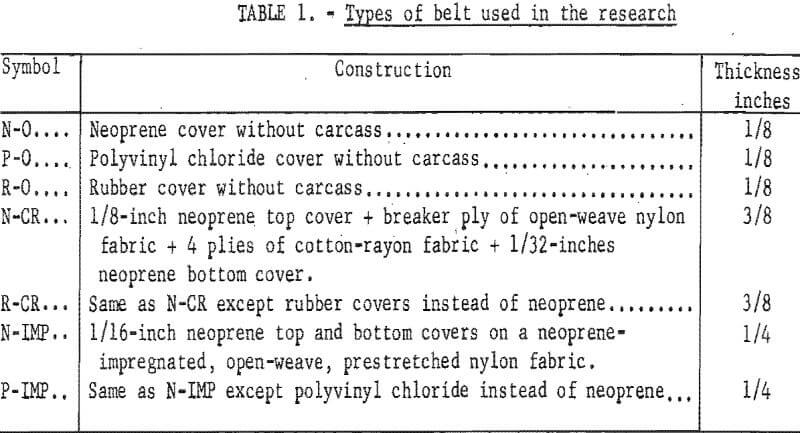

Table of Contents

This investigation showed that neoprene, polyvinyl chloride, and rubber belts ignite readily when subjected to an impinging flame. Although pre-heating of the belt is not necessary for ignition, preheating does increase the probability of developing a self-sustaining flame after ignition. The time and total quantity of heat required to ignite neoprene were greater than those for the other materials. The least time was required for polyvinyl chloride. The total quantity of heat required to ignite polyvinyl chloride and rubber was comparable.

Following ignition, flame propagated on all belts studied. Rates of propagation were highest on rubber belts, no significant difference in rates was observed between neoprene and polyvinyl chloride belts. Velocity of ventilating air current and intensity of ignition source had greater effects on flame propagation than did type of belt. Flame did not propagate in any test using a neutral ventilating condition; that is, without forced draft when the only air movement was caused by heat from the ignition source and the burning belt. When air was forced through the test zone, propagation was more likely to occur in tests with strong rather than weak ignition sources and with high rather than low air velocities. The rate of flame propagation increased with decrease in area of belt entry; it was unaffected by belt width. Water sprays and high-expansion foam were the most effective methods for flame extinguishment studied. Water sprays were most effective when installed as an automatic-sprinkler system between the top and bottom belts with sprays spaced at intervals of 50 feet or less.

Experience has shown that good fire-fighting facilities, clean belt systems, and prompt action by the men in the mine are the best defense against fire. Good fire-fighting facilities would include water-sprinkling systems or high-expansion foam units along belt lines. The fire hazard can be reduced by patrolling belts, inspecting rollers frequently, particularly after the belts have been stopped, and removing dirt build-up on the return idlers and tail sections. Belt conveyors should be installed in neutral entries where practical this not only reduces the chance for flame propagation on the belt, but also reduces the dissemination of float-coal dust. Automatic smoke, heat detecting, and alarm systems would be instrumental in alleviating the hazard of belt fires in coal mines.

A major problem faced by the Experimental Coal miners during these studies was the dense, black, toxic smoke evolved from the burning belts. This problem was particularly serious in the tests on extinguishing belt fires in which visibility was reduced and breathing was difficult. In fighting fires involving belts in an operating mine, respiratory protection is recommended unless all control activities are in fresh air.

The fire hazard of neoprene, polyvinyl chloride, and rubber conveyor belts was studied at the Federal Bureau of Mines Experimental Coal Mine. The effects of intensity of ignition source, velocity of the ventilating air, and type of belt were investigated at three levels in small-scale gallery experiments. Studies were made in the mine on the effects on ignition and flame propagation of belt-entry dimensions, belt widths, and belt configuration. Methods for extinguishing belt fires were also investigated under simulated mining conditions, and during these trials coal dust and grease were placed on the belt.

The research showed that conveyor belts will burn. Neoprene, polyvinyl chloride, and rubber belts, with and without carcass, ignited and propagated flame. The highest rate of flame propagation was obtained on rubber belt. The fire hazard increased with increase in intensity of ignition source and air velocity. Flame propagated only when air was forced through the test zone; propagation was not obtained when forced ventilation was not used, as would exist in a neutral entry in a mine. Automatic water sprays and high-expansion foam effectively arrested flame propagation; direct application of water and bicarbonate dusts was ineffective.

