Table of Contents

A method is outlined for the analysis of large cores, developed primarily for the purpose of obtaining reliable data on fractured or vugular limestones.

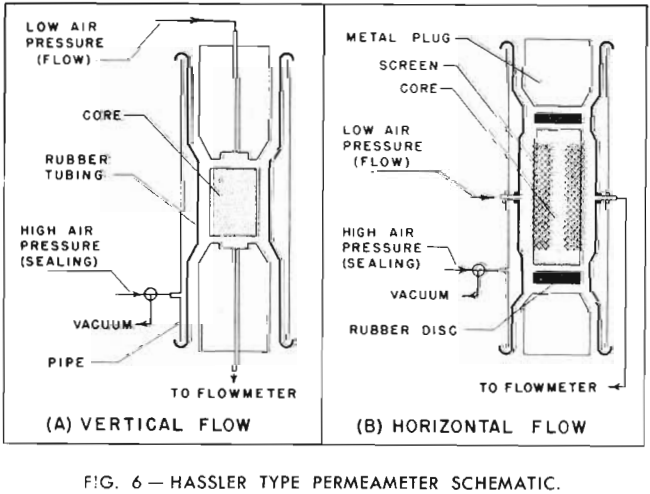

Porosity and fluid saturations are determined by a modified Dean-Stark extraction after initially bringing the samples to 100 per cent liquid saturation by a vacuum-pressure method. Horizontal permeabilities on the whole samples are determined in two directions, parallel and perpendicular to the direction of principal fracturing.

Core Analysis Procedure

Fluid Saturations and Porosity

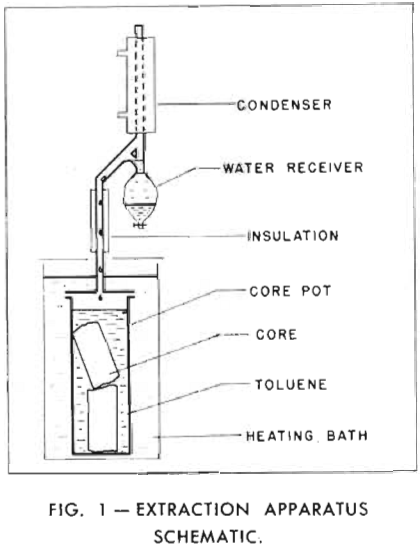

The core sample, in segments up to 15 in. in length, is marked, weighed and examined under ultra-violet light to determine the presence of oil saturation. If present, the approximate quantity of oil and its location on intercrystalline, fracture or vugular surfaces is noted. This information is carefully recorded. The degree of fracturing and/or vugular development is also noted. The sample is then placed in a pressure cell and the air evacuated with a high speed vacuum pump. This evacuation is continued only long enough to reduce the pressure to approximately the vapor pressure of water in order not to remove excessive amounts of water. Water is admitted to the cell and allowed to penetrate the sample under atmospheric pressure, filling the pore space initially occupied by air and replacing the small amount of water removed by evacuation. Pressure up to 200 psi is applied to force water into the smaller capillaries, and the sample is left submerged under pressure for an hour or longer. It is then removed from the cell, surface water wiped off, and re-weighed.

After extraction is complete the sample is placed in a constant temperature oven and dried for a period of one to two days. After cooling to room temperature it is re-weighed. The loss of weight, less the amount of water measured during the extraction, is the weight of the oil contained in the sample. This weight is corrected for an assumed density of oil to give the volume of oil in the sample. The summation of oil and total water gives the pore space of the sample, since the original gas content has previously been replaced by water.

