Table of Contents

This paper summarizes the results of an investigation sponsored by The Coates Steel Products Company. The objective was to determine the relative effects of certain chemical and physical properties on the wear resistance of grinding balls when grinding cement. In making this study, a number of types of balls were used in both dry and wet grinding in commercial ball mills.

Processing of Grinding Balls

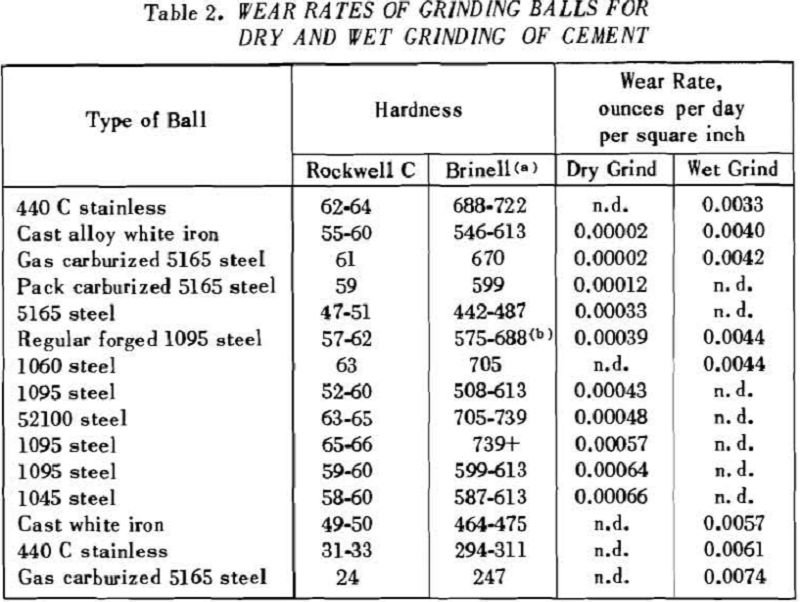

In order to determine whether the properties of grinding balls, namely, composition, microstructure and hardness, can be related to the rate of wear, the balls used in this study were selected to represent various combinations of these properties. It was recognized that the mechanism of wear was not the same in the wet mill as in the dry mill. Therefore, the types of balls tested in each of the two environments were not necessarily the same. However, all of the types of balls evaluated in the dry mill were tested simultaneously for one time period, while those evaluated in the wet mill were tested simultaneously for three different time periods.

