Table of Contents

Sound ingots of Zn-Cu-Ti alloys can be semi-continuously cast under appropriate conditions. A modified mold design on a specially constructed, semi-continuous casting stand has permitted casting of ingots having adequate surface quality. With the experimental equipment described, pouring temperatures near 860° F (460° C) produced ingots with better surface quality than when a pouring temperature of 930° F (500° C) was used.

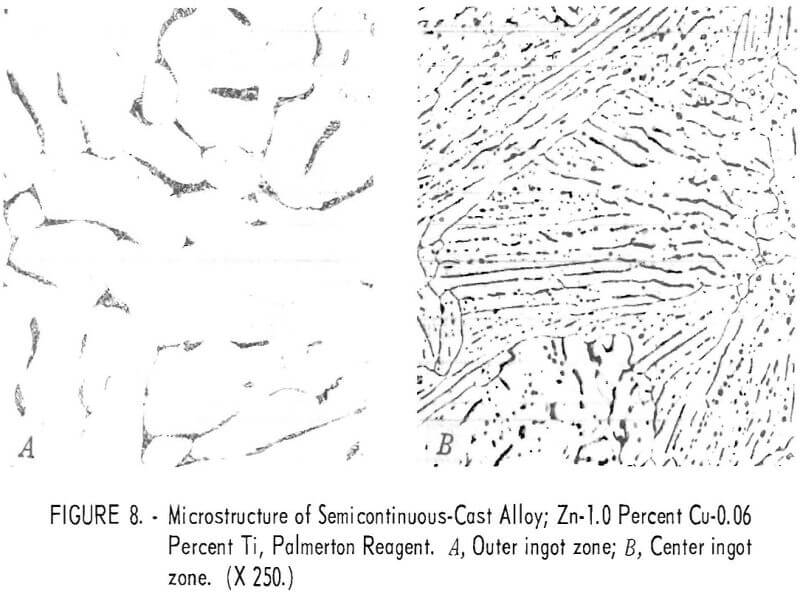

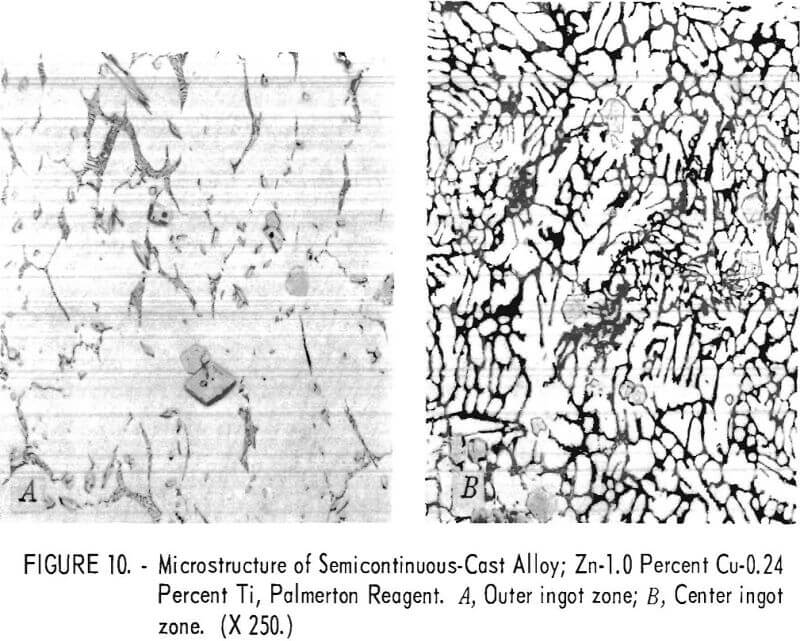

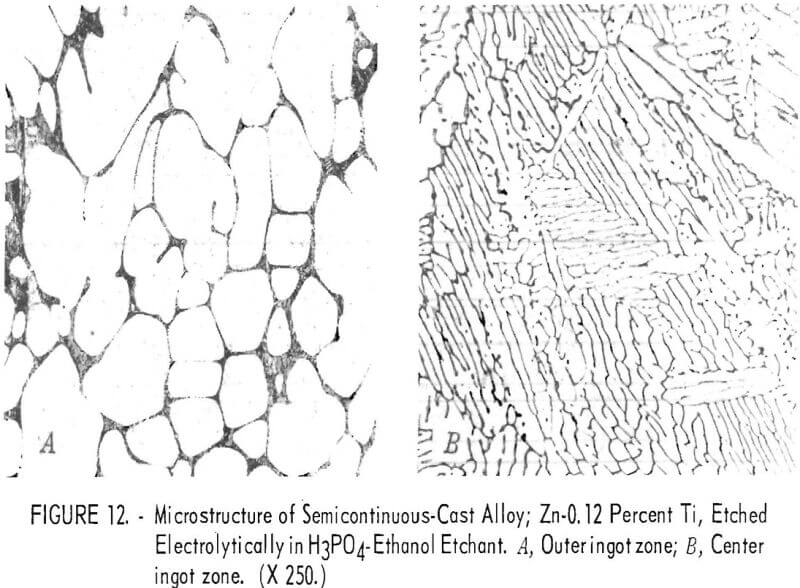

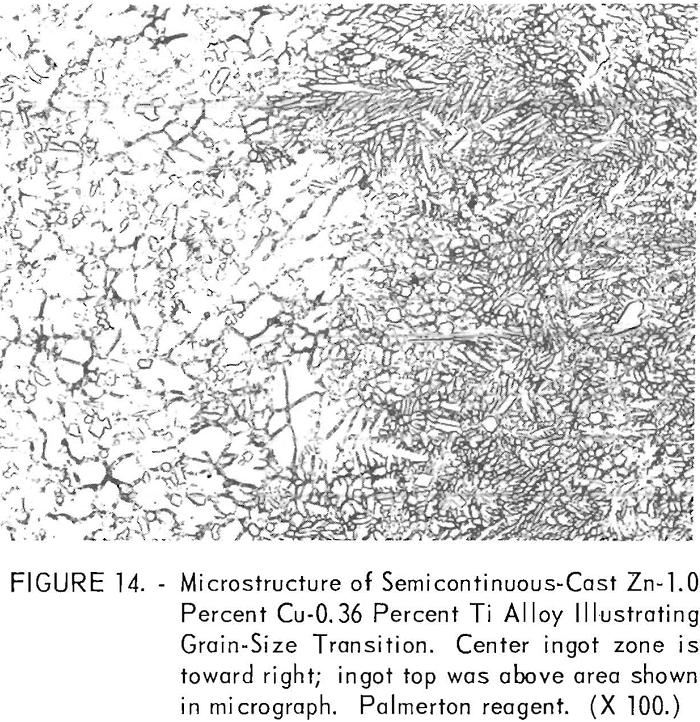

Microscopic examination disclosed the presence of well defined ingot structure, in which there is a grain-size variation from the outer to center ingot zones. The formation of columnar grains near the ingot center was noted in a Zn-1.0 percent Cu alloy, but no columnar grains were observed in the titanium-containing ingots. In the titanium-containing alloys, both the grain size and the interdendritic eutectic structure were finer in the center of the ingots than in the outer ingot zone. In some alloys with titanium, the transition in grain size and eutectic structure between the outer and center ingot zones was quite abrupt. Chemical analyses revealed that the formation of the ingot structure is not related to compositional segregation to any measurable extent.

