Block caving is an efficient mass-production method for the underground mining of large orebodies. However, the block-caving method requires a substantial investment in developmental works, based on the assumption that the rock will cave.

Efficient block caving is prevented if the rock forms stable arches or breaks into fragments that are too large to pass easily through the finger raises. Under these conditions, the cost of the additional labor, drilling, and blasting required to assist caving may be sufficient to make marginal orebodies uneconomic or alternative mining methods more attractive.

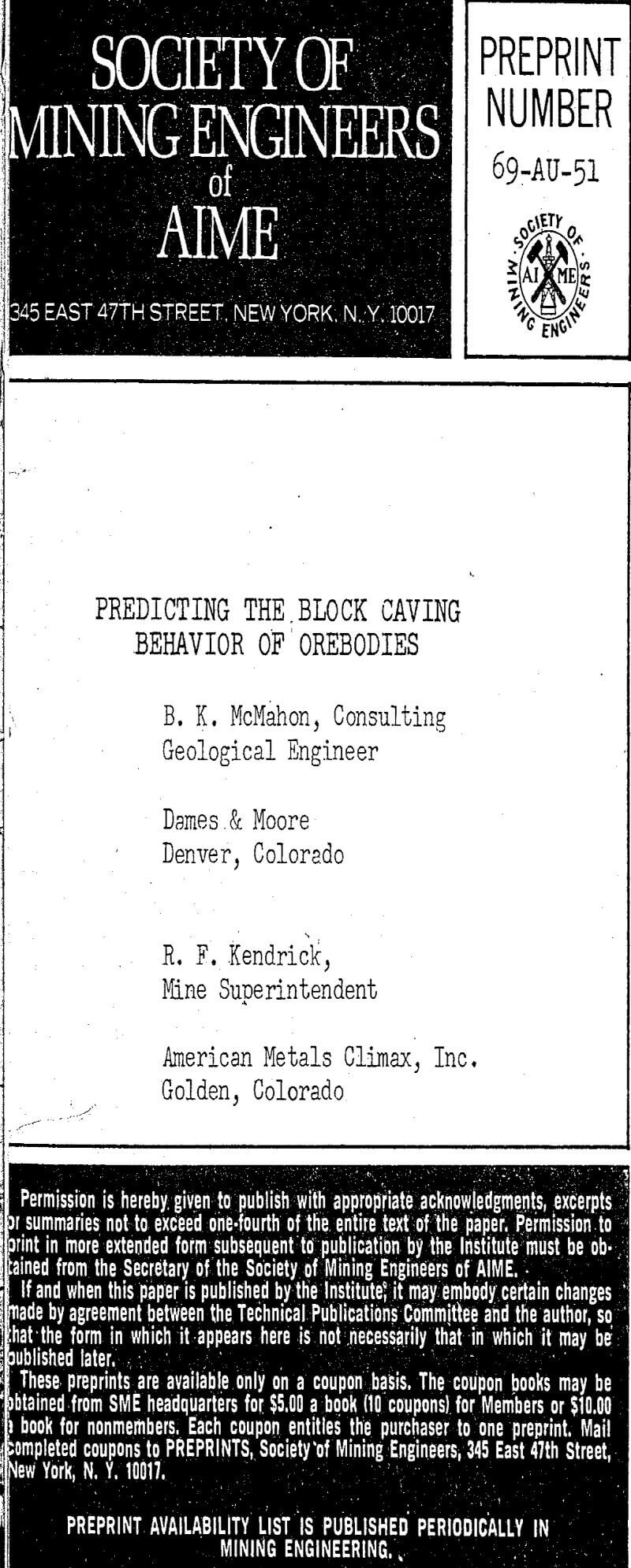

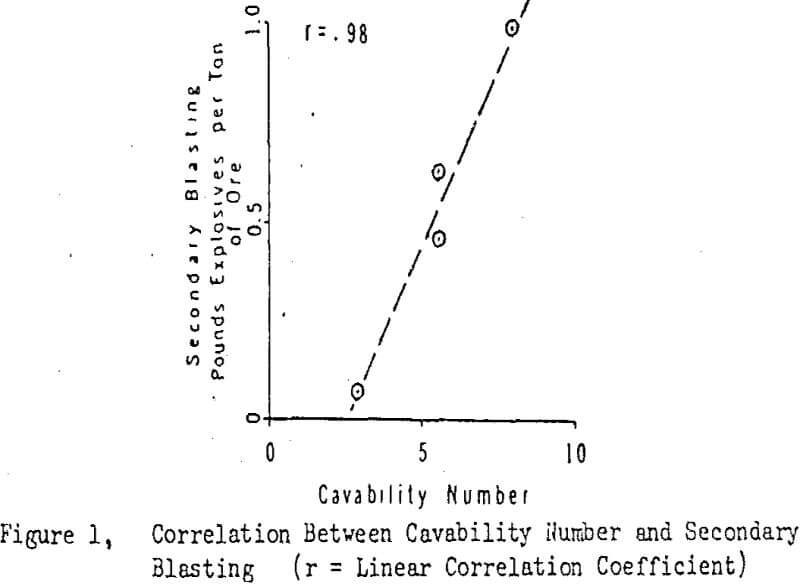

The purely geological aspects of block caving were studied by means of geological indices. These are easily measured and reproducible, numerical properties of the rock mass. Relationships between the various indices and such rock mechanics parameters as compressive or tensile strength and deformation moduli can be established by correlation with test results. The aim of this part of the study was to determine which of the many possible geological indices was most highly correlated with some independent measure of block caving behavior. Clearly, the first step was to set up a measurement of block-caving behavior or “cavability.”

At the beginning of the study, there was considerable feeling that a composite index of cavability was required to reflect such properties as the quantity of secondary blasting, size of the rock blocks, sorting characteristics of the muck, ease of fall through ore passes, and ease of loading onto trains. In order to obtain such a composite index, six experienced mine operators were asked individually to rank the areas that they had worked in the Climax and Urad Mines in order from 1 to 10, where 1 indicated excellent caving characteristics and 10 indicated particularly-poor caving characteristics.

Rock Quality Designation (R.Q.D.)

In order to evaluate the relative benefits of various mining procedures and the possible effects of tectonic and residual stresses on the efficiency of a block cave, it is necessary to have an analytical model capable of taking into account the interaction of the complex geology and topography and the irregular and changing shape of the mine excavation. The finite element method provides such a model.