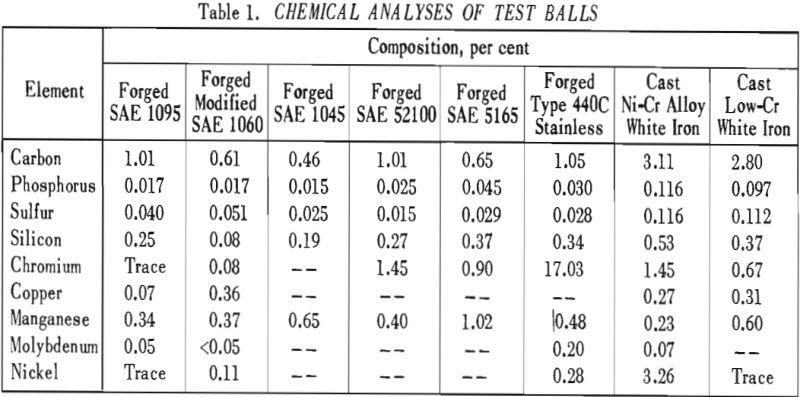

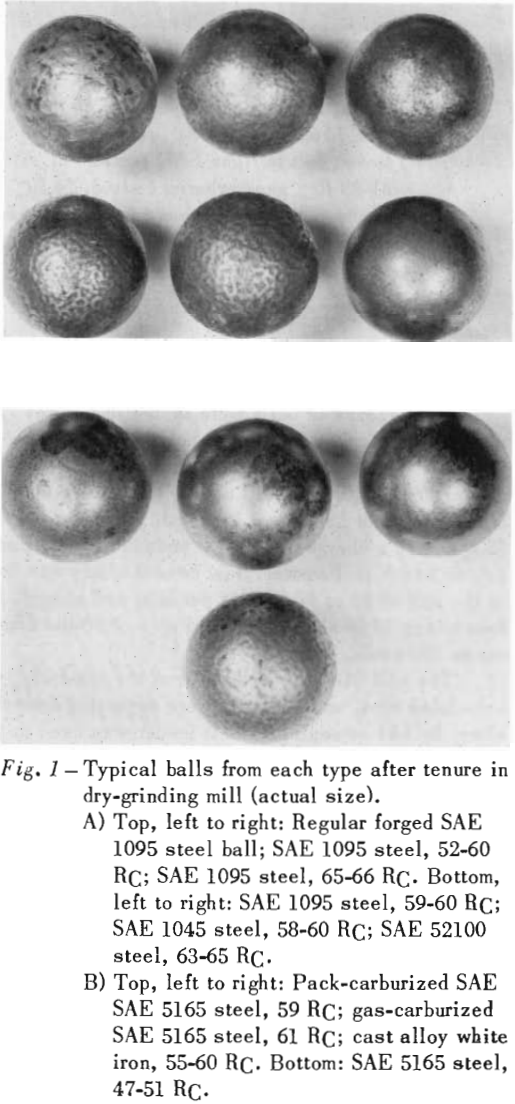

Regular production forged SAE 1095 steel balls were used in both the wet and dry mills. They were forged to a nominal diameter of 0.940 inch and quenched in oil from the forging temperature. Each retained a partially decarburized surface layer from the forging bar stock; the maximum depth of this layer was about 0.030 inch and the decarburization was negligible where the ball was sheared from the bar. The hardness at the surface was 40 to 46 Rockwell C in the partially decarburized area and 57 to 62 Rockwell C in the areas not decarburized. The hardened zone extended to a depth of about one-third of the radius.

In order to eliminate the effect of the decarburized layer, a set of production balls of SAE 1095 steel was forged to about a 1-inch diameter, quenched in oil from the forging temperature, and ground on ball-bearing grinding equipment to a 0.940-inch diameter to remove the decarburized layer. The balls hardened zones were similar to those in the previous set. The hardness of the finished surfaces was 52 to 60 Rockwell C. A slight amount of decarburization apparently remained after the removal of about 0.030 inch from the surface. Balls of this type were tested in the dry mill only.

Two types of heat-treated alloy steel balls were used in the dry-grinding tests. One set was forged SAE 52100 steel hardened by oil quenching to 63 to 65 Rockwell C hardness. The microstructure consisted of martensite and fine carbides that had not been dissolved during the austenitizing treatment. The other set was forged from SAE 5165 steel, and heat treated to a Rockwell C hardness of 47 to 51. The structure was tempered martensite.

Irradiation of Grinding Balls

The specimen balls were weighed, irradiated to different levels for each group, and the specific radioactivity of each ball was determined. This technique has been described by Pobereskin, et al. One irradiated ball from each group was reserved as a control. For the balls used in the dry-grinding test, one group was given the minimum irradiation time and the remaining nine groups were irradiated for times that were increased by 33 per cent from that of each preceding group.

Irradiation time for each succeeding group was increased by 50 per cent. These changes in the irradiation procedure were made to compensate for the expected increased rate of ball wear and to allow for greater decay in radioactivity resulting from the longer tenure in the mill.

Dry and Wet Cement Grinding Procedures

Ten groups of balls with thirteen to eighteen balls per group were charged into a “finish grinding” (dry) cement mill operating with 90,000 pounds of balls. Balls normally charged in this mill were 1 inch in diameter. This mill was 7 feet in diameter by 26 feet long, and operated in closed circuit with air separators to produce a 95 per cent minus 325-mesh product.

In evaluating the balls on the basis of weight loss or wear, the wear rate in ounces per day per square inch of surface area was determined for each group tested in the dry mill and for the three periods for each group run in the wet mill. These data are based on the average surface area of the ball during the testing period. The wear rate for these balls was 0.0048 ounce/day/square inch for the 260-hour period, 0.0041 ounce/day/square inch for the 1510¬hour period, and 0.0042 ounce/day/square inch for the 3410-hour period.