Modern high capacity underground mining machinery is a complex of mechanical, electrical and hydraulic components which have greatly increased capability over similar components of mining machinery of ten and even five years ago. Looking into the future I feel certain in stating that there will be changes equally great in the coming five and ten year periods. With this premise in mind, i should like to bring to your attention some of the things that do and will have a continued major impact on the industry, particularly as they relate to the maintenance and operation of these machines of increasing capability.

I am sure that the subject “Power Supply” for mining machinery is one which is not only an everyday subject of discussion among you, but that so much has been said and written that it will be difficult for me to present anything new and constructive. However, the subject is of such vital importance to good performance that I would like to discuss some of the often overlooked fundamental factors involved.

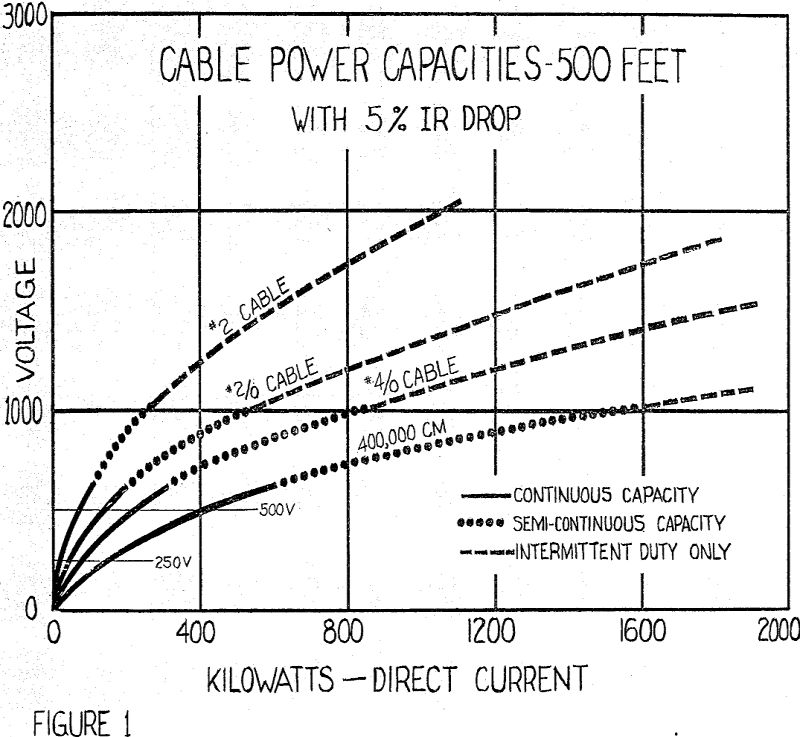

For any size of conductor, the same transmission distance and the same voltage drop, expressed as a percentage of line voltage, the power transmittable varies as the square of the voltage. For example, if the supply voltage is 100 the kilowatt transmittable with a 5% voltage drop for a distance of 1000 ft. may be 1 kilowatt, but with this same transmission cable and 1000 volts the power transmittable will be 100 kilowatts.

