Following the wide-spread acceptance of ANFO as a useful, low cost blasting agent, studies have been made to adequately describe the physical and explosive properties of this material. As the quality of the AN blasting prill improved, reliability and sensitivity to initiation were greatly increased and many methods of priming were chosen from the standpoint of economics with little appreciation for the need to initiate so as to obtain the most efficient detonation. Under certain conditions, ANFO could be initiated with primers no more powerful than a No. 8 blasting cap.

It is the nature of ANFO to demonstrate transient velocities upon initiation from any primer or booster. These transients are a function of the primer performance and in order to obtain the most efficient use of ANFO the principles involved in priming should be considered. The principles involve not only power output but also geometry and can be summarized as follows:

A primer or booster for ANFO should have:

- High detonation pressure

- No dual or low order velocity

- Adequate diameter and length

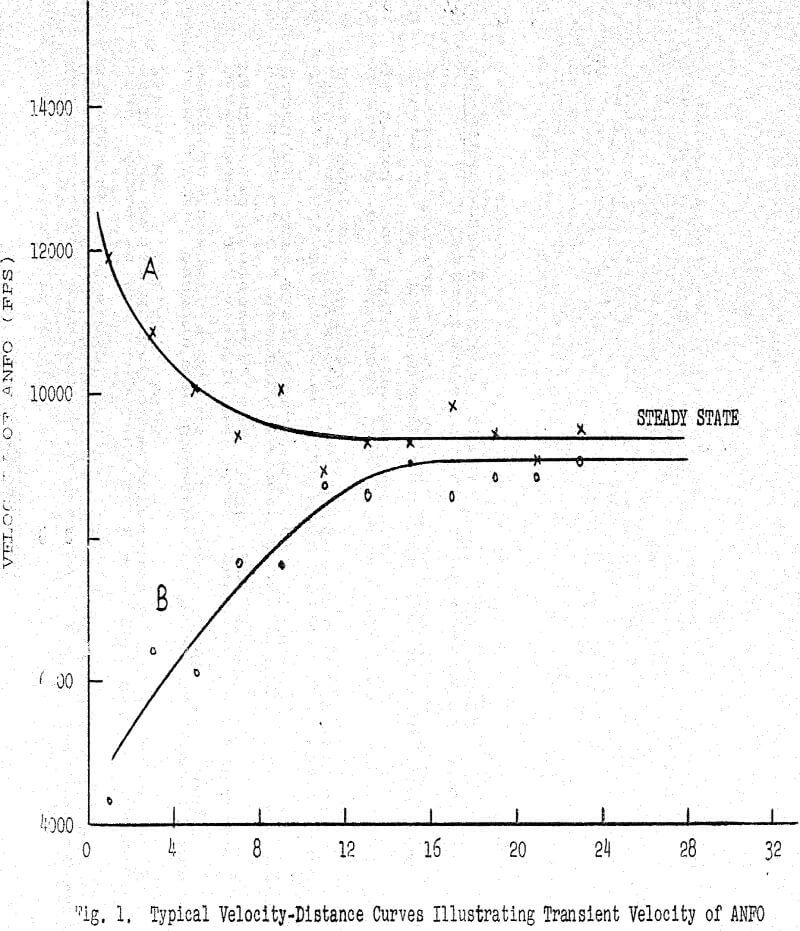

Ammonium nitrate-fuel oil mixtures are extremely susceptable to transient velocities upon initiation from a primer. Initial velocities in ANFO over the range of 2,000 to 20,000 fps have been observed with the streak-camera at the Atlas laboratories. The transient velocity gradually stabilizes as the detonation wave travels along the column until a steady-state velocity condition has been achieved. Terms such as “overdrive”, “underboostering”, “power priming”, etc., have been employed to describe these transient velocities.

