The accumulation, handling, and utilization of sludges formed from wet process phosphoric acid is one of the major problems in the industry.

The purpose of this paper is to explain some of the considerations and techniques that can be employed to provide some measure of control over the problem.

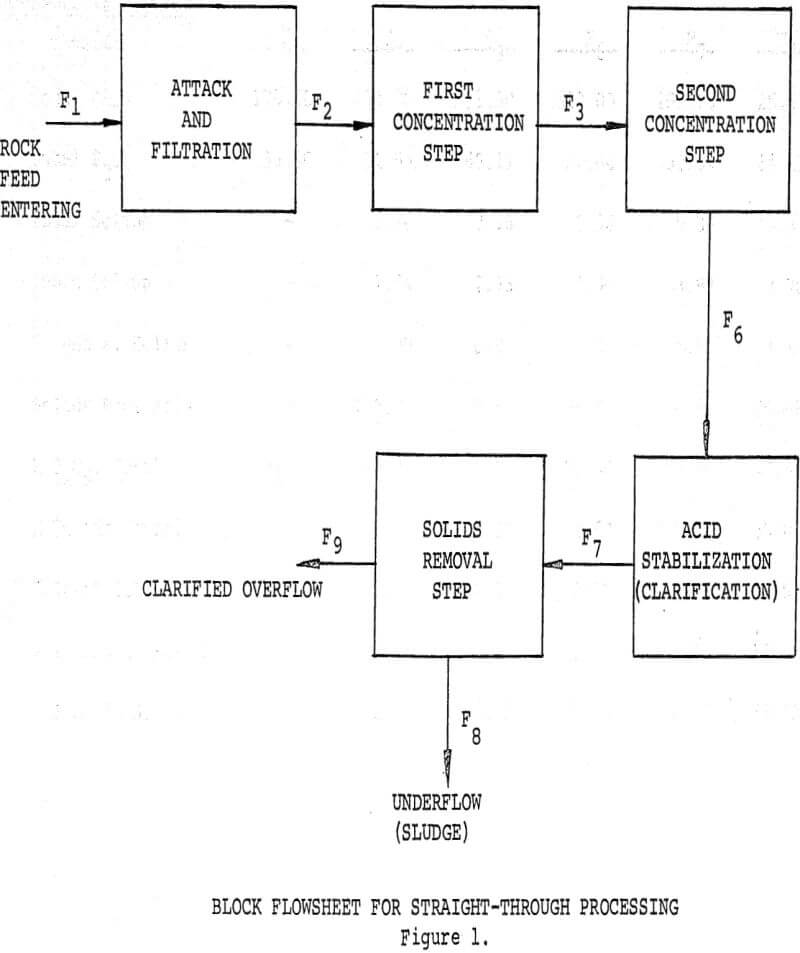

An acid made from a Central Florida phosphate rock is used to illustrate the effects of one process design approach used to provide one type of control. Other approaches or techniques are discussed on a general basis.

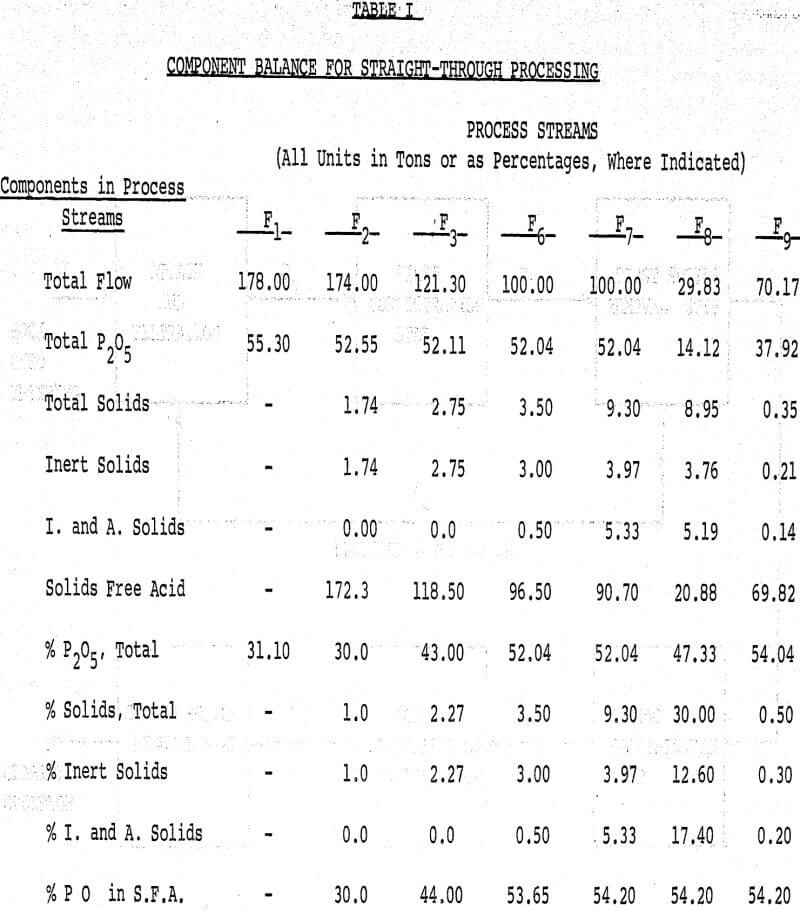

The phosphate rock contains a wide variety of impurities which are completely or partially put into solution in the 30% P2O5 during the attack or reaction step. In the dihydrate process, the solid phase produced during reaction with sulfuric acid is removed by a filtration step. The filtered 30% P2O5 acid contains some small quantity of solids that get through the filter plus a potential for producing additional solids, even when held at the same temperature. This potential is the degree of supersaturation that exists in the acid with respect to the dissolved impurities. The process conditions maintained during attack and filtration directly control the degree of supersaturation existing in the 30% P2O5 at production temperature.

The solids that do not contain solid phase P2O5 are arbitrarily referred to as inerts. These are primarily forms of calcium sulfate, various simple and complex silicofluorides, and in some instances, complex salts containing (AlF6)-³ structures.

The inert solids, by their nature merely depress the P2O5 content as diluents. The end use to which a sludge can be put requires serious consideration of this fact.

The sludge production has been reduced while being upgraded in P2O5 strength; the clarified acid product ion has been increased. The effect on a 1,000 TPD of 100% P2O5 production is considerable in terms of reducing additional process facilities for consuming sludge.

It must be pointed out that process design considerations for this type of processing does not begin and end with a partial clarification step.