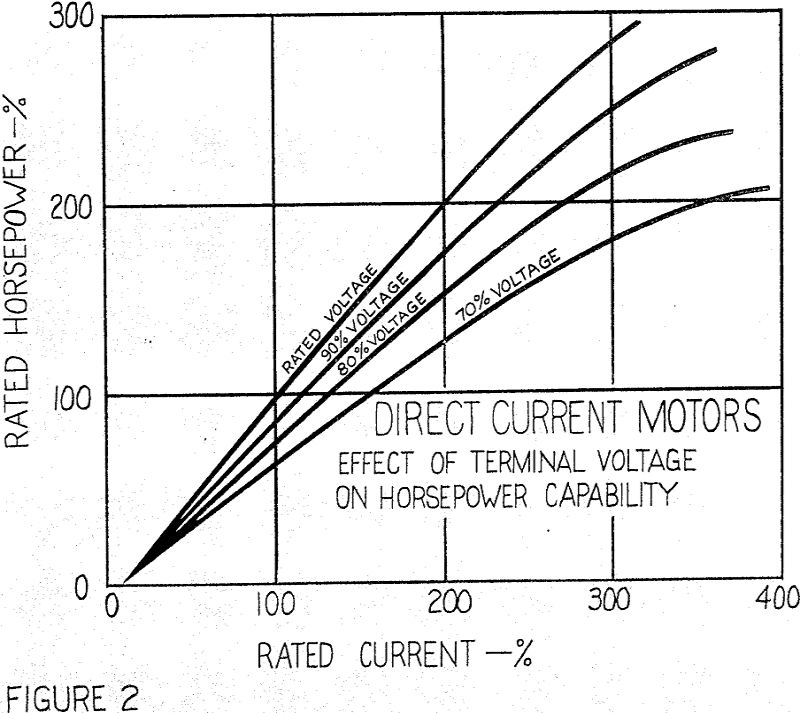

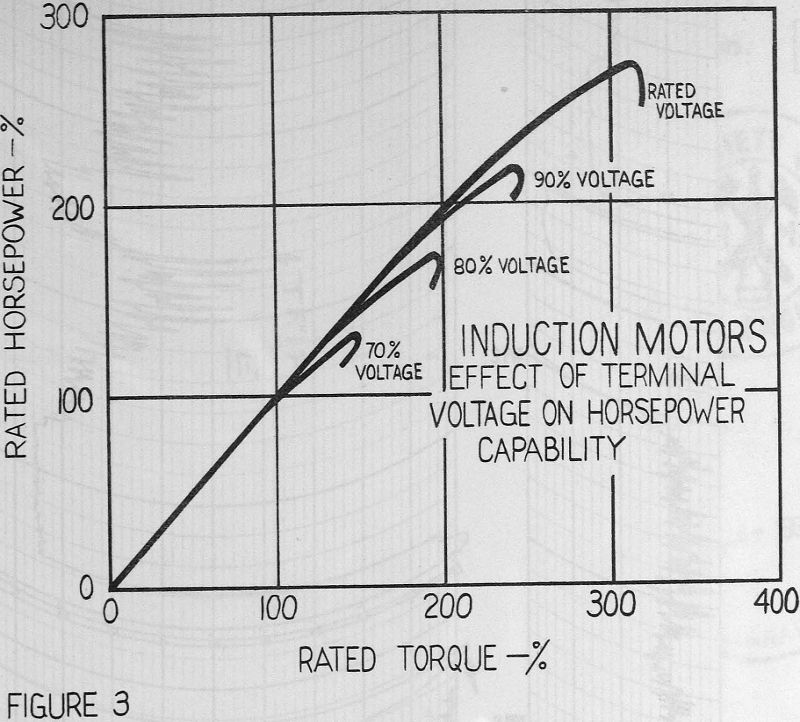

Because of rapidly changing load conditions it is, of course, impractical to maintain constant voltage at the motor for all loads. The important consideration is that motors be supplied power at their terminals at substantially constant voltage for all operating conditions, and this is generally defined as ± 10% of nameplate voltage.

The significance of these few remarks is that the power supply to underground mining machinery should be “stiff” to obtain the capacity of which the machine is capable. The 30% voltage drop values, which have such an adverse effect on machine performance, are not at all uncommon in underground mining operations. Proper selection of voltage, primary and secondary power cables, low voltage lines as short as possible and higher capacity transformation equipment are a necessity to realize the capability of modern high capacity mining machinery.

Temperature sensitive protective devices are now available for motors. Usually these devices, which operate on the principle that there is a rapid change in resistance at a specified temperature, are used as indicators rather than “shut down” controls. This is proper and practical as long as the operator is trained to use the temperature indicator, which may be an amber light for caution and a red light or some other form of warning for dangerous temperatures, to cause him to reduce the horsepower being applied or find the cause. In other industries, railroads for example, it has been found necessary to de-energize the equipment automatically when the caution (amber) signal is disregarded and the danger (red) signal appears.

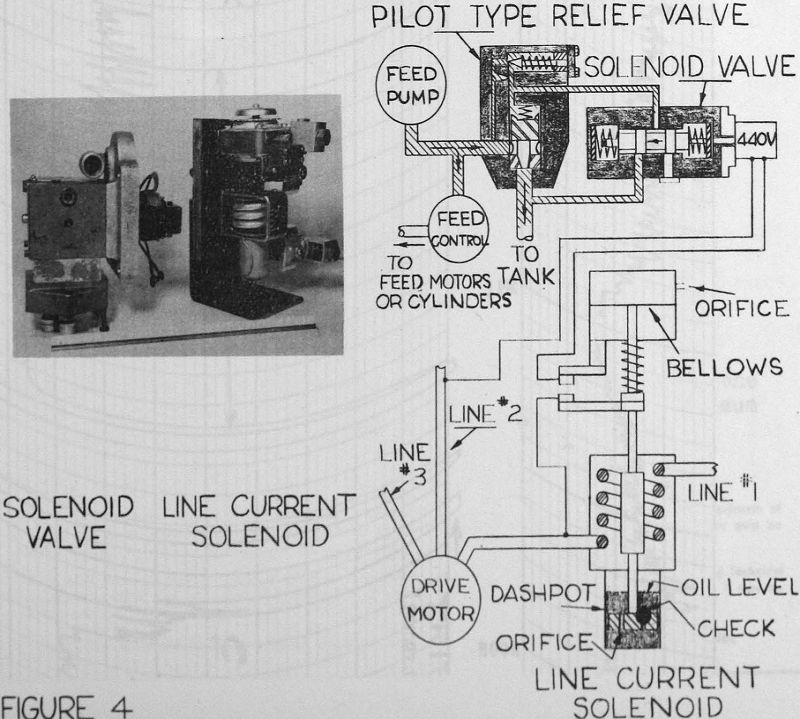

Many underground mining machines are equipped with hydraulic feed controls. These permit an infinitely variable rate of advance of such machines as continuous mining machines, cutting machines, etc. Usually the feed control is manual with the machine operator adjusting the control to suit conditions or to fit his experience. Here again, an inverse time element device is a proper type of control, as the device can be set to regulate the rate of power flow to the capability of the machine. T

Machines of high mining capacity require hydraulic components with capabilities of 100 Hp. and more. At 2000 PSI approximately one gallon of fluid per minute per horsepower is required. (100 Hp. 100 GPM). A one-half inch I.D. pressure hose (one inch O.D.) is suitable for no more and preferably less than 10 gallons of fluid per minute. These few figures along with space for servicing serve to illustrate the need for the highest pressure equipment available, wherever high horsepowers are necessary to provide the fast and positive motions which permit the design and manufacture of high capability machines.

From a mechanical design standpoint modern high capacity mining machines are not different from such machinery as off-highway equipment, tractors, main-line locomotives, aircraft components and a good many other types of variable speed and variable duty equipment. A characteristic of this type of machinery is that the best possible use must be made of the available space.

Related:best ear protection for loud machinery