Comparison of the micro-structures of the semi-continuous-cast ingots with those of small ingots of similar alloys solidified at slow, fast, and intermediate rates confirmed that the ingot structure in the semi-continuous-cast ingots is related to cooling rate; the cooling rate is related to the casting machine design and the influx of cooling water on the solidifying ingot. The center zone of a semi-continuous-cast ingot solidifies at a significantly faster rate than does the outer ingot zone (with the exception of the skin).

Microstructural examination of cross sections of 0.025-inch sheet hot- rolled from slabs of the semicontinuous-cast ingots demonstrated that, with adequate total reduction, the ingot structure does not preclude the rolling of sheet having a uniform microstructure.

Some other interpretations and observations were made from examination of microstructures. In Zn-Ti alloys containing more than about 0.12 percent titanium, primary idiomorphic crystals of TiZn15 compound are formed. The Zn-Ti alloys with considerably more titanium than the eutectic composition still contain substantial quantities of proeutectic crystals of zinc solid solution phase, in addition to the primary idiomorphic crystals of TiZn15 compound and the secondarily crystallized eutectic structure; the same is true for the Zn-Cu-Ti alloys, although the copper additions tend to alter the morphology of the idiomorphic crystals. Quite small titanium additions can produce substantial grain refinement, and the magnitude increases somewhat with increasing titanium content. For a given titanium content, additional grain refinement can occur when the copper content is on the order of 1 percent. Very slow cooling can produce an abnormally large grain size, and tends to change the type of the eutectic structure in titanium-containing alloys from the normal to the anomalous type. It was observed that the degenerate type of eutectic structure can occur when the copper content is increased to 1.5 percent in an alloy containing 0.12 percent titanium, and the alloy is solidified at an intermediate cooling rate.

Hardness surveys of the semicontinuous-cast ingots demonstrated the relationship between hardness and alloy content. The increase in the as-cast hardness resulting from the addition to zinc of 0.3 percent titanium is about two-thirds as great as that resulting when 1 percent copper is added to zinc, without titanium. About the same incremental increase in hardness results when approximately 0.3 percent titanium is added to unalloyed zinc, or to a Zn-1 percent Cu alloy, indicating that the hardening effects produced when copper and titanium are alloyed in cast zinc are primarily only additive, at least for the compositional range studied.

The poor creep resistance of zinc has been an important factor in restricting wider acceptance of wrought zinc alloys for structural applications. It has been shown, however, that a marked improvement in creep resistance can be realized in sheet hot-rolled from zinc alloys containing small additions of copper and titanium. The overall research program of the Bureau of Mines on these promising Zn-Cu-Ti alloys was formulated to encompass extensive testing and evaluation of rolled sheet. It was therefore necessary to devise a convenient and consistent method for the casting of experimental ingots of a suitable configuration to serve as slabs for subsequent rolling.

Pelzel studied the effect of solidification rate on the structure of Zn-Cu-Ti alloys and concluded that ingots cast for rolling slabs should be solidified at the fastest practical rate, such as casting in water-cooled molds, since fast rates result in a desirable finer grain size. The continuous casting process proposed by Ennor and modified by Moritz provides a relatively fast solidification rate; continuous casting has been widely utilized in the aluminum industry. The essential features of this technique have been incorporated into a semicontinuous casting process designed for the laboratory preparation of experimental ingots of zinc alloys. This paper discusses that part of the overall research that deals with evaluating the suitability of the casting procedure for supplying rolling stock for preparation of sheet material for subsequent studies.

Experimental Procedure and Results

Casting Experimental Ingots With the Semi-continuous Casting Machine

Alloys were made containing nominally 1.0 percent (by weight) copper without titanium, and with the same copper content plus 0.03, 0.06, 0.12, 0.18, 0.24, and 0.36 percent titanium; two Zn-Ti alloys containing 0.12 and 0.36 percent titanium were also cast. Only these alloys will be discussed in any detail, although a number of others have also been cast into sound ingots. This is not to imply that every ingot is acceptable; parameters such as cooling water flow must be adjusted experimentally when changing from one to another of the variety of compositions.

Special High Grade zinc, electrolytic copper of 99.99 percent purity, and titanium of 99.6 percent purity were used to prepare the alloys. The copper was added as a Cu-40 percent Zn hardener alloy and the titanium as a hardener alloy of Zn-3 percent Ti. The zinc was melted in clay-graphite crucibles, and the hardener alloys were added and stirred into the melt at about 1,110° F (600° C).

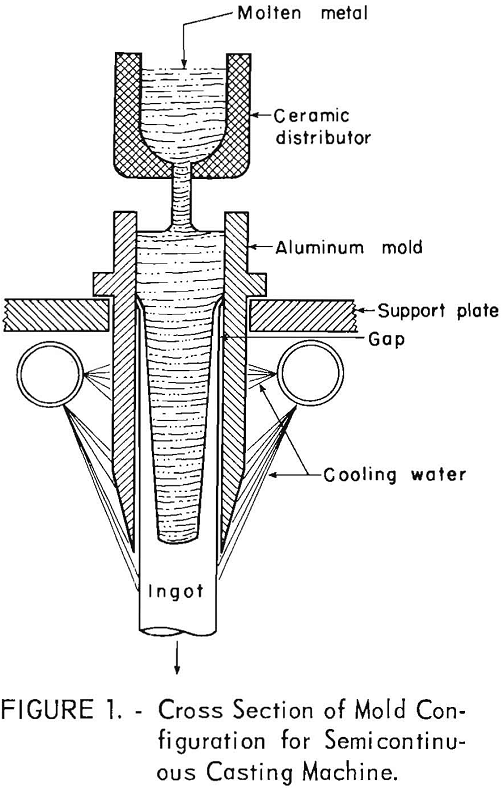

With the semicontinuous casting stand constructed for this work, the molten metal is poured into a ceramic distributor that feeds into a water-cooled

aluminum mold, and water floods the surfaces of the ingots as they are withdrawn from the bottom of the mold (see fig. 1).

