initially, water alone was used in order to reduce the number of variables.

Cyclone Application

From the preceding discussion, several proposals can be advanced concerning the design and operation of the cyclone.

Of prime importance is the practicability of using the cyclone for elimination of solid particles of sufficient size from water as well as for the preliminary dewatering of fine coal. It has been proven that a high elimination efficiency is maintained down to particles of about 12 microns equivalent diam for silt and clay sediments with the test cyclone. According to Stoke’s law, coal of 1.4 gravity compared with that of silt of 2.3 could be eliminated with the same efficiency down to approximately:

12 x (2.3 — 1.0)/(1.4 – 1.0) = 21.6 microns

Thus, if an industry, such as in coal beneficiation or mining, can tolerate particles of this size in the re-cycle water, the cyclone offers a very inexpensive solution to a troublesome problem. Capacity of the 7-in. cyclone used in these studies was about 40 gpm at 20 psi pressure.