Accurate and economic control of line and grade on long tunnels, large structures, excavations and waterways, has been a problem to surveyors and engineers for decades. The conventional method of surveying, incorporating a level, transit, and a number of surveying technicians, has proven, in the past, to be a very expensive and time-consuming operation.

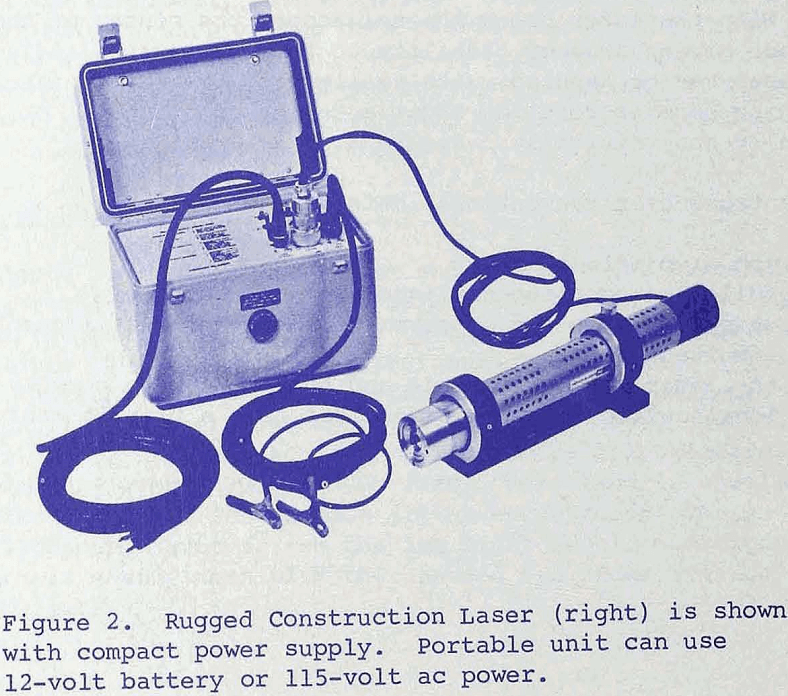

Operation of the laser is extremely simple. The laser head is connected to the power supply, and when “line” and “high voltage” indicator lights blink on (after a thermal relay delay has been 3 energized automatically), the operator merely presses the start control and the laser lights. The Construction Laser is normally supported by an optional laser stand for convenient pointing. Set-up can be done by an unskilled operator in a matter of minutes, and only one man is required.

The laser emits a 0.8 inch-diameter collimated red beam that is centered within the 2.2498-inch outer diameter of the laser housing and is parallel to the mechanical axis of the housing. Beam diameter at 3000 feet is 3 inches. Compact and rugged, it is designed specifically to withstand typical field environments. A metal bellows seal protects the laser’s cavity from dirt and moisture.

Be sure to check our recently updated guide to the best laser engraving machines and what we think are the 3 best laser levels as we did a new update for 2022.

