Table of Contents

One of the major problems in the purchase and sale of coal shipped in lake or ocean going vessels has always been, the difficulty in obtaining a true analysis of the shipped coal’s quality because of faulty sampling by manual methods. As long as coal was sampled according to standards set up by ASTM methods designated D 492-48 there generally were no quarrels with the results obtained. However, due to varied weather conditions and because of the large number of cars sampled, there is no assurance that prescribed manual methods of sampling will always be followed.

Test Procedure

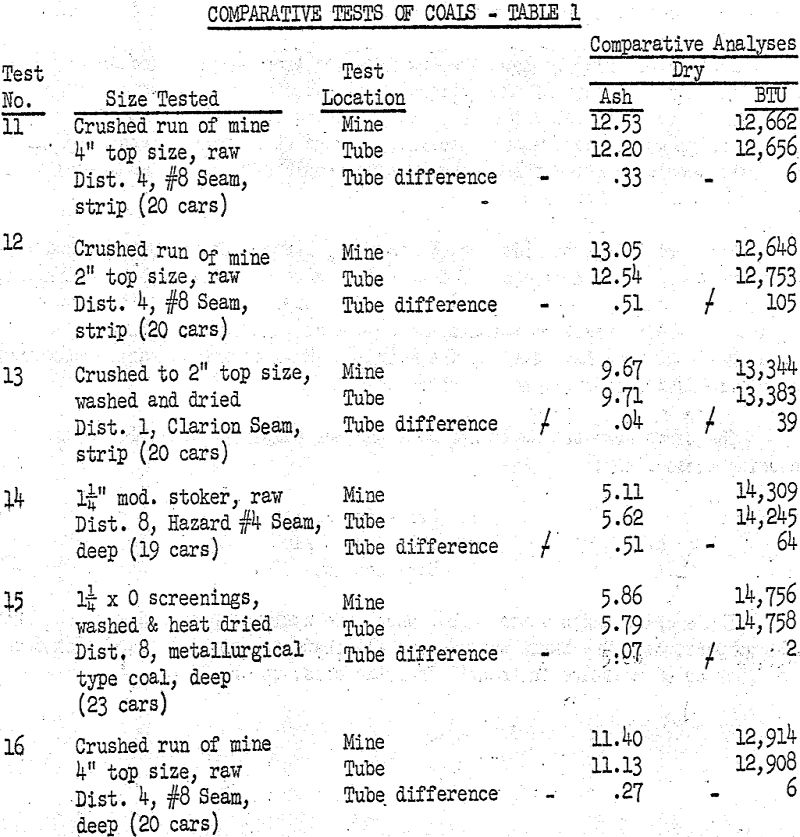

In preliminary tests made prior to those reported in this paper, most of the coal used was 4″ crushed run of mine raw coal from a strip operation in the Ohio 8 Seam. This coal was considered difficult to sample because of its variation in size consist as well as different size fractions of the coal that vary in ash content and BTU value. Also, the 4″ dimension would represent about the largest top size coal shipped to consumers of sizeable tonnages in the Great Lakes area.

Burlap bags with plastic liners were used for all sampling work. The plastic liners retained the moisture and prevented loss of fines.