Introduction

Almost 15 percent of all underground coal-mine fires in the United States result from ignition of conveyor belts. In many instances, the fires propagated through thousands of feet of belt entry and caused losses in the

Gallery Tests

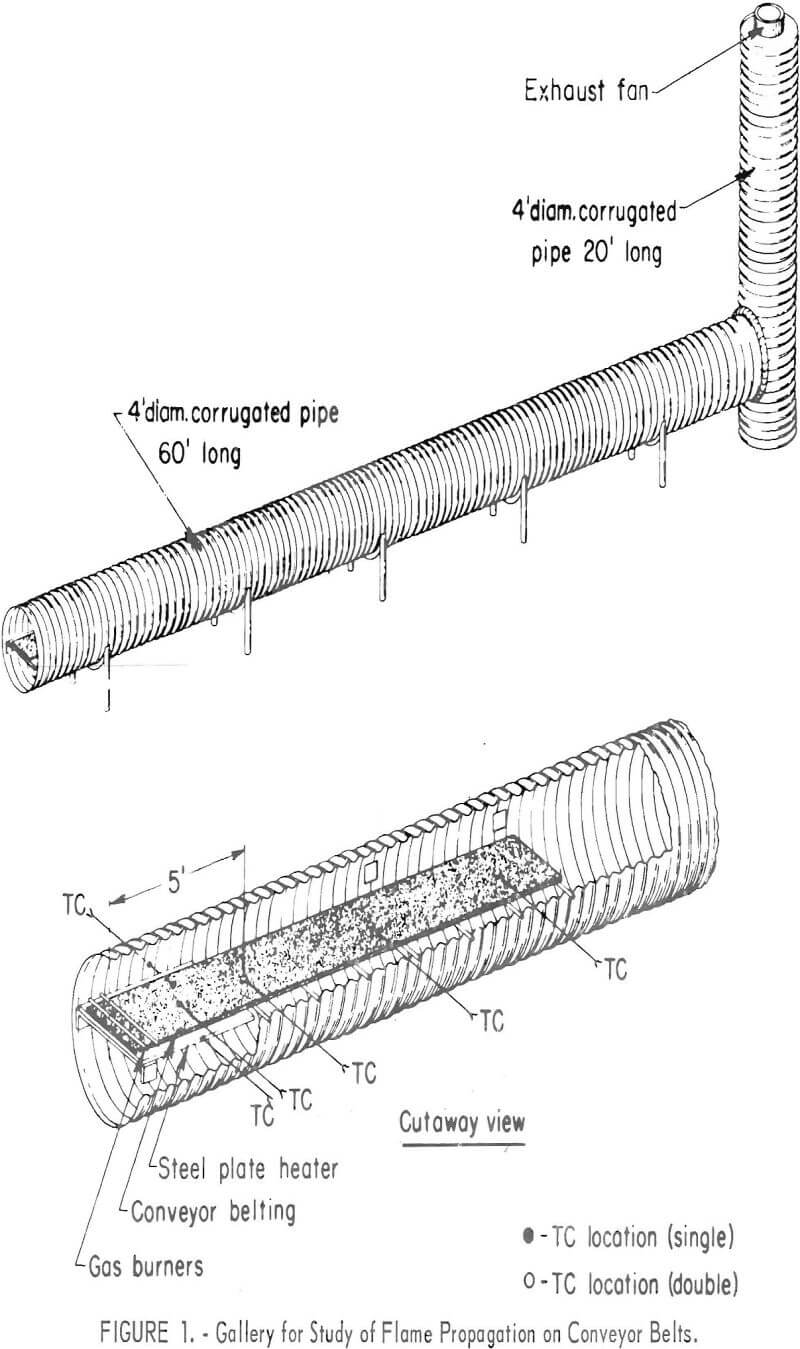

Gallery tests were conducted in the 12-gage corrugated steel duct illustrated in figure 1. This gallery, 60-feet long, with a 20-foot high air stack, was 4 feet in diameter. Ventilating air was provided by a 2-speed exhaust fan mounted on the top of the air stack; air velocity in the gallery was adjusted by louvers controlling secondary air into the vertical air stack.