Permeability

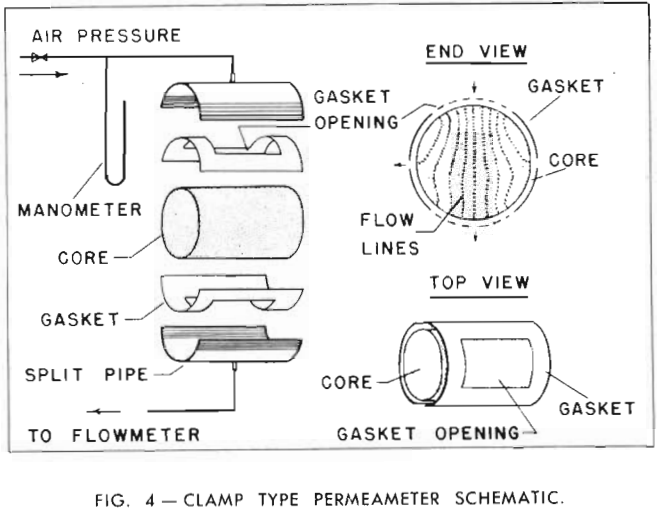

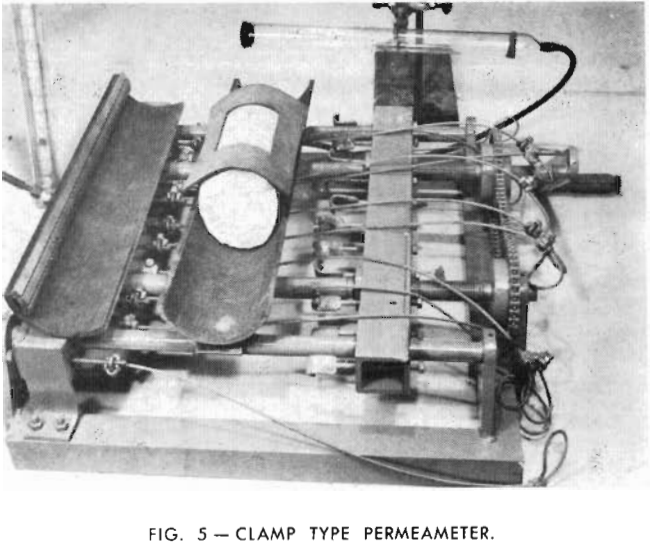

The extracted sample, or the largest segment if the sample consists of more than one piece, is placed in the cylindrical holder. The sides of the core are covered with two rectangular rubber gaskets, with openings whose length extends to within 1 to 1½ in. of the shortest length of the core and whose width extends over about one fourth the circumference. Two sections of split pipe of suitable diameter and with hinged pieces along their sides to provide a

good fit, are placed around the gaskets and a number of stranded wire cables are wrapped around the pipe. By means of a crank and worm gear these cables are tightened simultaneously so that considerable pressure is applied to all sides of the gaskets. This seals the core except for the two rectangular openings in the gaskets, a thin line

along the sides of the core between the gaskets, and the ends of the core.

Fluid Saturations and Porosity

It may be noted that two checks are available on the porosity as determined by the above outlined procedure. If the sample, after extraction, is allowed to cool under toluene and then weighed prior to drying, the weight of toluene divided by its specific gravity furnishes a check on the porosity. The agreement is generally found to be good. Another check is furnished, after extraction and drying, by resaturating the sample with water and determining the weight increase. The agreement here is also good. For example, a series of such measurements on seven samples of porous limestone gave a porosity value of 10.06 per cent by toluene and 10.13 per cent by resaturation. On eight low porosity samples of the same formation, the corresponding averages were 1.30 and 1.27 per cent respectively. On another formation, the corresponding values were 10.01 and 9.40 per cent; on still another, 4.94 and 5.16 per cent.

It may be mentioned that one example was encountered where the Dean-Stark extraction method failed to remove the water completely. If the procedure is applied blindly one would in this case come out with an incorrect high oil content and a low water content. In the example noted the apparent oil content was 0.6 per cent of bulk volume, the water content 0.8 per cent, the total porosity 1.5 per cent. The formation was a dense dolomitic shale, of permeability less than 0.001 md. It was evident, however, both from the appearance of the sample and the fact that the gas content was almost zero, that the formation was so tight that it would not give up all its water under the conditions of the extraction. This serves to emphasize that each analysis must be treated as an individual problem and solved accordingly.

Permeability

It has been suggested that the use of the above mentioned clamp type permeameter may give rise to considerable error due to the end effect when dealing with fractured core samples, i.e., there may be a channel connected to one end of the core which carries a disproportionately large amount of air. It is not denied that this may occur in some instances, but it is believed that the errors will be in both directions and will tend to balance out when a large number of samples are measured.

The accuracy of any one measurement is not high, but the approximate magnitude of the “equivalent” permeability is at least indicated and the measured value does take into account the flow capacity of both the matrix and the fracture or vugular system. Measurements so far made on samples of intergranular porosity have shown reasonable agreement with permeabilities of drilled plugs from the samples.

