The problems encountered in efforts to explain the behavior of limestones, dolomites, and related rocks as concrete aggregate lie on the frontiers between the ignorance of the geologists and the ignorance of the engineers. The mineral composition and textures of the rocks have not been adequately explored and described, and the effects of mineral composition and texture on the performance of aggregates have been worked out in only a few cases. There are instances of unsatisfactory performance and some generalizations of those experiences. There are many more examples of satisfactory performance than of unsatisfactory, but there is practically no published information as to why a particular aggregate was satisfactory in a specific use.

The question of names to be applied to the carbonate rocks may appear academic, but it is of practical importance as long as there are specifications for aggregate that result in acceptance or rejection of rocks by name and as long as failure to make distinctions among the carbonate rocks leads to misunderstandings of their properties and of what may be expected of them in performance. Materials included in production statistics as limestone and tested for concrete aggregate as limestone range in fact from calcareous shale and calcareous or dolomitic sandstone and argillaceous limestone and dolomite to calcitic limestone and pure dolomite and to rocks close to calcitic and dolomitic marble. To take a simple example: consider two manufactured coarse aggregates, both dense and unweathered, one composed principally of crystalline calcite and the other of crystalline dolomite, but both known as limestone.

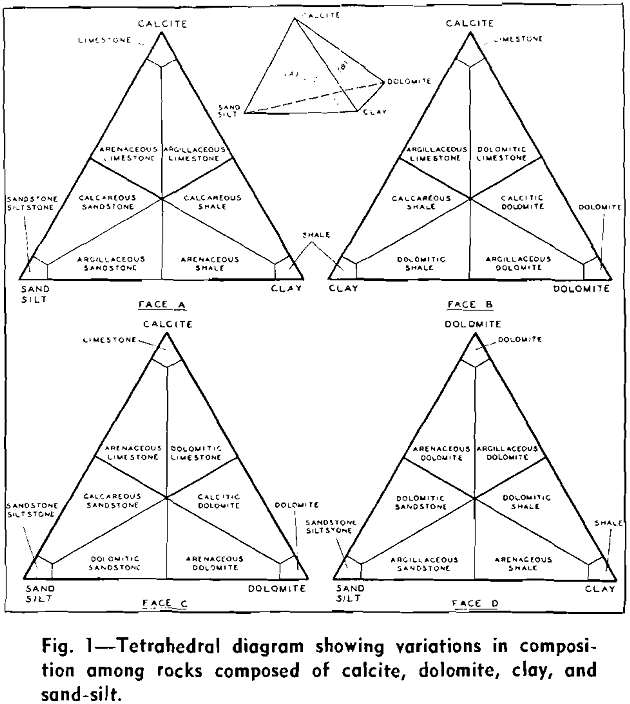

Classification of the carbonate rocks used as aggregate should be based on structure and on composition and texture. These last two are fundamental properties which can be related to aggregate performance. The relation of mineral composition to performance is quite often clear and easily recognizable. Less attention has been paid to texture, probably because it is hard to describe, almost infinitely varied in the carbonate rocks, and often difficult to explain.

The important groups of constituents to be taken into account are the carbonate minerals, the detrital constituents other than clay, the clay minerals, and the remaining, largely secondary constituents. Ordinarily either calcite or dolomite or both are the carbonates present, but others, for example siderite, are possible. It may be important to know the identity of the carbonate or to recognize the presence of both calcite and dolomite and the way they are distributed, since there are differences in thermal properties between them and differences in texture and interlock between calcitic limestones, dolomitic limestones, and dolomite.

It is convenient to discuss the effects of rock properties under two headings: those that influence production and those that influence use in concrete. The same properties are involved, but some of those influencing production act at that stage to eliminate potential sources, and some that make minor or negligible differences in production have marked effects in concrete.

Properties Influencing Production: To be produced as concrete aggregate, a carbonate rock must be available in adequate quantity for the intended use, must be present in beds thick enough to permit aggregate of the desired maximum size to be made, and must be strong and cohesive enough to be processed and emerge as a graded product in the size-ranges desired. The second requirement eliminates some thin-bedded deposits as sources of aggregate for mass concrete, although they are suitable for pavements or buildings. The third eliminates many of the consolidated but soft Cretaceous and Tertiary limestones of the Gulf Coast that crumble when they are crushed.

Properties Influencing Use: Performance of any concrete aggregate depends on its physical condition, its physical and chemical properties compared to those of the matrix in which it is placed, and the circumstances under which the concrete is exposed. Great variations may therefore be expected in performance of any one coarse aggregate if it is used in combination with several fine aggregates, in different structures, different concrete mixtures, and different exposures.