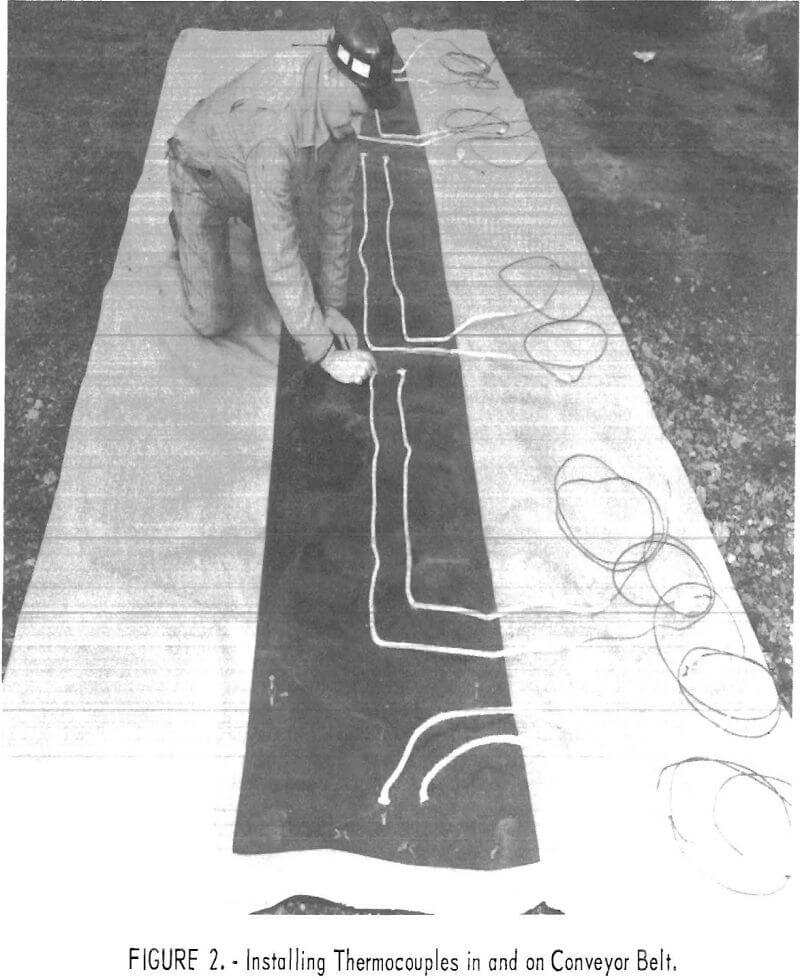

In these experiments, a single 15-foot-long belt section was laid on a 5-foot-long, ¼-inch steel-plate heater; the remaining 10 feet of belt was supported by 5/8-inch-diameter steel rods 1 foot apart. Temperatures above the belt, in the interior of the belt, and at the belt and steel-plate heater junction were measured by Chromel-Alumel thermocouples connected to a 12-point recorder. Thermocouples were attached 1/8-inch above the top surface of the belt and in the interior 1, 2-½, 5, 10, and 14 feet from the front (fig. 2).

Ventilating Conditions

Three ventilating conditions were used in the gallery tests: Neutral condition, Vn, in which airflow was caused by convection currents from the ignition source and burning belt; and V2 and V5 in which the air velocities through the gallery averaged 200 and 500 fpm, respectively. The air-flow in the test zone was measured by anemometer on the belt at its front, midpoint, and end.

Ignition Sources

The following ignition sources were used in the gallery tests:

Source 1 (S1). – Application of heat to bottom of belt and subsequent application of flame to top of preheated belt.

Source 2 (S2). – Simultaneous application of flame (to top) and heat to bottom of belt.

Source 3 (S3). – Application of flame to top of belt.

The flame source (fig. 3) used in the 3 igniting sources consisted of 12 bunsen burners placed in 2 parallel rows of 6 burners each. The first row was 10 inches and the second row was 16 inches from the front edge of the belt. The burners, 6 inches apart in each row and 5 inches above the belt, were angled into the airflow so that flame impinged vertically onto the belt. The propane gas used developed a flame temperature of 2,200° ± 50° F.

In all gallery tests, the first 5 feet of belt rested on the ¼-inch thick steel plate. In tests with sources S1 and S2, the plate was heated by 18, 1,500-watt, electrical-strip heaters attached to the underside. The time required to heat the plate to 450° F was approximately ½ hour.

For source S1, a plate temperature of 450° F was maintained by a control thermostat for 1/4 hour before the gas flame was applied and the airflow established. Plate temperature, gas flame, and airflow were maintained for 1 hour or until flame propagated, whichever occurred first.

For ignition source S2, gas flame was applied, the electrical-strip heaters were energized, and the desired airflow was established simultaneously. The duration of the test was 3 hours unless flame propagation occurred. As discussed later, the maximum temperature in the belt at time of ignition ranged from 70° to 150° F, 10° to 90° above ambient.