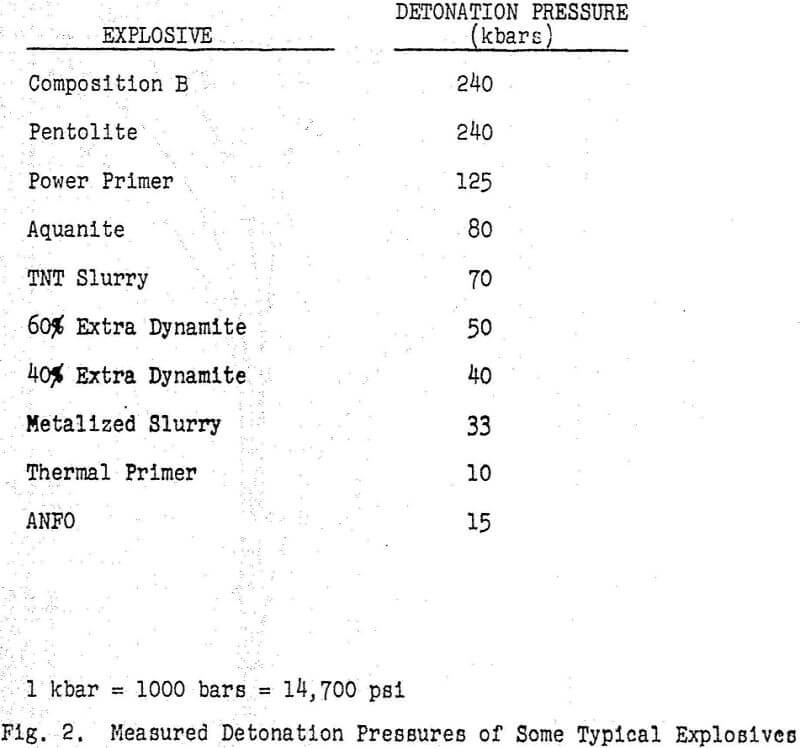

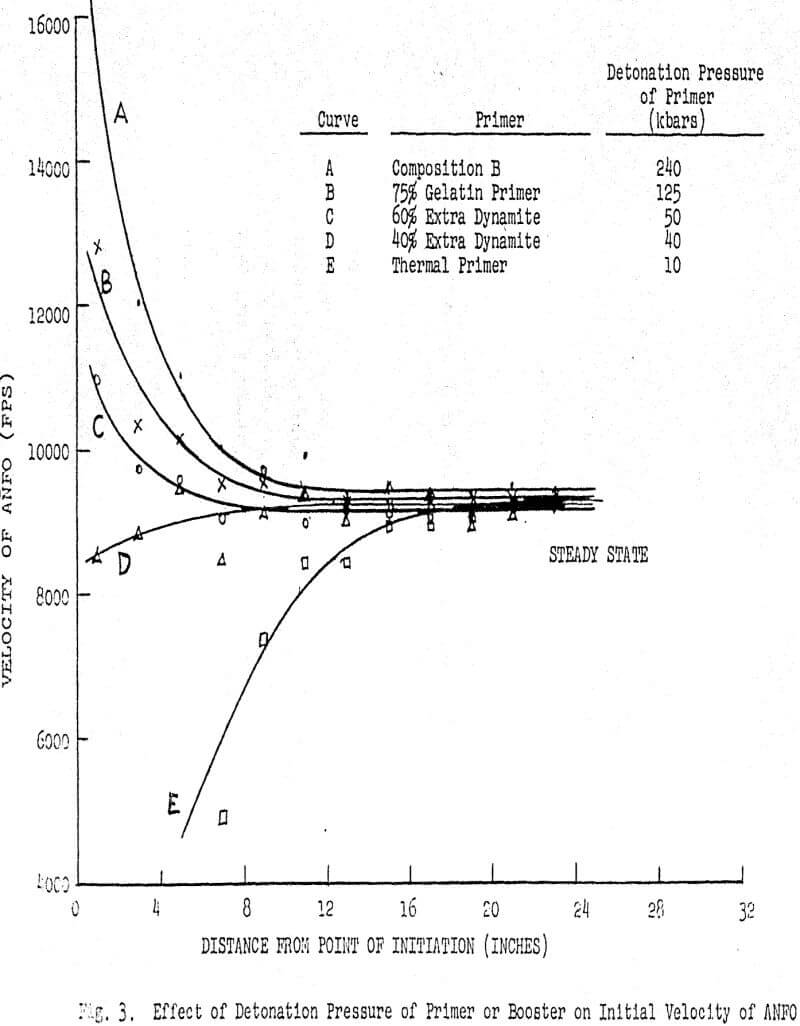

It is a well-known fact that the initiation of any blasting agent is achieved by the transfer of a shock wave from the primer to the receiver. The higher the pressure In this shock wave, the more overdrive will be imparted to the ANFO. Conversely, the lower the pressure, the more inefficient will be the initiation which usually results in an extremely low, transient velocity in the ANFO. Detonation pressure, a measure of the pressure in the shock wave of an explosive, is a property which can be measured in the laboratory.

The explosive performance of a primer or booster is critical to the efficient initiation of a blasting agent. A primer is always detonated with a blasting cap or Primacord, after which it must immediately achieve its highest order velocity and quickly form a stable detonation wave, thus producing its maximum detonation pressure. Some explosives, especially the gelatins and gelatin dynamites exhibit dual velocities and often require a relatively long column length to achieve a steady state detonation velocity.