Another investigation made at the Waterways Experiment Station provides some information on the relation of type of clay in limestone to the durability of concrete as measured by accelerated freezing and thawing tests. This series of tests included nine carbonate coarse aggregates, seven of them calcitic limestones, one dolomite, and one dolomitic limestone that contained considerable sandy limestone and calcareous sandstone. Standard physical tests and thorough petrographic examinations were made of these aggregates.

The relation between durability factor and difference in thermal coefficient between coarse aggregate and mortar that had been found in the investigation reported by Callan was also apparent here, but other relations became clear when freezing and thawing results, thermal coefficients, petrographic data, and absorption were all considered. The clay minerals found in five of the nine aggregates belonged to the kaolin group and amounted to 1 to 5 pct of the total.

While there were not enough aggregate combinations tested to make correlation analysis useful, the degree of association between type of clay mineral and durability factors above and below 80 could be computed by use of the chi-square test. This calculation indicated that the probability of chance occurrence of the association between swelling clay and durability factor below 80 was less than 2 in 100.

The data so far available indicate that 5 pct or less of kaolin clay in dense limestone may not injure the performance of the limestone as aggregate, but that similar percentages of montmorillonoid clays in limestone with 1.5 to 2 pct absorption may produce a noticeable effect on durability as determined by accelerated freezing-and-thawing of concrete, and 10 to 20 pct of montmorillonoid clay in limestones which have 2 pct or more absorption, used in pavement laid on poorly drained foundations, may cause the pavement to fail.

Dolomitic limestones and dolomites have not been as well represented as limestones among the carbonate aggregates tested at the Waterways Experiment Station. One group of six dense calcitic dolomites was examined and tested during an aggregate survey made for a dam in Virginia. Four of the six were quite pure calcitic dolomites. One contained some cherty and some sandy dolomite as well. One was argillaceous dolomite, but the clay was not identified. All had less than 1 pct absorption. When each was tested in freezing-and-thawing of concrete in a mixture containing manufactured sand from the same source, all had durability factors of 85 or more, except one pure sugary-textured highly fractured dolomite.

Four additional examples of alkali-aggregate reaction in field concrete containing limestone or dolomite as coarse aggregate have been discovered or confirmed as the result of the examination of samples by the writer. They have common factors suggesting that the alkali-aggregate reaction in these cases may be a secondary consequence of other deterioration in the concrete, rather than a major or a primary cause of deterioration. In three cases chalcedonic chert and glassy volcanic rock fragments, constituents of the fine aggregates, were the reactive ingredients, and there were no signs of reaction by the coarse aggregate.