For source S3, the gas flame and airflow were established simultaneously. These conditions were maintained for 3 hours or until flame propagated, whichever occurred first.

The heat applied by the steel plate at 450° F to a 30-inch-wide belt averaged 1,300 Btu per minute. The heat liberated by the gas burners was 4,200 Btu per minute. Thus, without considering the heat absorbed by the belt and losses to the air and adjacent material, the heat applied to a belt averaged 5,500 Btu per minute for ignition source S1, 4,800 for S2 , and 4,200 for S3. The intensity of the ignition source is assumed to be proportional to the heat applied.

Preliminary Tests

The effect of width of belt conveyor on flame propagation was studied using the S1 ignition source, the V2 ventilating condition, and single specimens of P-IMP and R-GR belts, 10, 30, and 42 inches wide. The effect of single and parallel belt configurations was studied with P-IMP and N-CR belts, 15 feet long and 30 inches wide, and the S2 ignition source. Single belt configurations were as described under gallery tests; for parallel configurations, the bottom belt was supported on steel rods 9 inches below the top belt.

Mine Tests

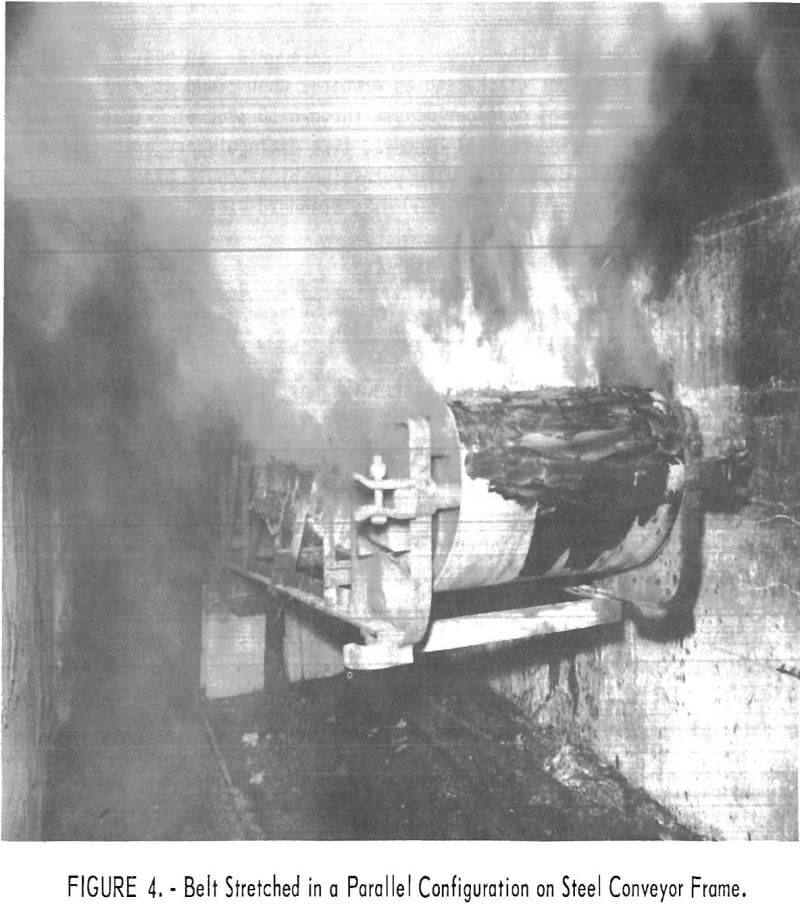

Tests simulating operating-mine conditions were conducted in a 10-foot-wide by 7-foot-high entry in the Experimental Coal Mine. The belt was stretched in a parallel configuration on the 100-foot-long steel conveyor frame shown in figure 4. Most trials were made with 30-inch-wide R-CR belt, and a few trials with N-IMP and P-IMP belts.

The S3 ignition source was used to study flame propagation with respect to belt-entry dimensions and coal-grease accumulations. The simulated coal-grease accumulation consisted of a mixture of 1 pound of Pittsburgh coal dust, 20 percent through a No. 200 sieve, and 5 pounds of grease, having a flashpoint of 375° F and a Saybolt Universal viscosity of 75 seconds at 210° F. This mixture was spread on the first 5 feet of the top belt.

In studies of methods for extinguishing flame, the ignition source consisted of this coal-grease accumulation ignited by flame from a single propane torch.

