Table of Contents

Hand mucking in shaft sinking operations is no longer necessary because several efficient methods and machines have been devised for this purpose for use in both vertical and inclined shafts. For years shaft sinking was considered the hardest and most dangerous job in mining and, consequently, the turnover in shaft crew was high. High turnover in personnel, particularly in shaft sinking, slows the operation because new men must be adjusted to the routine and peculiarities of the crew; accidents are more likely; and the cost of sinking increases. Mechanical shaft mucking has eliminated or alleviated the most disagreeable features of shaft sinking.

Scraper and Slide

In deepening its inclined Fisher Hill shaft in the Adirondacks, the Republic Steel Corp. mucked the broken rock by slushing with scraper and slide. Three tracks and a manway run the entire length of the shaft.

Riddell Mucker

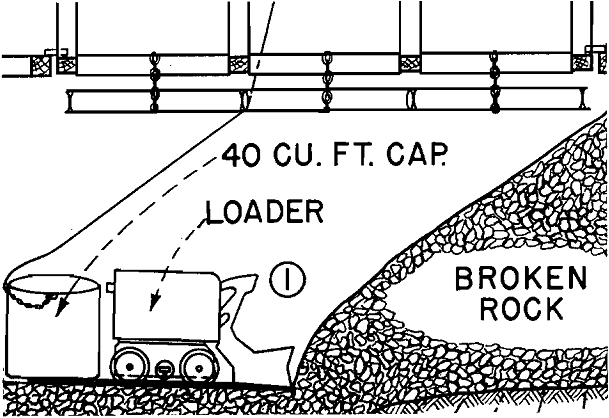

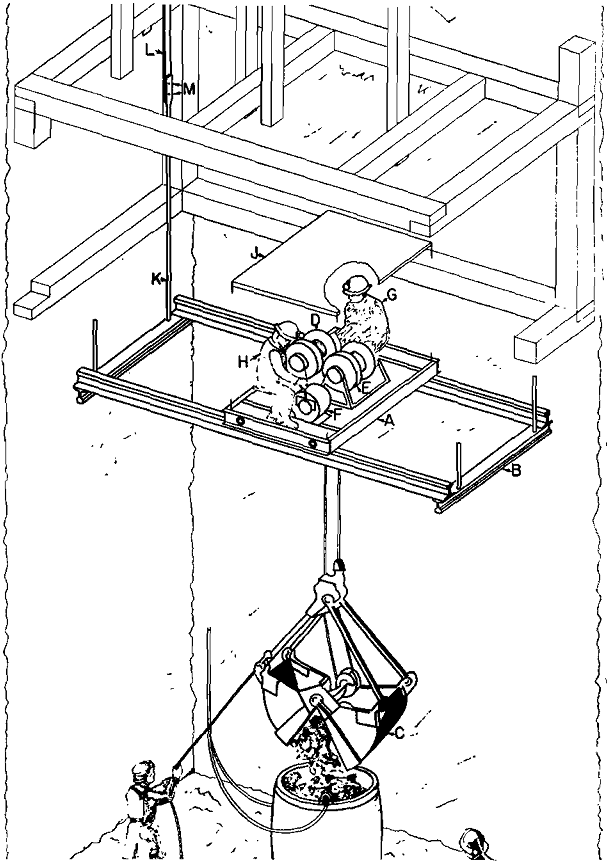

Conceived and developed in 1942, and designed to speed the expensive and onerous task of shaft mucking, the Riddell mucker is now in use in over twenty operations. In essence, it consists of a carriage, a frame, and a clamshell bucket. The steel carriage, on flanged wheels, moves horizontally along the long axis of the shaft, on a metal frame.

Hydro-mucker

Manufactured by the Hydrocrane Division of the Bucyrus-Erie Co., and used successfully at the Mather “B” shaft of the Cleveland-Cliffs Iron Co., the Hydro-mucker is a 3/8 yd clamshell-type bucket weighing 1400 lb. A vertically mounted hydraulic ram actuated by 5000 psi oil pressure opens and closes the bucket.

Boskovich Mucker

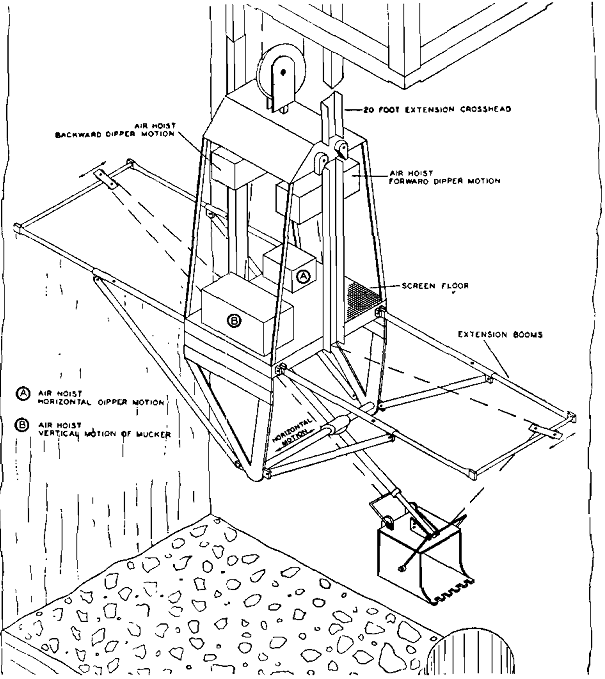

The Boskovich device, also constructed to operate inside timber, and easily placed in and removed from the shaft, was first developed and used at the New Park Mining Co’s. Mayflower shaft in Keetley, Utah. This device features a power shovel dipper suspended beneath a mine cage.