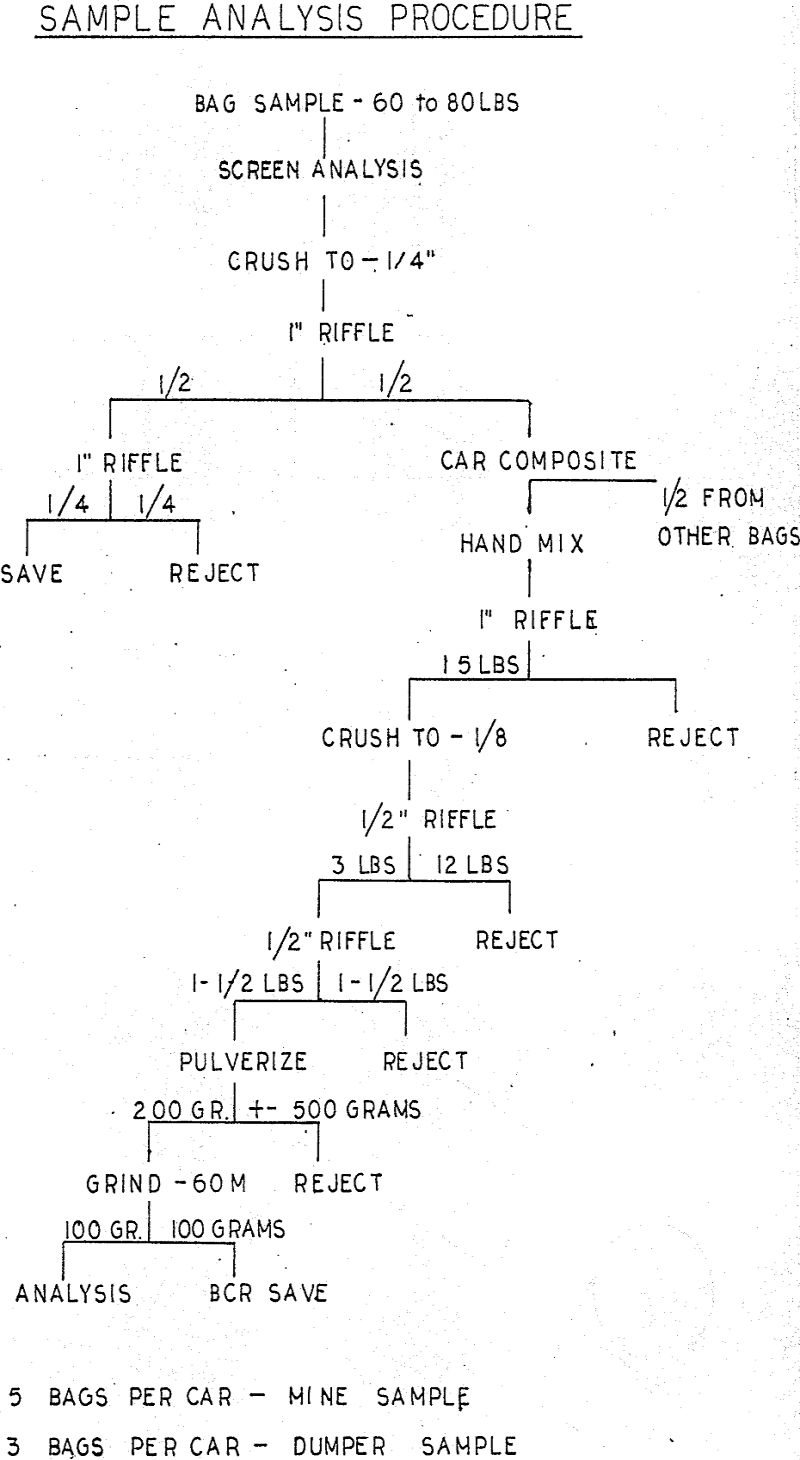

In the first five tests reported, Numbers 11 through 15, all of the cars were sampled at the mine by hand methods. This was done by cutting the stream of coal with a container that was large enough to pass across the stream without any spillage. Usually five to seven cuts of the stream of coal were necessary to get enough coal to fill a sample bag.

No attempt was made to be sure that a certain percentage of 50 or 70 ton cars would be sampled for any given test. Cars were loaded in the sizes as delivered by the railroads. Records were kept of the size care loaded, but no correlation between size, of cars and results has been made.