Fire Fighting

Following belt ignition, fire-fighting operations began when flame was 25 feet beyond the point of ignition. Flame progress was measured by increase in temperature in the interior of the belt, using thermocouples imbedded on 10-foot centers in the top and bottom belts. The fire was considered to be extinguished when additional application of extinguishing agent did not significantly reduce the heat, smoke, or steam generated, and the fire area could be traversed by personnel without special protection or breathing apparatus. All tests except two were conducted with a ventilating velocity of 200 fpm, as measured at a point 50 feet downwind from the belt conveyor; in the two exceptions, the ventilating velocity was 500 fpm.

Water was obtained from a 1-½-inch line connected to the city main; the pH value ranged from 6.4 to 7.2 and the total hardness from 95 to 110 ppm. The static pressure was 70 psig. Water was applied from a nozzle, an automatic sprinkling system, or as high-expansion foam.

The nozzle, 1-½-inch size, was adjustable to form a solid stream, spray, or fog. At a nozzle pressure of 70 psig, a flow of 60 gpm of water was projected as a solid stream 50 feet, as spray 20 feet, and as fog 15 feet.

A simulated automatic sprinkler system was used in 6 tests. The spray heads, connected to ¾-inch pipe, had a 17/64-inch orifice diameter; and, at 60 psig, each sprayed 11 gallons of water per minute in a 75-degree full cone pattern. In two tests, the spray heads were over the top belt on 30- and 60-foot centers measured from the point of ignition; in four tests, the spray heads were between the top and bottom belts on 30-, 50-, 70- and 90- foot centers.

High-expansion foam was used in four experiments. The foam was generated by a commercial unit having a rated free flow of 3,000 cfm and a pressure potential of 0.1-inch water. The foam generator was suspended over the conveyor belt so that the foam discharge was 5 feet from the point of ignition.

Two tests were made with dry potassium bicarbonate. In one, a commercial rock-dust distributor discharged an airborne dust cloud at a rate approximating 80 pounds of dust per minute through 50 feet of 2-inch hose. In the other test, five commercial handheld fire extinguishers each filled with 20 pounds of dust were used. The potassium bicarbonate had a fineness of 82 percent passing through a No. 200 U.S. Standard sieve.

Results

Belt Ignition

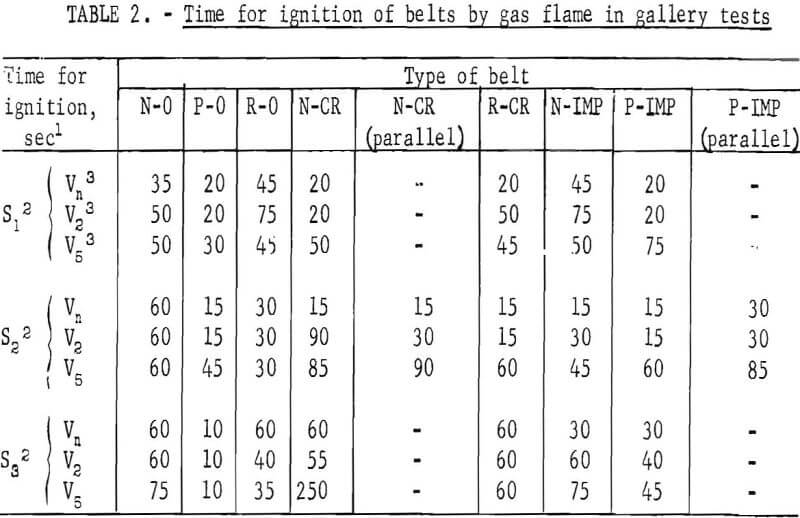

All belts used in the research ignited by gas flame, as evidenced by a marked increase in volume of flame at the burners . Data in tables 2 and 3 show that preheating had no significant effect on belt ignition; ignition occurred only after flame was applied to a belt. Table 2 gives the time between application of the gas flame and ignition. The average time was 45 seconds, ranging from 10 to 250 seconds for P-O and N-CR belts, respectively. Ventilating conditions had a highly significant effect on ignition; the time decreased with decrease in air velocity- The type of belt material had a significant effect on ignition. The time required to ignite neoprene was greater than that for the other materials; the least time was required for polyvinyl chloride. Ignition source, type of carcass, and the use of single or parallel belts had no significant effect on time for ignition.