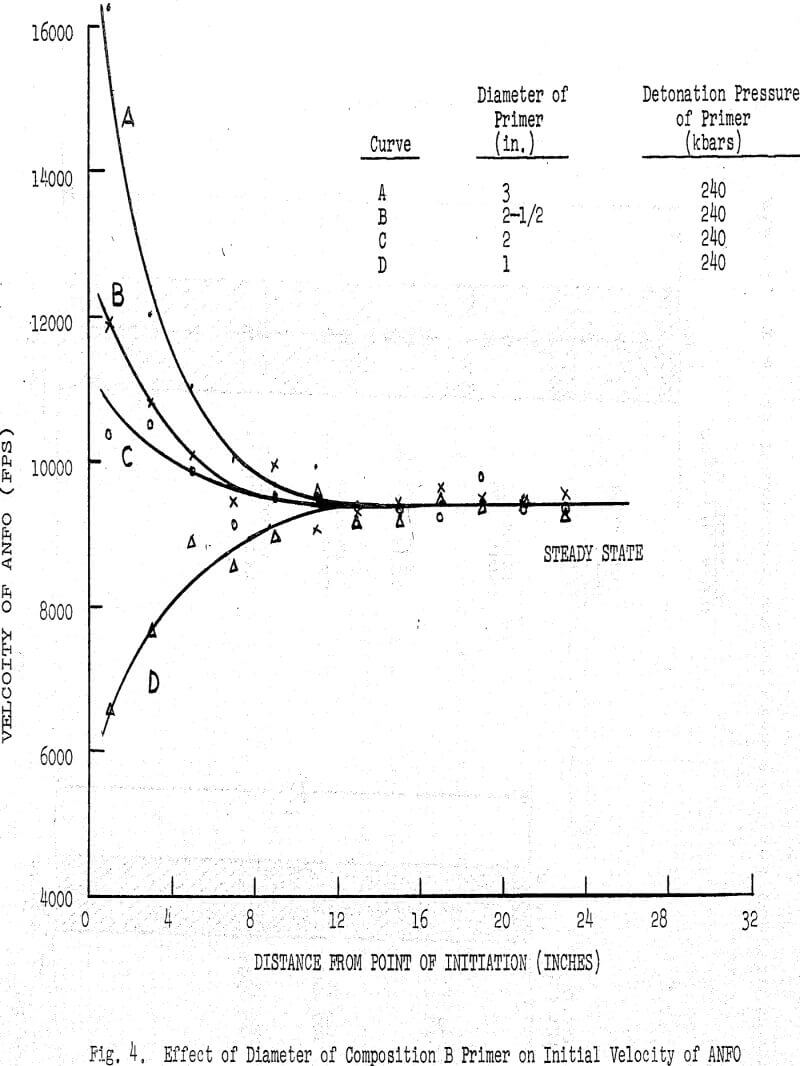

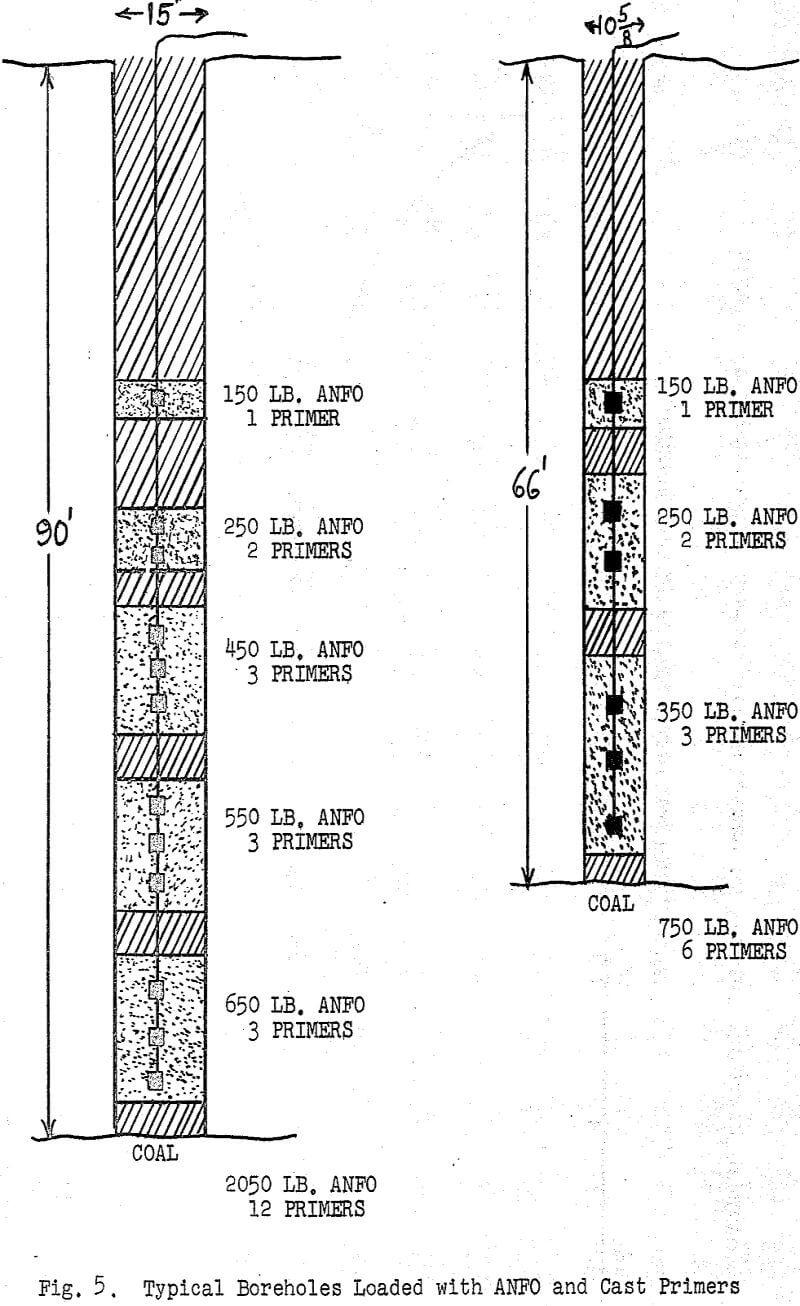

A primer need only be long enough to insure the development of a steady detonation wave. In the large diameter holes, where the economics are more seriously.affected, a length to diameter ratio of one should be maintained. In smaller holes, the usual procedure is to use primers or boosters with lengths which are several times the diameter.

Primers or boosters which fail in any one of the three previously mentioned principles will produce an inefficient initiation in the column of ANFO. The result will be a low order or transient velocity which will persist for some distance up the column. The velocity during this transitional period may be as low as one-third the normal ANFO velocity, resulting in a tremendous loss of energy and in a corresponding loss of pressure which breaks the rock. In the field, poor priming or boostering usually means inability of the ANFO to break or pull the bottom resulting in harder digging and tighter spacings.