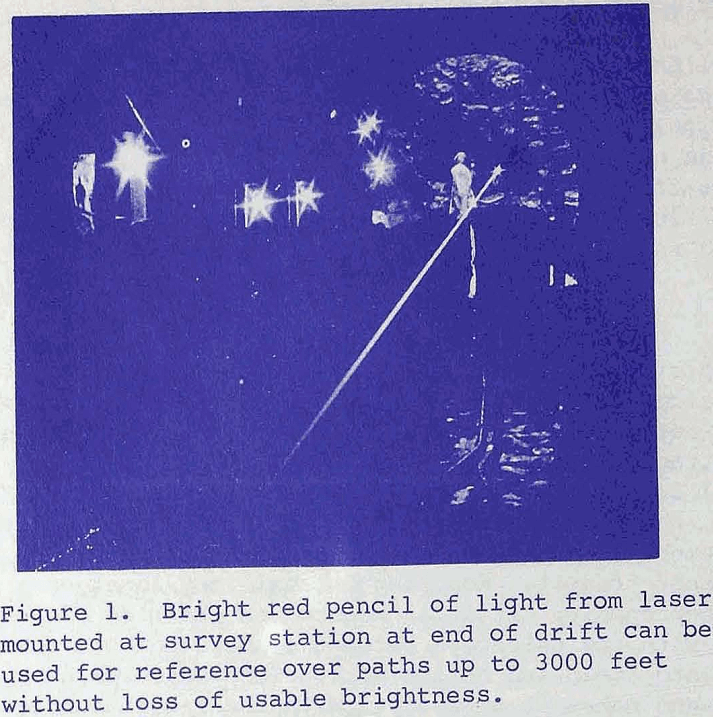

While low in power, its extreme brightness makes it effective for use to distances as great as 3000 feet. At such ranges it can be applied as a reference spotting beam on a working face, used to check the grade of an advance by illuminating the face of a grade rod, or used to guide a continuous mining machine.

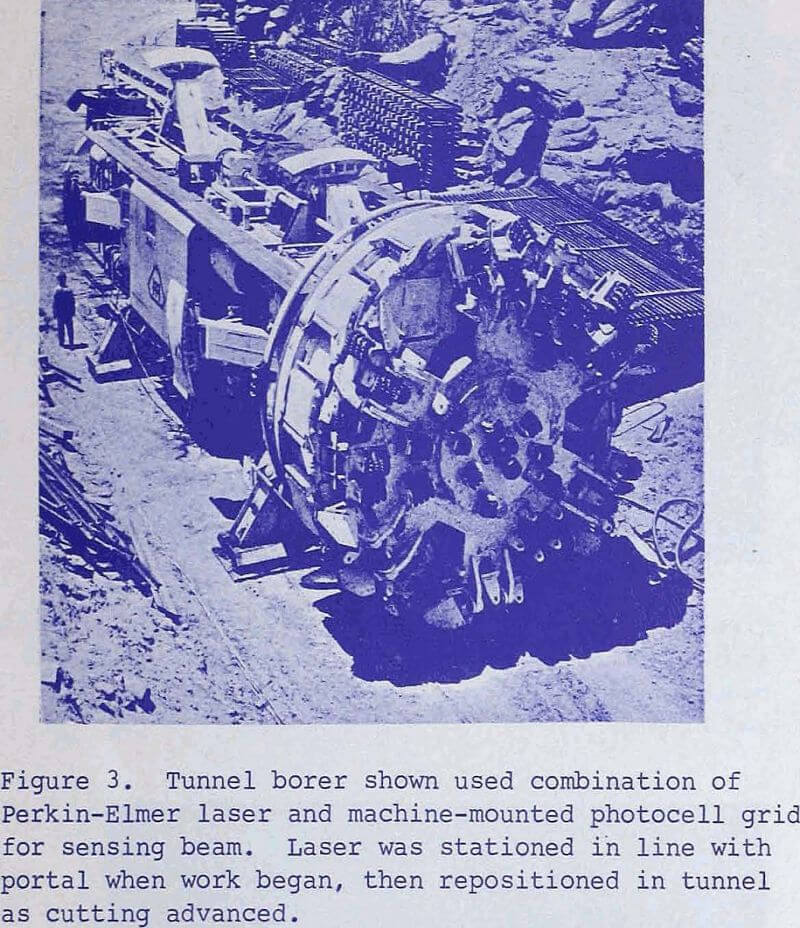

Continuous miner control generally involves a secondary system on which the laser beam is received, namely, photocells or some type of target grid. For automatic operation, the target sensors are automatically intercepted by the moving machinery to control the direction of the machine.

One user of the laser alignment method is saving 10 minutes per round of shooting in tunnel advances by speeding drill hole layout and has cut engineering cost in half by reducing required manpower for instrument work.