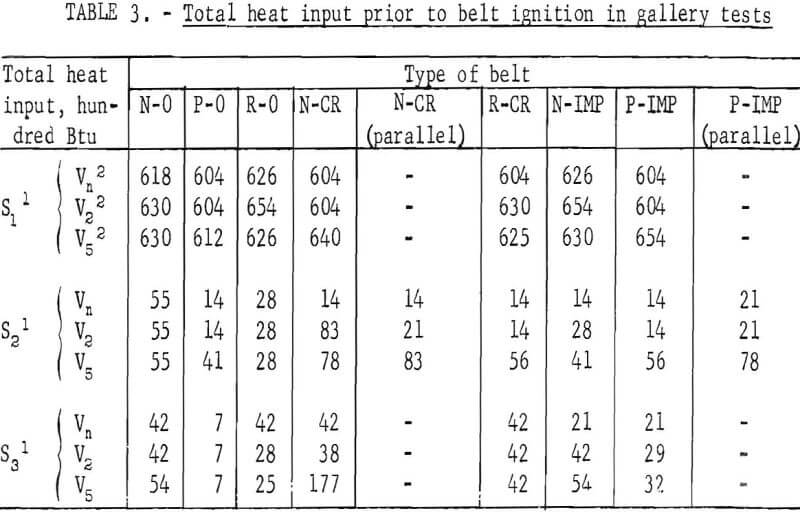

Total heat inputs to belts prior to ignition are given in table 3. These data show that neoprene belts absorbed significantly greater quantities of heat prior to ignition than the other belts, no significant difference was observed between heat inputs to polyvinyl chloride and rubber belts. Air velocity, type of carcass, or the use of single or parallel belts had no significant effect on the total heat input prior to ignition.

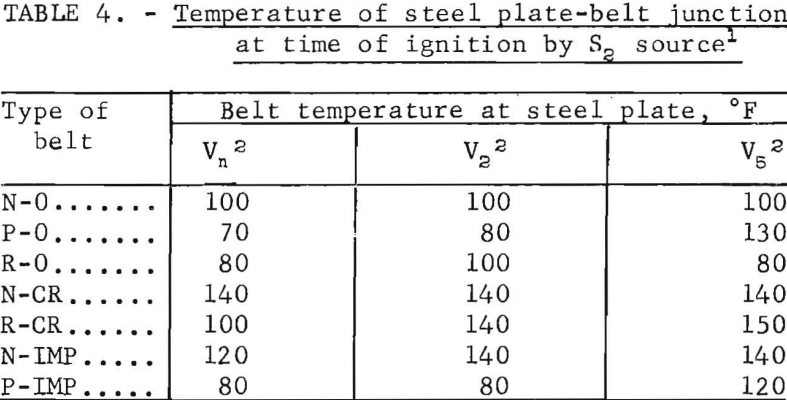

Data in table 4 show that the maximum temperature between the belt and steel-plate heater at time of ignition by source S2 ranged from 70° to 150° F, or only 10° to 90° above ambient. These temperatures are considerably below those developed by source S1 (450° F) , in drum-friction tests (>380° F), and the minimum spontaneous ignition temperatures of similar belts (>750° F in air). Differences between temperatures in table 4 were related more to time for ignition (table 2) than to type of belt or air velocity.

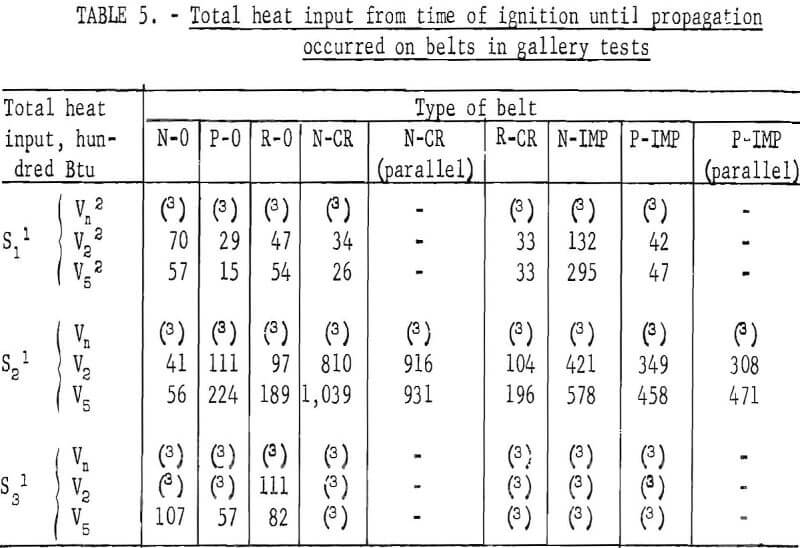

Table 5 shows the total heat input to the belt between the time of ignition and the time the flame traveled 2-½ feet. These data, assumed to be related to the probability of obtaining a self-sustaining flame, indicate that the ventilation condition had a highly significant and preheating a significant effect. Propagation was not obtained in any test with the Vn condition and was less likely to occur with the S3 than with the S1 or S2 sources. No significant difference was observed between the V2 and V5 ventilation conditions, single and parallel belts, belt materials, or type of carcass. However, the limited data indicate that belts with an impregnated carcass required significantly more heat before flame propagated than belts without a carcass.