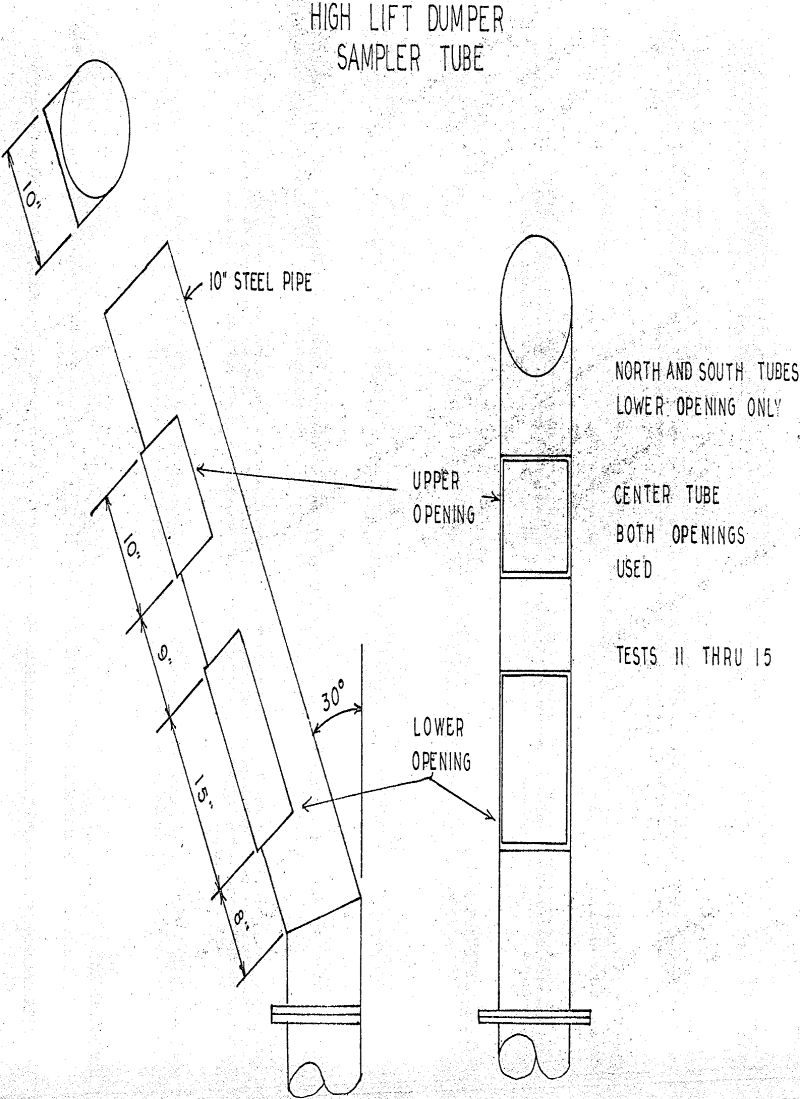

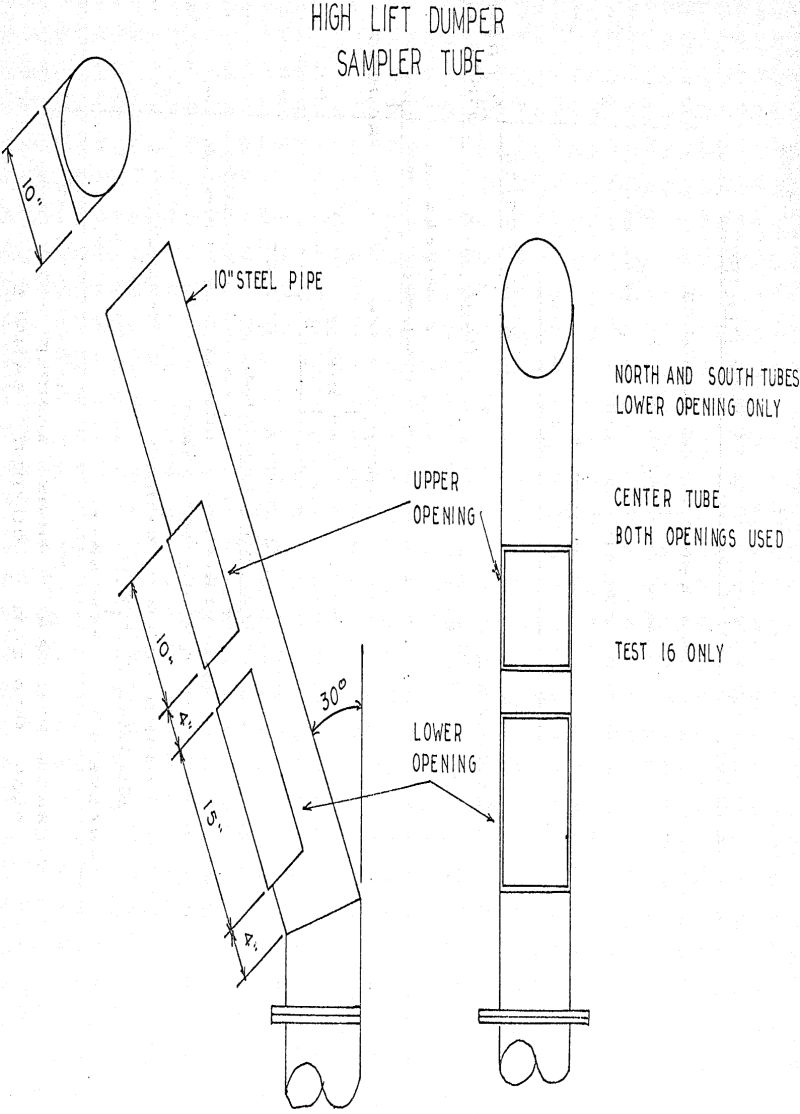

The same cars sampled at the mine were sampled at the dumper. As the car was tipped by the dumper, the openings in the pipe collected the coal sample.