Several mold configurations were tried, but the one illustrated in figure 1 proved to be most suitable for the alloys being studied. The inside dimensions of this mold are about 8 inches by 1 inch, and the mold is 4 inches high. The dimensions were selected to provide ingots compatible with the capacity of the available rolling mill.

The particular distinguishing feature of this mold is the extension of the mold wall to well above the horizontal support plate, with no separate refractory mold liner as had been recommended by Moritz as a means of improving ingot quality. In this respect the mold is more akin to that originally proposed by Ennor for the “direct-chill” (DC) process. The experience in the present study with zinc alloys has been that the use of a mold liner introduces a joint where the skin of the partially solidified ingot can be mechanically restricted, resulting in tearing of the skin as the ingot is withdrawn. when such tearing occurs, molten metal escapes, flows into the shrinkage gap, and solidifies as concentric “rippled” regions of metal on top of the previously solidified ingot skin. This is not intended to imply that a mold liner would not be beneficial with a different set of experimental conditions. The extension of the mold wall to well above the horizontal support plate provides for an adequate head of liquid metal. Initially, the inside mold wall was coated with lard oil before each casting, to prevent sticking; however, it was found later that recoating was necessary only for every third or fourth casting.

Regulation of the flow of cooling water for the mold and ingot is important. If the flow is insufficient for complete flooding of the exposed ingot surfaces during withdrawal from the mold, the molten metal in the interior of the partially solidified ingot tends to remelt the surface in localized areas, producing “runouts.” If the water flow is excessive, the gap between the skin and mold wall becomes too great and molten metal overflows into the resultant void. Both conditions can result in intolerable surface quality. About 1-½ gallons per minute was the minimum flow rate adequate for the experimental arrangement.

The rate of ingot withdrawal from the mold was found to be an important parameter of the system, because it determines the extent to which solidification progresses before the cooling water contacts directly the ingot surface. Several rates were tried, but a rate of 6 inches per minute has provided ingots with the most consistently acceptable surface quality for the mold configuration and pouring temperatures employed.

Feeding the mold at a rate matching the withdrawal rate was accomplished by adjusting the diameter of three holes spaced at equal intervals on the long dimension of the distributor bottom (distributors have similar cross section as mold, but are 1-½ inches wide). Distributors were carved from a light-weight refractory firebrick and were coated on the inside surfaces with a whiting solution, they were preheated to about 840° F (450° C) before each casting.

The pouring temperature, taken as the melt temperature just before pouring, was measured with a Chromel-Alumel thermocouple inside a protection tube immersed in the melt. After several melts were poured at 930° F (500° C), it was found that ingots with improved surface quality were produced by pouring near 860° F (460° C), and this lower pouring temperature was then used.