Flame Propagation

All belts used in the research ignited. Following ignition, flame either propagated the full length of the specimen (propagation) or died out within about 2-½ feet from the ignition zone (nonpropagation).

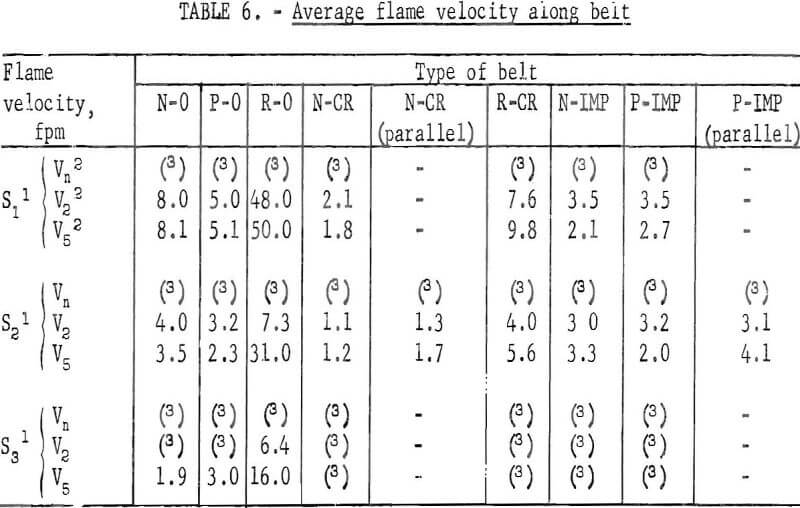

Data in table 6 are the average flame velocities along the belt. Data for the V2 and V5 ventilation conditions show that flame velocity was significantly greater on rubber than on neoprene or polyvinyl chloride belts. No significant difference is observed between flame velocities on neoprene and polyvinyl chloride materials.

A significantly higher flame velocity developed on belts with an impregnated nylon carcass than on the cotton-rayon carcass belts. Flame velocities were generally higher in trials with preheating (ignition source S1) than without; however, the differences were not statistically significant. Significant differences in flame velocities were not observed between the V2 and V5 ventilation or single-parallel belt configurations.