Comparison of Results

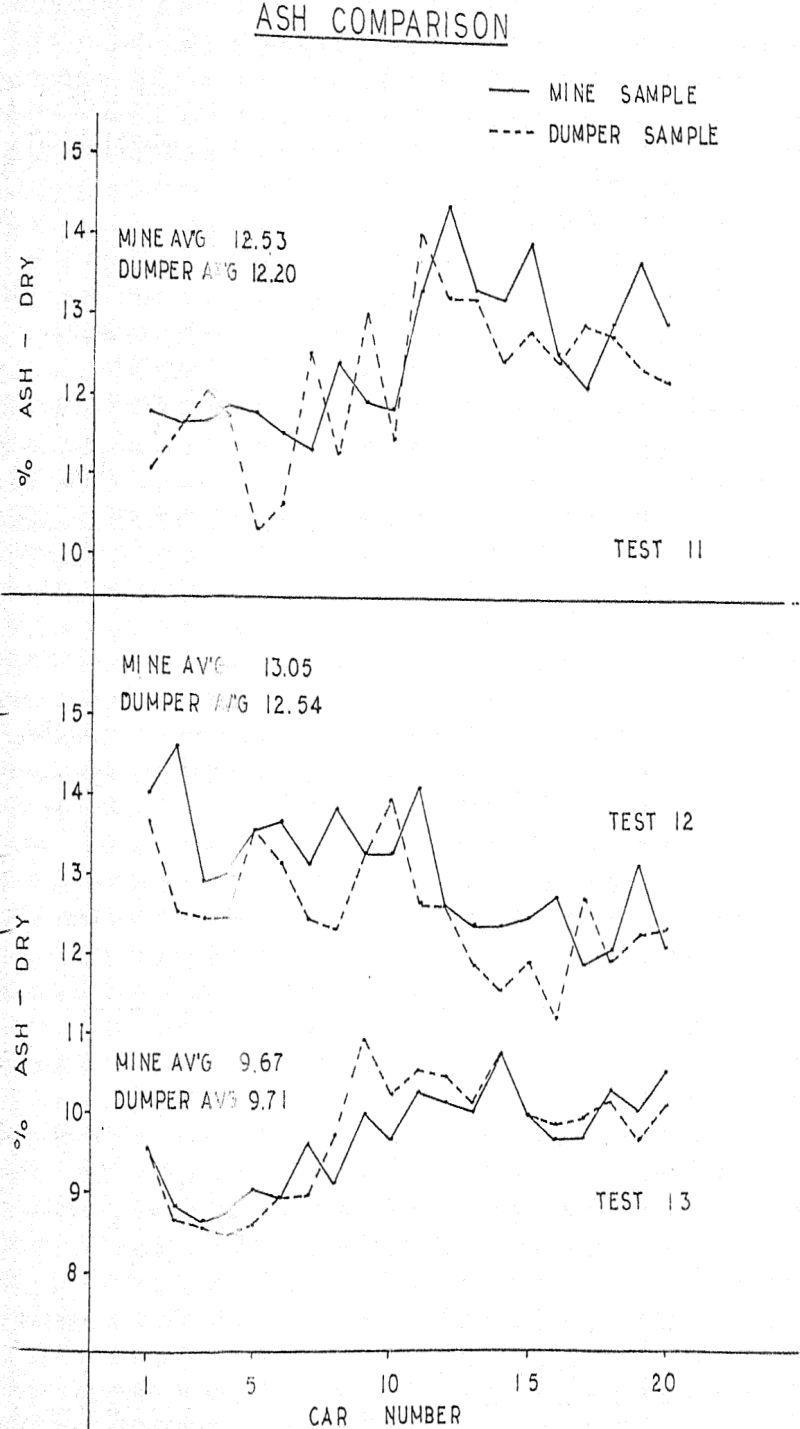

The important fact that was developed by these tests is that this dumper sampling device will reproduce the results of very careful sampling of the same car at its point of loading. Table I outlines the averaged results of the tests made on all of the cars. It does not, however, show how well the dumper sampling device can or cannot follow variations between individual cars.

The charts, Ash and BTU Comparisons show very clearly how well the dumper sampling follows the variations that occurred at the mine. You will note that something happened while loading car number 14, allowing the ash level to go higher and BTU lower than for previous cars. Corrective measures were taken for car 15, so that by the time car 16 was loaded, the ash and BTU were back to the level of earlier cars.

Discussion of Results

Under the standards set up by ASTM D 492-48 we find the minimum criteria for ash that must be met. The following chart shows how well these standards were surpassed for ash.

In all but test No. 14 the variation of ash was less than the requirements for special sampling. Test No. 14 equaled the allowance for commercial sampling.