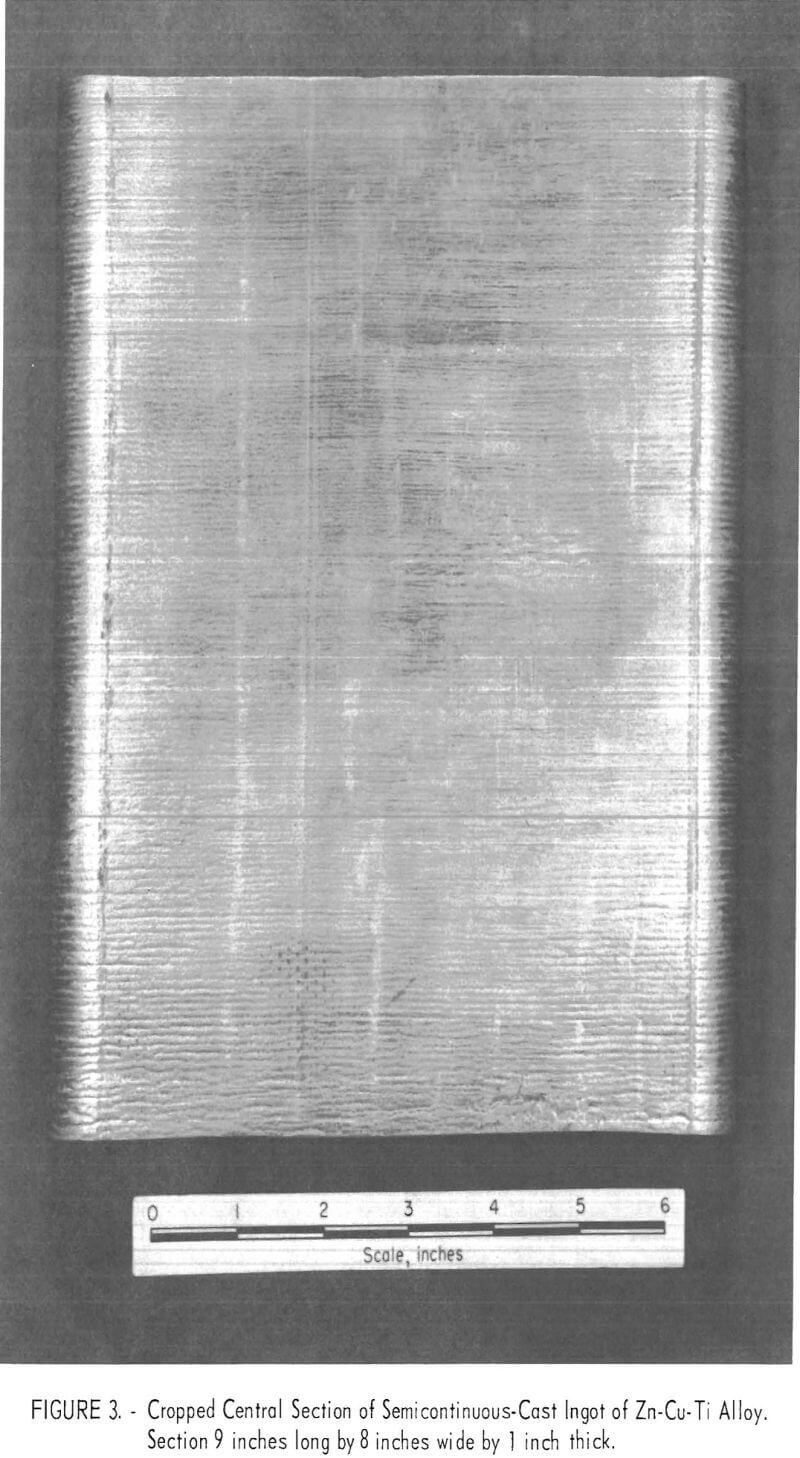

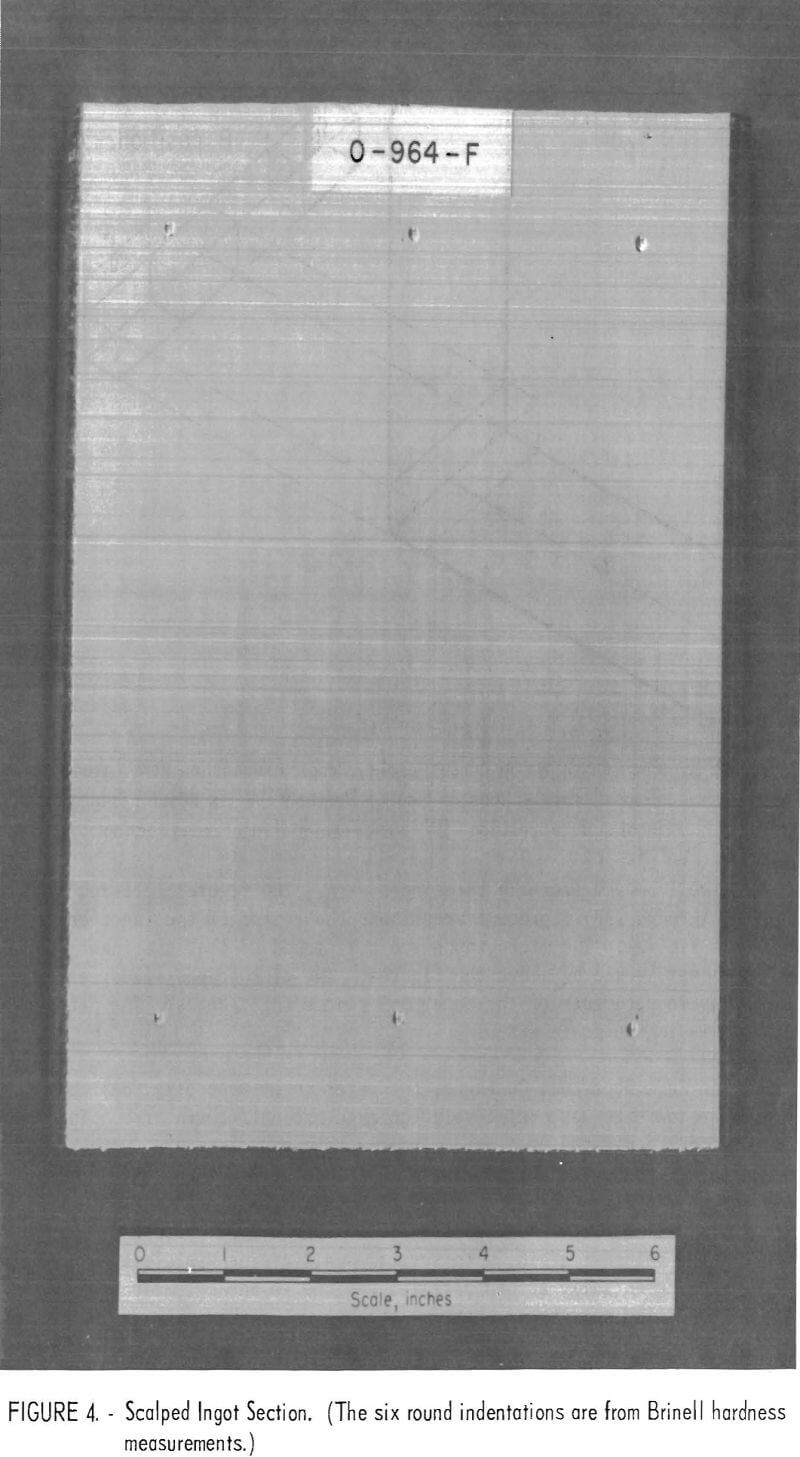

An ingot being cast by the process is shown in figure 2. Casting was stopped when the ingots were about 15 inches long. The top and bottom of each ingot were cropped, to leave 9 inches for rolling stock as shown in figure 3. These central portions of ingots cast by the process are most representative of material cast under continuous conditions. An ingot section is shown in figure 4, after about 0.05 inch was scalped from each rolling surface.

Some additional improvements in the casting process will undoubtedly be made with further experience. As mentioned, the primary goal of the work described in this paper was to obtain sound ingots to serve as slabs for rolling of sheet for subsequent studies; development of a superior casting technique was not a specific objective.

Ingot Microstructure

The ingots were sectioned for microscopic examination as shown in figure 5. The specimens were mounted in a cold-setting resin, were ground, and were polished through abrasives of ¼-micron diamond or Linde B. The etchants and magnifications used are given in the captions under the microstructures of the specimens that are shown in figures 6 through 13; the alloys are identified with nominal compositions.

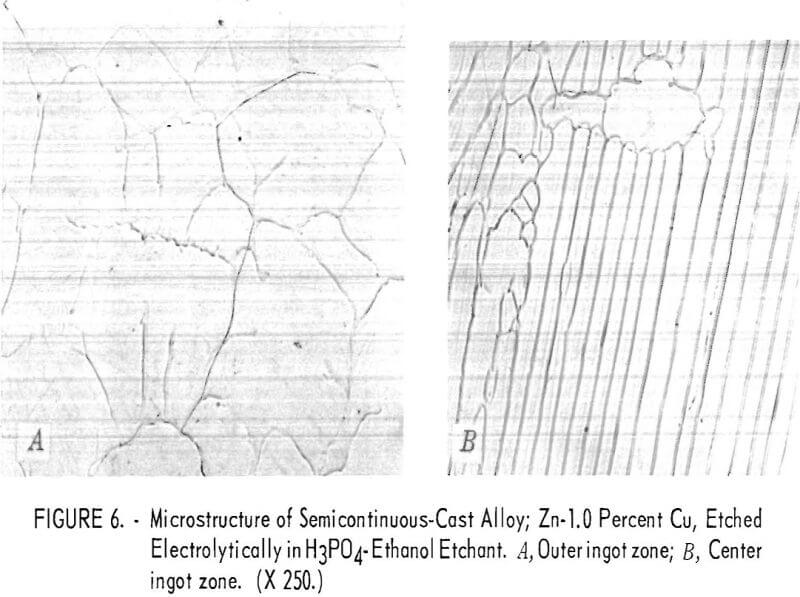

The photomicrographs lettered “A” in figures 6 through 13 were taken of areas corresponding to the structure about 1/8-inch inward from the ingot

![]()

surfaces, well inward from the thin ingot skin. The figures lettered “B” (figs. 6B through 13B) represent areas near the center of the ingot cross sections (see fig. 5). The micrographs are positioned so that the ingot top, the last part cast, would be above the figures. The micrographs illustrate the differences in structure of the outer and center ingot zones. The predominant variation is in the grain size.