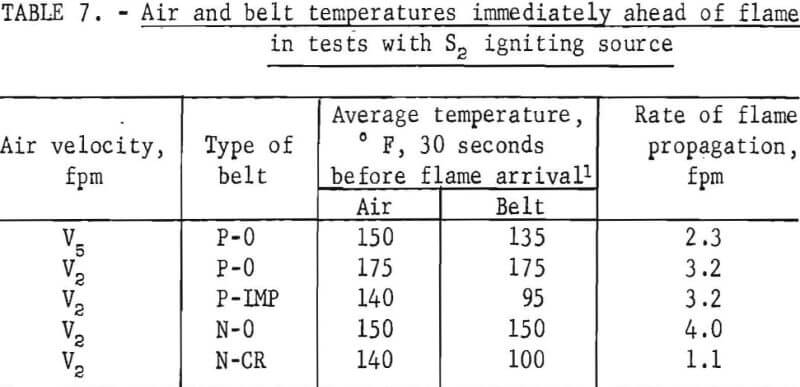

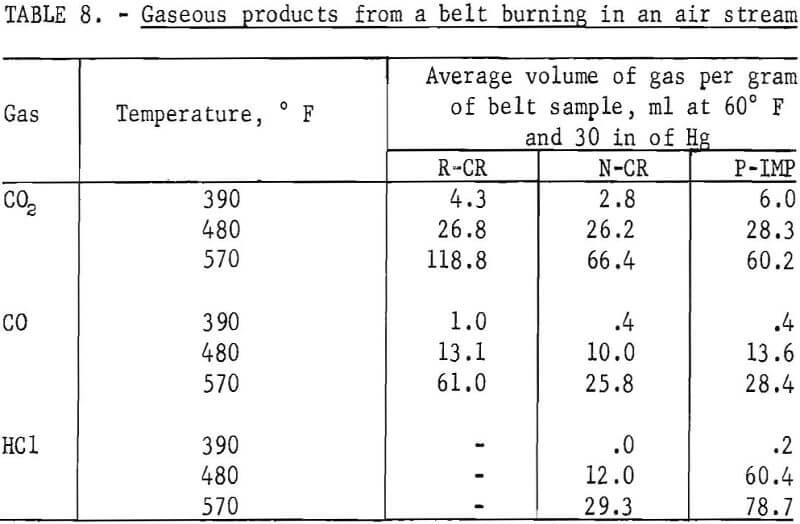

Temperatures taken in the air 1/8-inch above and in the belt 30 seconds before flame arrived were 40° to 125° F above ambient (table 7). These temperatures are considerably below those required to cause decomposition of conveyor belting. Data in table 8 show that the quantity of gaseous products liberated in laboratory tests becomes appreciable only at a temperature of 480° F and higher. Therefore, it may be assumed that little or no decomposition of the belt occurred ahead of the flame.

In the mine tests, flame propagated the entire length of all belts. Comparison of the mine and gallery tests shows that flame velocity decreased with increase in cross-sectional area of the test zone. In tests with R-CR belt and the V2 ventilating condition, the flame velocity was 8 fpm in the 4-foot diameter gallery and 2 fpm in the 10-foot-wide by 7-foot-high mine entry. Coal-grease accumulations on the belt increased the flame velocity by a factor of 2. In gallery tests, flame velocity increased with increase in belt width, being 3-½, 4, and 10 fpm for 10-, 30-, and 42-inch wide P-IMP belt, respectively. However, no significant difference in velocity was observed between 10- and 42-inch widths in the mine tests; the velocity approximated 1 and 2 fpm for P-IMP and R-CR belts, respectively.

Extinguishing Conveyor Belt Fires

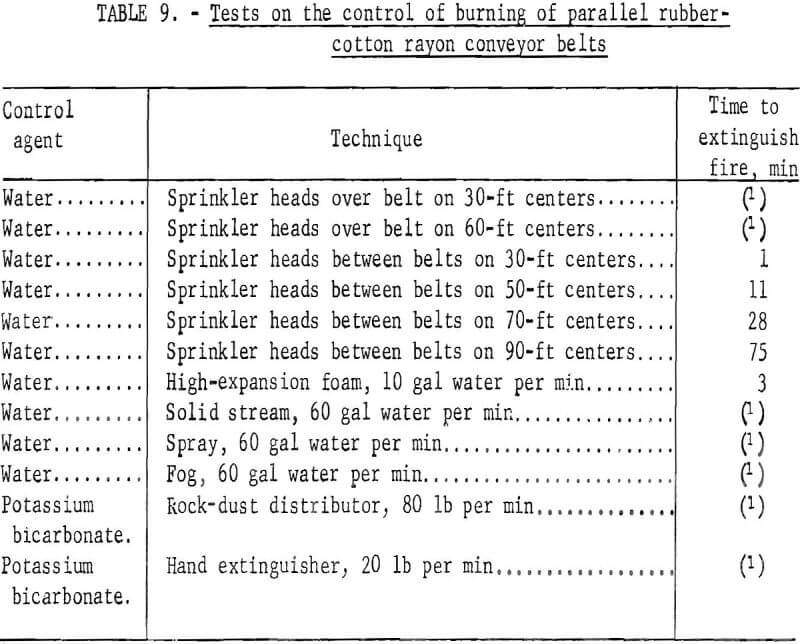

The extinguishing agents and techniques studied were evaluated on the basis of the time required to extinguish burning on both the top and bottom belts. A sprinkler system between belts and high-expansion foam were the only effective techniques of those tried (table 9). Although water from overhead sprinklers, solid streams, sprays, and fog extinguished burning on the top belt, smoke and heat prevented fire fighters from approaching beyond the front of the conveyor to attack the fire on the burning bottom belt. Potassium bicarbonate applied by rock-dust distributor and by hand-extinguishers quenched flame within 5 feet of the point of application, but failed to quench burning downwind. The time for sprinkler systems located between the belts to extinguish burning appears to depend on the spacing between sprays and on the rate of flame propagation. For the rubber (R-CR) belt used in these tests, flame propagated at an average rate of 2 fpm in an air velocity of 200 fpm in the test entry of the Experimental Coal Mine.