Wet scrubbing of fine coal from Thermal dryers poses a number of problems in adapting the gas cleaning equipment for required clean-up of the fine particulate matter.

A wet cleaning apparatus traps the matter suspended in the gas stream in a scrubbing liquid, generally water and a great variety of equipment is used. They include wet spray towers, packed tower centrifugal devices, Venturi scrubbers and various types of sieve trays.

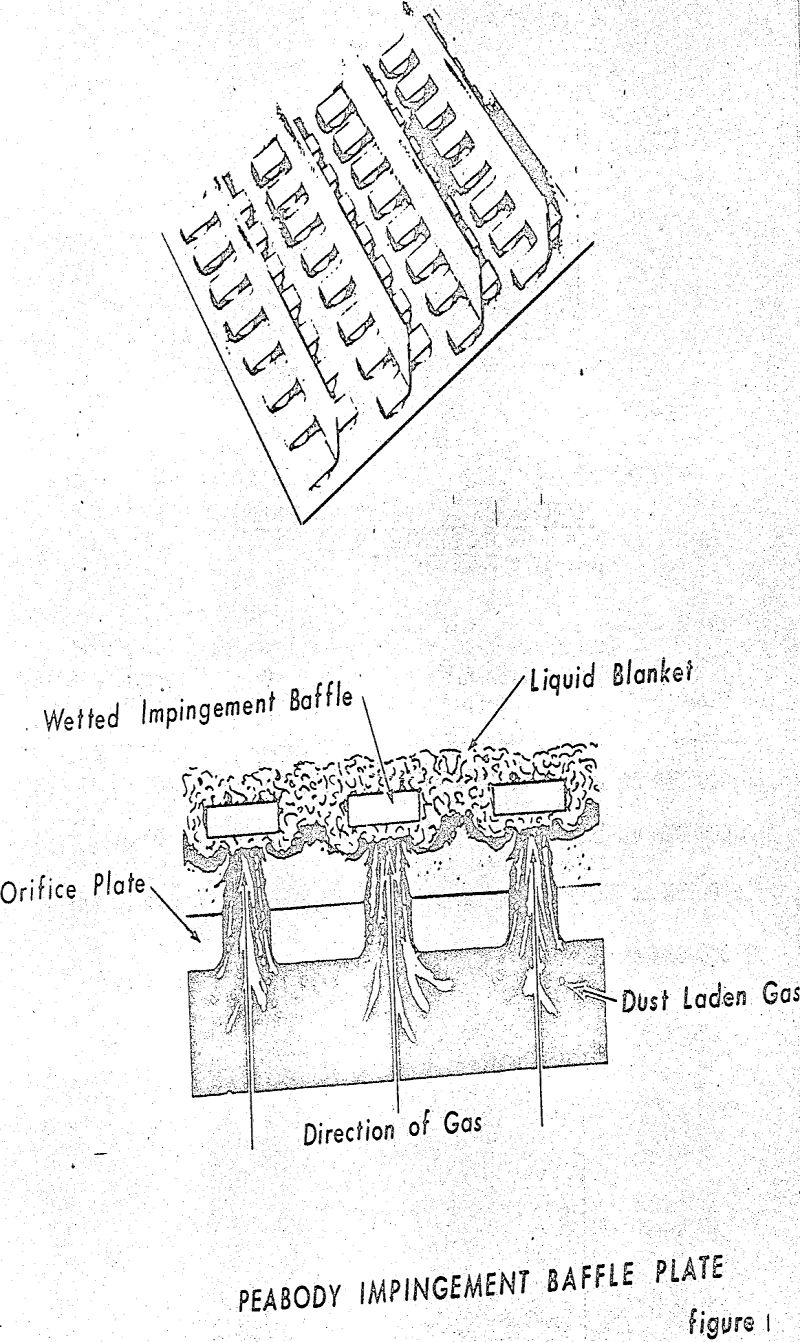

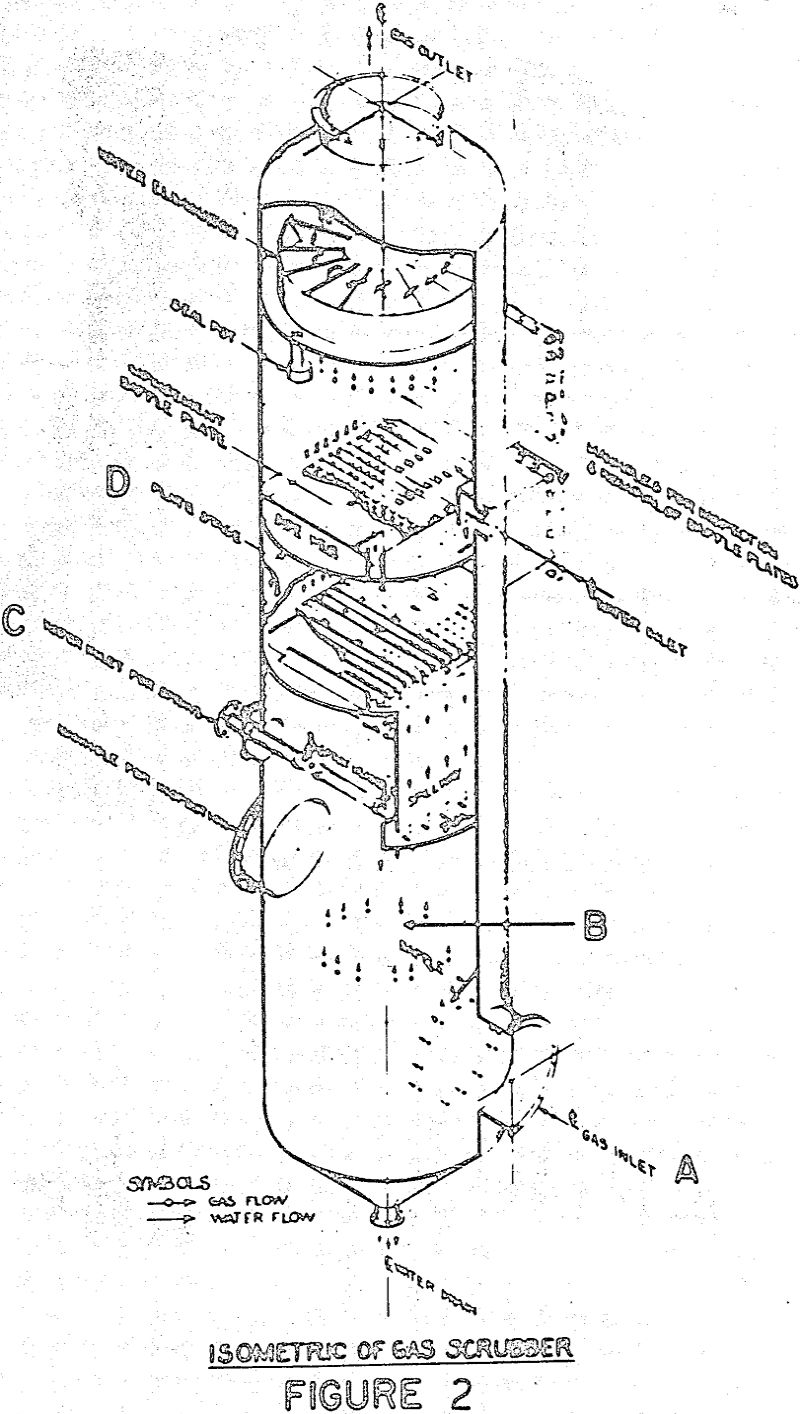

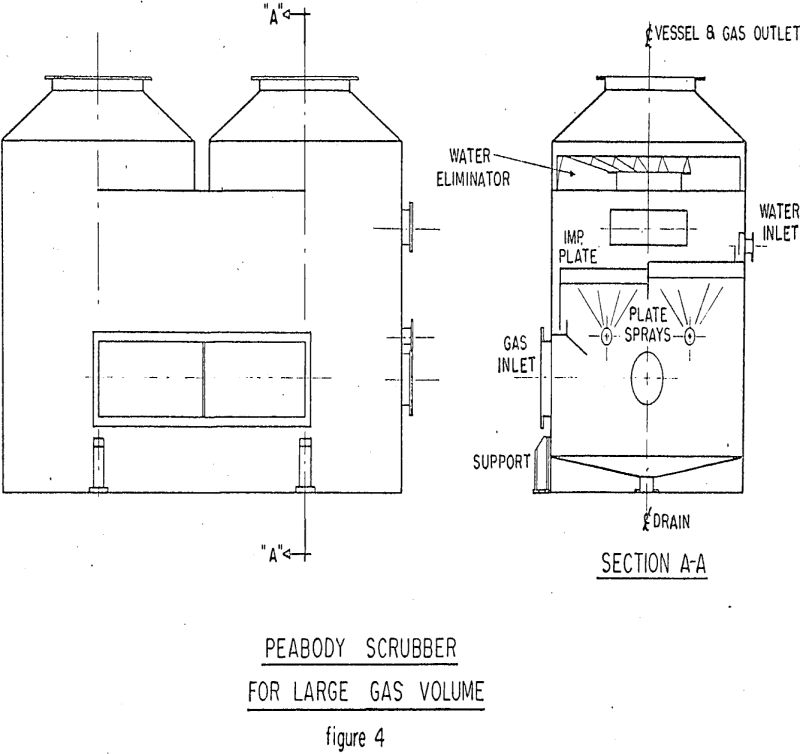

The Peabody gas scrubber uses basic principles to effect gas cleaning; sub-division of the gas into small streams, impingement of the small gas streams against wetted targets at comparatively high speeds and centrifugal action to separate the particle from the gas stream. Figure shows a typical Peabody impingement baffle plate cleaning stage. This type of contact is used either singly or in combination with additional gas cleaning stages depending on the degree of difficulty of gas cleaning.

A typical performance curve showing cleaning efficiency of a single Peabcdy type tray is shown in Figure 3. A curve of this type is characteristic of all wet scrubbers. There is considerable variation in the performance of various types of wet collectors particularly in the range of 0 to 5 microns in size. It should be noted that a single tray Peabody shows very high efficiencies in removing particulate matter down to one (1) micron in size and below this one (1) micron size range a fairly steep drop in the 0 to 1 micron size takes place.

It is in the size range where the specification presents an obscure picture. Particle size information in the 0 to 1 size range is difficult to obtain and the reliability of this information when it is available is subject to question such that for all practical purposes it cannot be used for predicting design performance.

It can serve however as a guide to applying gas scrubbing equipment and particularly constitutes a danger sign as to the presence of a high percentage of sub-micron particles which contribute directly to very low performance of wet scrubbers operating in the pressure drop range of 2 to 10″ W. C.