In the Zn-1.0 percent Cu ingot, the outer ingot zone (fig. 6A) consisted of cored grains that were relatively equiaxed and uniform in size. The center zone (fig. 6B) consisted of a predominantly columnar structure, with the grains tending to orient toward the ingot top. The center zone contained a number of small grains intermingled with the large columnar grains. The columnar grains displayed a well-defined cellular structure. The microstructure in figure 6B shows a large columnar grain, with several small grains visible toward the top left; the differentially etched parallel regions in the columnar grain accentuate the cellular structure. Careful etching was required to reveal clearly the regions of coring, cellular structure, and grain boundaries. There was no distinct transition in structure between the outer and center zones of this ingot.

![]()

![]()

None of the ingots containing titanium had columnar grains near the ingot centers as formed in the Zn-1.0 percent Cu ingot. In the titanium-containing ingots (figs. 7 through 13), the grain size decreased from the outer to center zones of the ingots, and there was a corresponding decrease in the coarseness of the interdendritic network of eutectic structure toward the center ingot zones. The microstructures illustrate the grain-refining effect of the titanium additions.

Primary idiomorphic crystals appeared in the microstructures of the alloys containing more than 0.12 percent titanium, whether the copper addition was present or not. In the Zn-Ti binary alloys, the idiomorphic crystals are the TiZn15 compound, which has been reported to be the first intermediate phase on the Zn-rich side of the Zn-Ti system. The idiomorphic crystals appearing in the alloys containing copper in addition to titanium are thought to be a modification of the TiZn15 phase; Heine and Zwicker have indicated that some copper may be soluble in the TiZn15 phase. It has also been reported that another intermediate phase (in addition to the TiZn15 and Zn-Cu epsilon phases forms when substantial amounts of copper are added to Zn-Ti alloys containing 0.2 percent titanium, but there was no indication of an additional phase for the compositions investigated in the present study. If the idiomorphic crystals observed in these Zn-Cu-Ti alloys are a modification of the TiZn15, phase, then this same phase should also be a constituent phase in the interdendritic eutectic structure, along with the light-etching, zinc solid solution phase. Recently, the Zn-Ti eutectic composition and temperature have been established as about 0.19 weight-percent titanium and 418.6° C (786° F) ; results of earlier investigations of the eutectic composition ranged from 0.12 to 0.45 weight-percent titanium.

The change in microstructure from the outer to center zones in some ingots was quite abrupt. An example of the transition zone is shown in figure 14. This photomicrograph at X 100 was taken of an area between the two zones of the specimen depicted in figures 11A and 11B.

Ingot sections were etched and macrostructures were examined, but variations in the macrostructures within given ingots or between different ingots were not evident to a degree warranting photographic illustration.

Chemical Analysis

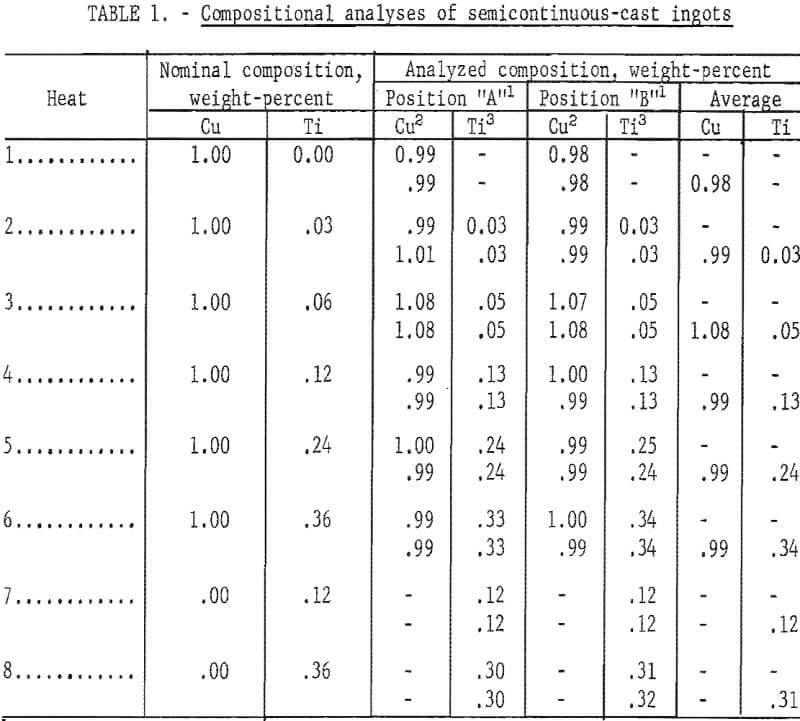

In order to check on the possibility of compositional segregation from outer to center zones of the ingots, samples for chemical analysis were

sectioned at equivalent positions in the ingots to where the microstructures were studied. The individual and average results, shown in table 1, revealed no significant segregation effects between the outer and center ingot zones.