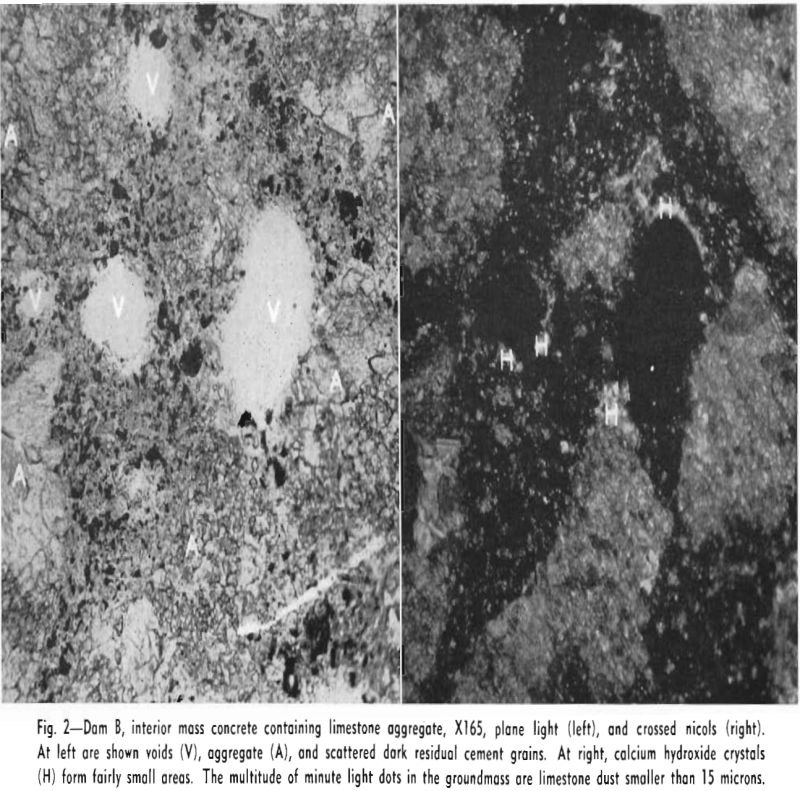

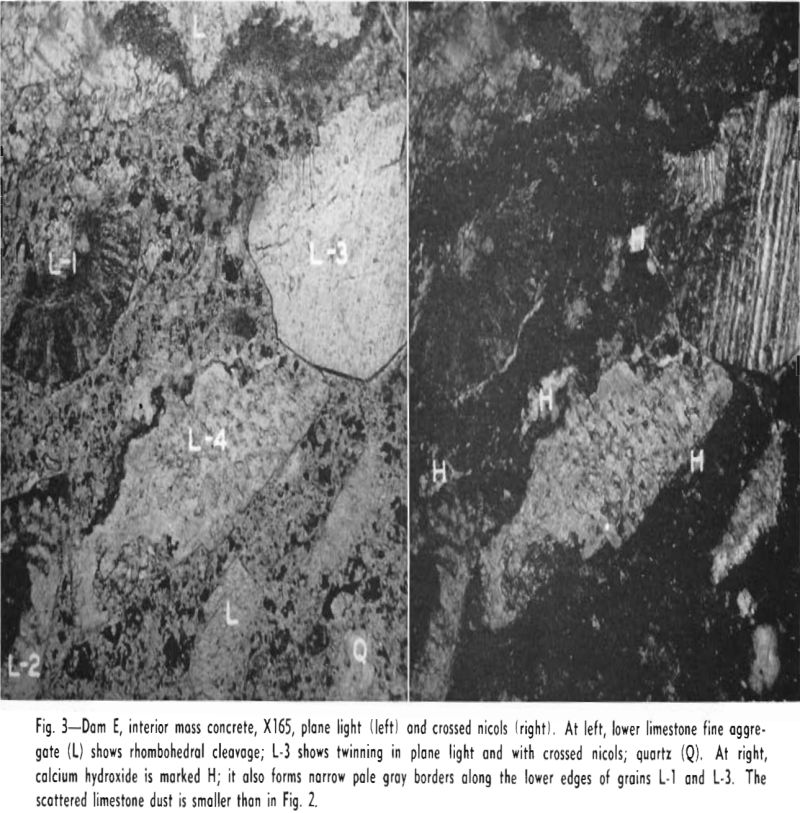

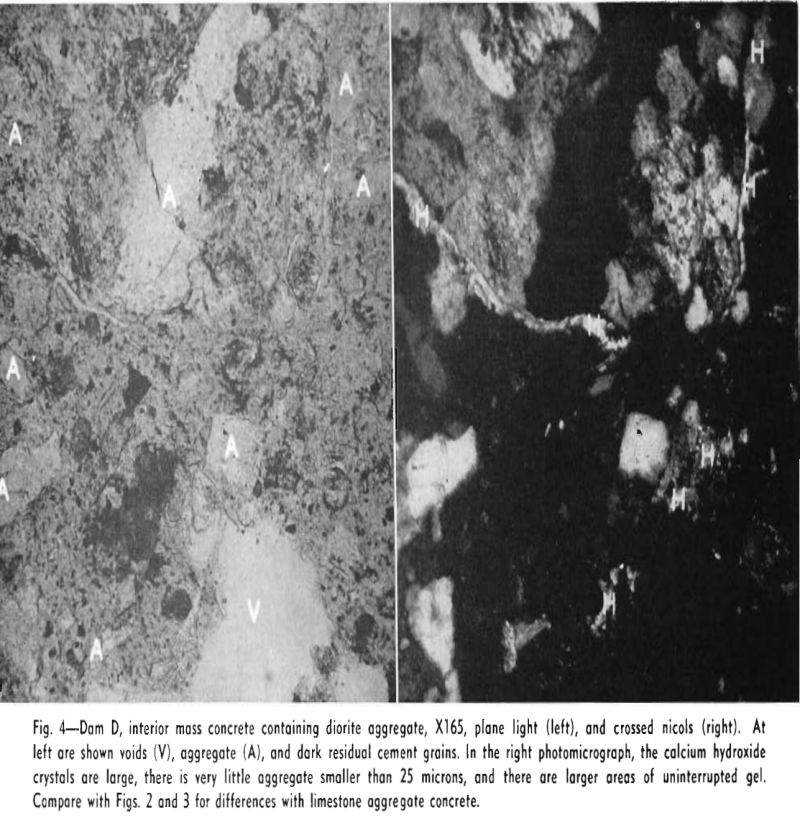

The examples so far discussed to illustrate effects of variations in properties of carbonate aggregates with changes in composition have been concerned with variations among several groups of carbonate aggregates: limestones and dolomites, argillaceous limestones and dolomites, and cherty limestones. The last group of examples will illustrate variations in the properties of concrete resulting from differences between some carbonate aggregates and some non-carbonate aggregates.