Analysis Results For Typical Formations

Matrix Measurements

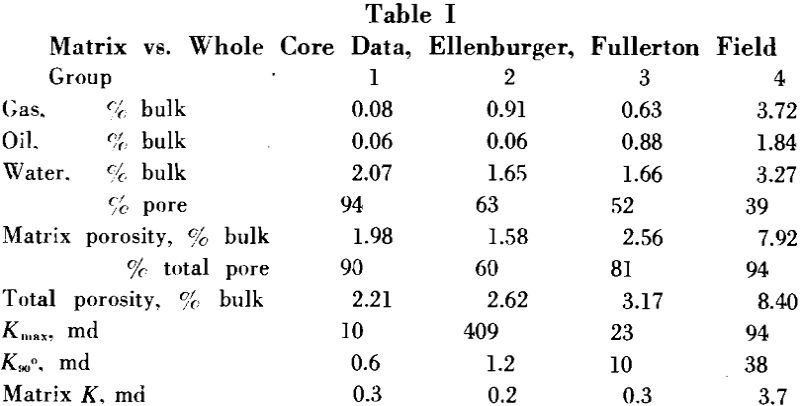

After obtaining analysis results on large cores from a section of Ellenburger formation from the Fullerton field, additional measurements of matrix porosity and permeability were proposed in order to obtain a clear understanding of the relationships involved. Fortunately the available samples showed a rather wide variety of characteristics ranging from dense and finely fractured to spongy, vuggy formation. Accordingly, on the basis of the special analysis results only, four groups of samples were selected. Group 1 consisted of 14 samples with very low gas bulk (from 0 to 0.29 per cent) and low oil bulk (0 to 0.40 per cent). Group 2 contained 13 samples of intermediate gas bulk (0.41 to 1.52 per cent) and low oil bulk (0 to 0.16 per cent). Group 3 contained 15 samples of intermediate gas bulk (0.06 to 0.89 per cent) and intermediate oil bulk (0.17 to 2.10 per cent). Group 4 contained 7 samples of high gas bulk (1.43 to 5.63 per cent) and high oil bulk (1.05 to 2.40). In general, group 1 consisted of dense samples with limited fracture development, group 2 had somewhat larger fractures and some open vugs, group 3 showed more development of intergranular porosity, and group 4 samples were intergranular and/or highly vugular.

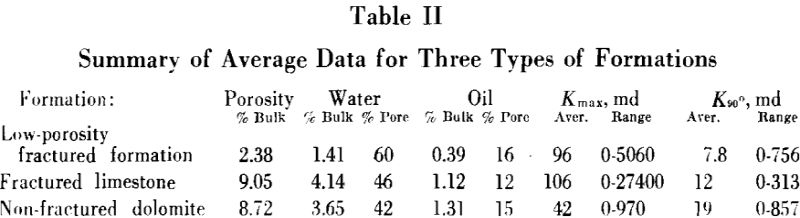

Average Data for Several Formations

The group of samples listed as “low porosity fractured formation” consisted primarily of Ellenburger and Devonian. The “fractured limestone” group included relatively high porosity samples with considerable fracture and vug development. The “non-fractured dolomite” group was comprised of samples from three crystalline dolomite formations possessing negligible fracture development. It is of interest to note the average water saturations, 60.0, 45.8 and 41.8 per cent of pore space respectively. These decrease in the same order that the K90° values increase. It should be pointed out, if the average measured total water saturations seem high compared to the values usually associated with such formations, that these averages include values for the lowest porosity samples as well as the high porosity samples, and that no attempt was made to differentiate between “barren” and “productive” pay.

Flushing of pore space with water from the drilling mud may have occurred and subsequent expulsion of water by liberated gas as the core was raised to the surface may have resulted in a final water saturation higher than the original connate water saturation. However, another possible cause is a statistical phenomenon which is often overlooked, but is known definitely to be of appreciable effect. The water saturations are averaged in groups with porosity as the controlling parameter.

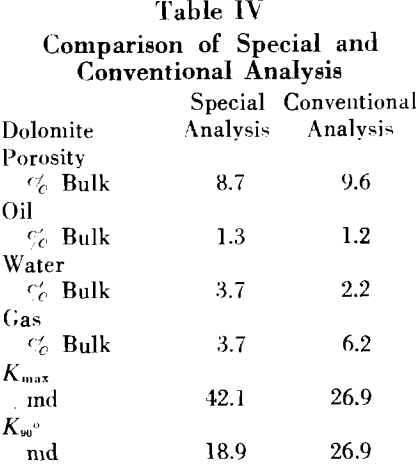

In summary, it is believed that the special analysis methods give somewhat more accurate fluid saturation and porosity values than conventional analysis, even on non-fractured formation. The special analysis may possibly tend to give slightly conservative values for reservoir oil in place. Conventional analysis on low-porosity formation which does not have fractures or large vugs has in the past probably given values for reservoir oil in place which are too high, but there is reason to believe that improvements in accuracy can be made here.