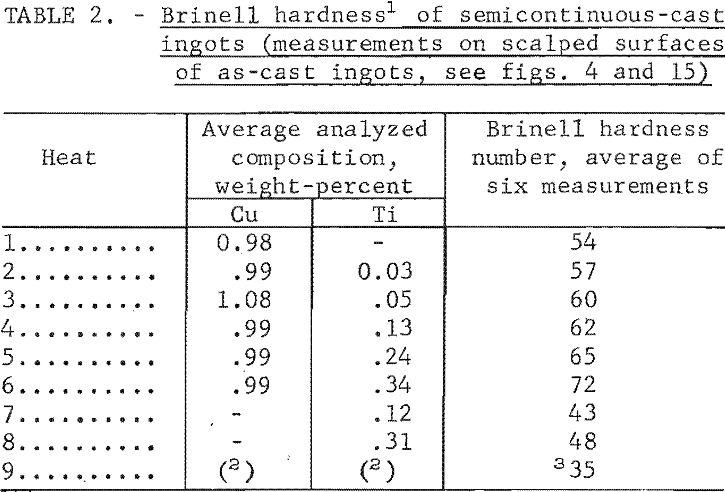

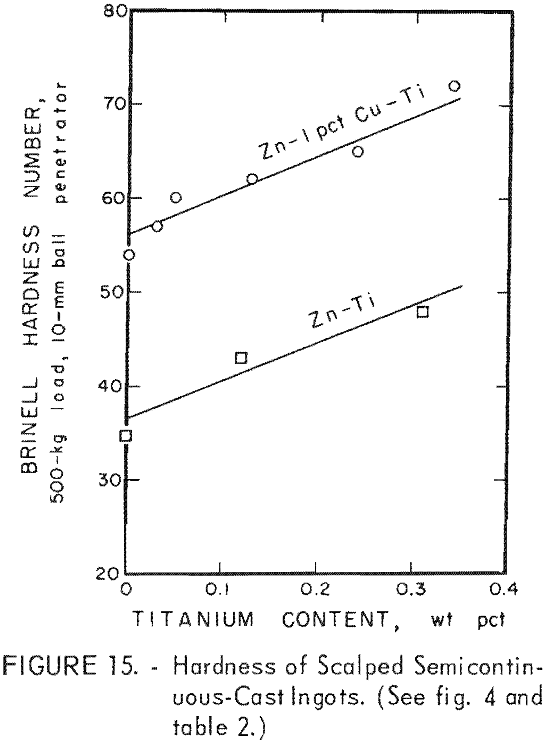

Ingot Hardness

The as-cast hardness was determined on the scalped surface of each ingot. For comparison, hardness measurements were also made on an ingot of unalloyed zinc that was cast and scalped similarly to the other ingots. The hardness indentations were made in the six positions shown in figure 4, except that four additional measurements were made for the unalloyed zinc. The values represent the hardness of the outer ingot zone. There was, in general, good agreement between the measurements made in the different positions on each ingot. The average hardness values are shown in table 2, and are plotted graphically in figure 15 to show the variation in hardness with titanium content for the series both with and without the nominal addition of 1 percent copper. The increase in hardness resulting from the addition to zinc of 0.3 percent titanium is approximately two-thirds of that resulting when 1 percent copper is alloyed in cast zinc. Roughly the same incremental increase in hardness results when about 0.3 percent titanium is added to unalloyed zinc or to the Zn-1.0 percent Cu alloy, indicating that copper and titanium have primarily only additive hardening effects in cast zinc, at least for the compositional range studied. If any enhancement of hardening can be realized from interaction of the two alloying elements, it must be brought, about by additional treatment.

Solidification Rate Experiments

The variation in microstructure from the outer to the center zones of each ingot was considered to result from appreciably different cooling rates occurring in the casting process. Chemical analysis had revealed that compositional segregation was not a factor, and Pelzel and Piotrowski have noted that the microstructure of Zn-Ti alloys is sensitive to cooling rate.

The casting process used to prepare the ingots is such that two distinct freezing rates are encountered. Once continuous conditions are established, the molten metal in the mold freezes a skin. As solidification progresses, the skin then shrinks away from the mold, providing an insulating air gap (fig. 1) that reduces the rate of heat removal from the partially solidified ingot. As the ingot is withdrawn downward, solidification of the outer ingot zone proceeds at a relatively slow rate until the leading portion of the ingot approaches and moves below the mold “skirt.” At this point, the rate that heat is removed from the ingot is controlled by the influx of cooling water in direct contact with the ingot surface. The interior of the ingot extending outward from the center of the 1-inch, thick cross section is consequently cooled and solidified at a much faster rate than was the outer zone of the ingot (except for the skin, which solidifies quite rapidly also).

In order to relate the microstruetures observed in the semicontinuous-cast ingots more closely with cooling rate, three series of small alloy specimens were cooled and solidified at three cooling rates ranging from very slow to quite rapid.

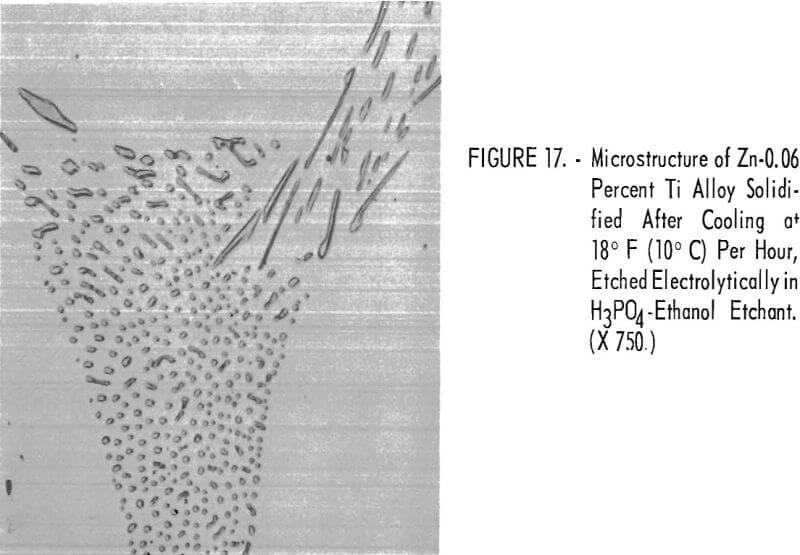

One series of Zn-Ti alloys containing nominally from 0.06 to 0.36 percent titanium was melted in high-purity alumina boats under a purified helium atmosphere and was cooled to below the solidification temperature, from 1,020° to 770° F (550° to 410° C), at about 18° F (10° C) per hour.

Microstructures of four of these alloys are shown at x 50 in figure 16. The very large grain size of these small ingots compared with that of the semicontinuous-cast ingots (figs. 7 through 13) is immediately evident. The form of the eutectic mixture of the Zn-0.06 percent Ti alloy is illustrated at higher magnification in figure 17. The photomicrographs were taken of areas near the centers of these small, slowly cooled ingots, and the structures shown are typical of the overall structures, except for the immediate surface areas.

In figure 16A (and fig. 17), the primary dendrites of zinc solid solution (light etching) are surrounded by the interdendritic eutectic network of TiZn15 plus zinc solid solution. The eutectic structure appears to have

characteristics of both the normal and anomalous types of eutectic structure, and apparently represents a condition intermediate between the two types. The eutectic structures appearing in the microstructures of the other alloys (figs. 16B through 16D) are more nearly of the anomalous type; the morphology

of the eutectically formed TiZn15 phase approaches the morphology of the pro-eutectically formed, primary idiomorphic crystals of TiZn15, such as appear in figures 16C and 16D.