From these tables it can be easily seen that when the results of tests of a minimum of about 20 cars, or about 1000 tons, are averaged together, the sampling device on the high lift dumper will duplicate the results of careful mine sampling, equal to or well within the limits set forth by ASTM standards. Because the smallest amount that would normally be loaded into a single compartment would be 1000 tons, it is felt that sampling would not be done for less than this amount.

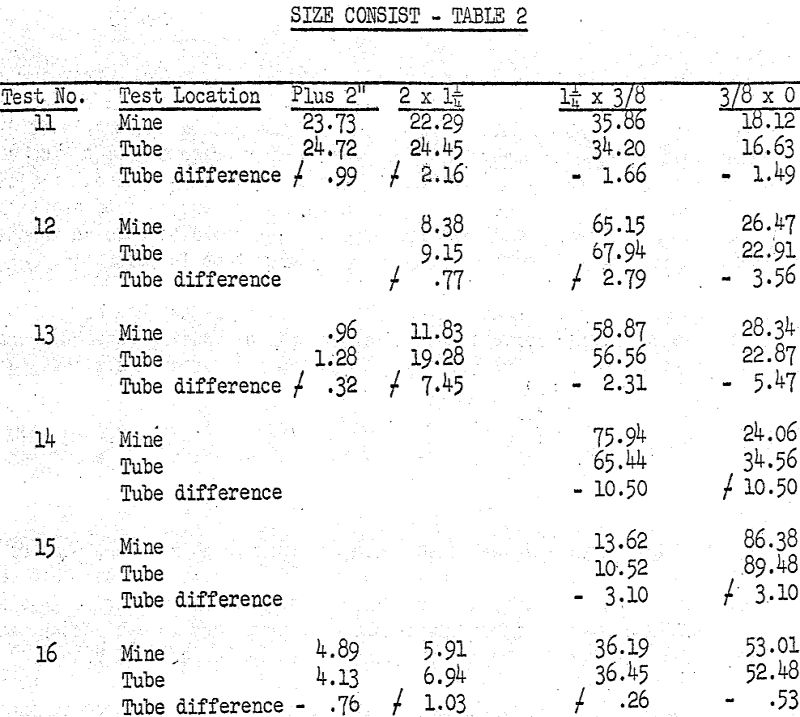

Comparison of size consist to any standard is difficult because there is no factor to which it might be related. During all of these tests, the reproduction, within close limits, of size consist was considered paramount. According to the theory, when the size consist of the sample represents the true consists of the car, the analytical results of the sample should represent the true value of the coal in the car. The harder the coal is to sample because of variations between different size fractions, the more valid this statement becomes.