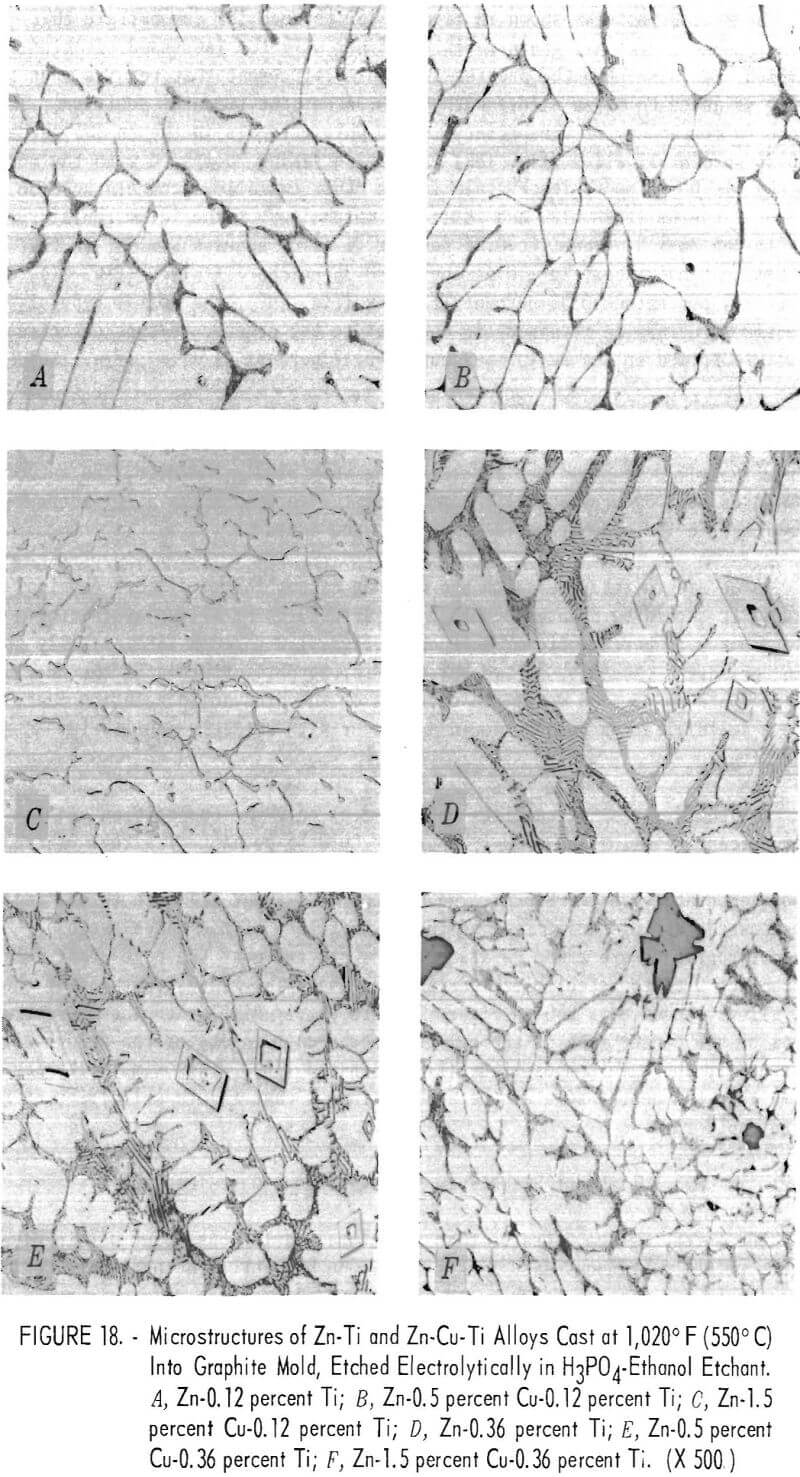

A second series consisting of two Zn-Ti and four Zn-Cu-Ti alloys was cast at 1,020° F (550° C) into a 1-inch diameter graphite mold. The two Zn-Ti alloys contained 0.12 and 0.36 percent titanium; the four Zn-Cu-Ti alloys consisted of an addition of 0.5 and 1.5 percent copper for each titanium level. The graphite mold was gated and was preheated to 200° to 230° F (93° to 110° C) before each casting.

Microstructures of the six alloys are shown in figure 18, for center ingot areas representing sections parallel to the mold axis. These micrographs at x 500 show the contrast in structure between these alloys and those of the slowly cooled alloys shown at x 50 in figure 16. The grain size of the specimens depicted in figure 18 is approximately 10 times smaller than that of the specimens shown in figure 16, a result of the much different cooling rates. Comparison of the microstructures in figure 18 with those in figures 7A through 13A shows that the grain sizes are not too dissimilar, taking into consideration the difference in magnification. This indicates that the solidification rate of the alloys in the graphite mold was on the same order as that of the semicontinuous-cast ingots toward the outer ingot zone.

The microstructures of the alloys in figures 18A through 18C show that the addition of 1.5 percent copper in the alloy containing 0.12 percent titanium produces some grain refinement. The eutectic structures in the Zn-0.12 percent Ti (fig. 18A) and Zn-0.5 percent Cu-0.12 percent Ti (fig. 18B) alloys appear normal, but the eutectic structure in the Zn-1.5 percent Cu-0.12 per-cent Ti alloy (fig. 18C) is apparently of the degenerate type, with the TiZn15 phase (probably modified by the copper addition) forming as the divorced eutectic.

The microstructures shown in figures 18D through 18F demonstrate that there is some additional grain-refining effect with the increased titanium addition, and also show the progressive grain refinement that results when the copper is added to these alloys with the 0.36 percent titanium addition. The change in morphology of the primary idiomorphic crystals in the Zn-1.5 percent Cu-0.36 percent Ti alloy (fig. 18F) is quite striking, compared with the morphology of the idiomorphie crystals in the other two alloys containing 0.36 percent titanium (figs. 18D and 18E); the morphology of the idiomorphic crystals in the Zn-1.5 percent Cu-0.36 percent Ti alloy appears similar to that in the semicontinuous-cast Zn-1.0 percent Cu-0.36 percent Ti alloy (fig. 11). In the Zn-1.5 percent Cu-0.36 percent Ti alloy (fig. 18F), the normal type of eutectic structure is retained, in contrast to the degenerate-type eutectic structure formed in the Zn-1.5 percent Cu-0.12 percent Ti alloy (fig. 18C).

A further comparison can be noted. The eutectic structures for the two binary alloys containing 0.12 and 0.36 percent titanium (figs. 16B and 16D, respectively), were anomalous after cooling very slowly; however, the eutectic structures were both essentially normal,for the corresponding alloy compositions cast in the graphite mold (figs. 18A and 18D).

As an aid to interpretation and without attempting to discuss physical causes, it should be pointed out that the structures of alloys containing more than about 0.12 percent titanium (such as figs. 18D through 18F) actually contain “primary crystals” of two phases; idiomorphic crystals of the Zn-rich intermediate phase, and dendritic crystals of the zinc solid solution phase. Such a solidification pattern would not occur with strictly equilibrium conditions.

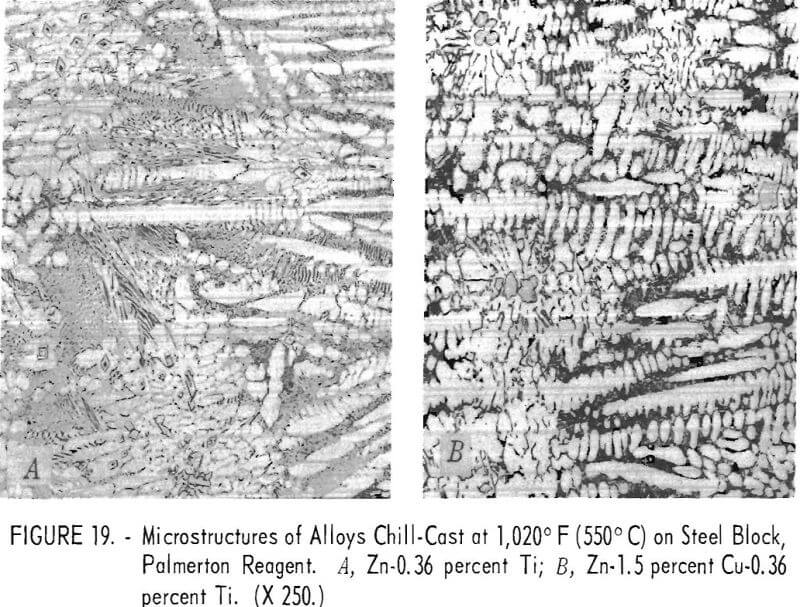

The third series of castings consisted of only two compositions, a Zn- 0.36 percent Ti alloy and a Zn-1.5 percent Cu-0.36 percent Ti alloy. These two alloys were cast at 1,020° F (550° C) in the form of buttons on a cold (room temperature) steel block. The buttons were about ¼-inch thick, and represented castings solidified at the fastest rate of the three series. Photomicrographs were taken on areas of the buttons near the edges that were in contact with the steel block during freezing. The microstructures of these two alloys, shown at x 250 in figure 19, are fairly similar to the microstructures of the center zone of the semicontinuous-cast ingots of the alloys with most nearly the same compositions (figs. 11B and 13B). This similarity confirms that the center zone of the semicontinuous-cast ingots solidifies at a quite rapid rate.

Rolling of Slabs from Semicontinuous-Cast Ingots

The foregoing demonstrates that structural variations occur within given ingots of semicontinuous-cast zinc alloys. Such ingot structure would be expected to form in ingots produced in commercial practice on continuous

casting stands of various designs. The extent of its formation would depend upon the ingot thickness and the casting parameters controlling heat extraction from the ingot, such as the mold configuration, the pouring temperature, the ingot withdrawal speed, and the influx of cooling water. The question naturally arises as to what effect such ingot structure has on the uniformity of sheet rolled from ingots cast by one or another variation of the process.

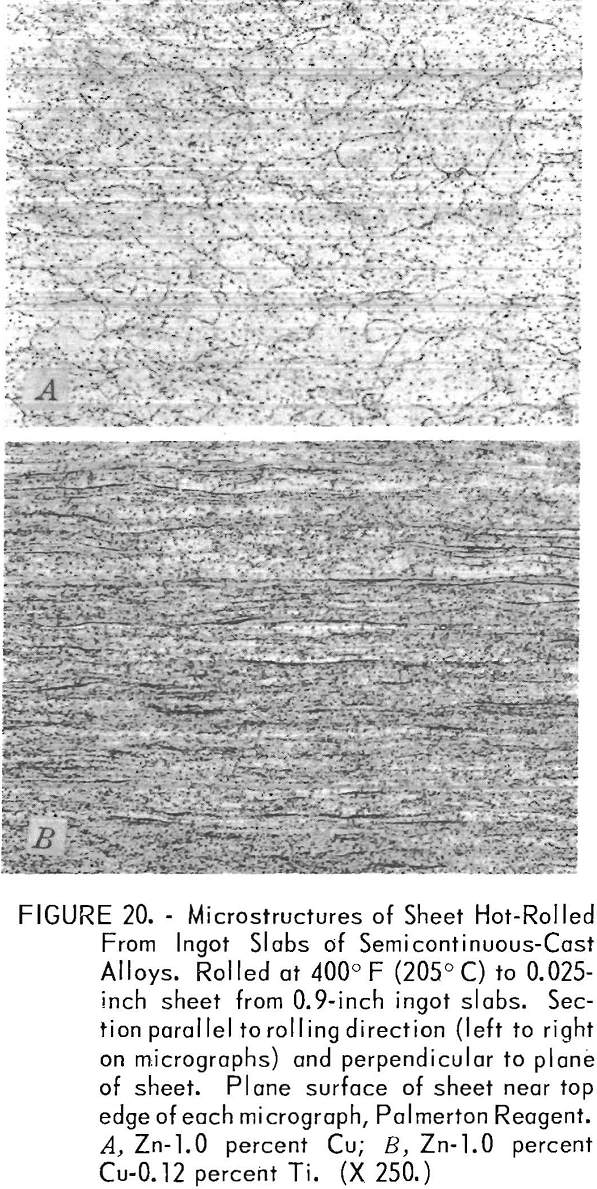

In order to determine the effect, microscopic examination was made of 0.025-inch sheet that had been hot-rolled at 400° F (205° C) from the ingot slabs. The 0.9-inch thick scalped ingot sections had been reduced by about 15 percent per pass while rolling to 0.3-inch thick, and by about 20 percent per pass while rolling to the final 0.025-inch thickness. Total reduction was about 97 percent. The scalped ingot sections were preheated 1-½ hours before rolling, and the slabs were reheated for 20 to 30 minutes between rolling passes. Rolling temperature was taken as the temperature of the soaking furnace. Rolling speed was 156 feet per minute.

Specimens of the rolled 0.025-inch sheet were mounted for microscopy so that sections parallel to the rolling direction and perpendicular to the plane of the sheet could be examined. The microstructures were found to be uniform from edge to edge. Two examples are shown in figure 20. Some precipitation of the Zn-rich, Zn-Cu epsilon phase occurred during the hot-rolling of the Zn-1.0 percent Cu alloy (fig. 20A). There are what appear to be similar precipitate particles, in the directional structure of the hot-rolled Zn-1.0 per¬cent Cu-0.12 percent Ti alloy (fig. 20B), between the TiZn15 phase particles which are aligned in the direction of rolling.

This work demonstrated that the ingot structure present in semicontinuous-cast ingots does not prevent the hot-rolling of the ingots into sheet material

having a uniform microstructure. A substantial number of specimens for subsequent studies have been fabricated from sheet rolled from semicontinuous-cast ingots of Zn-Cu, Zn-Ti, and Zn-Cu-Ti alloys.