Table of Contents

Rod mills were developed as a logical substitute for the rolls crusher when larger tonnages had to be handled, on a continuous basis. Today, with even larger tonnages to process, the trend is to install larger equipment, automate the plant and develop the highest availability possible, in order to cut costs. The rod mills, because of design limitations in size and speed, are not able to meet these new requirements.

Practical Considerations

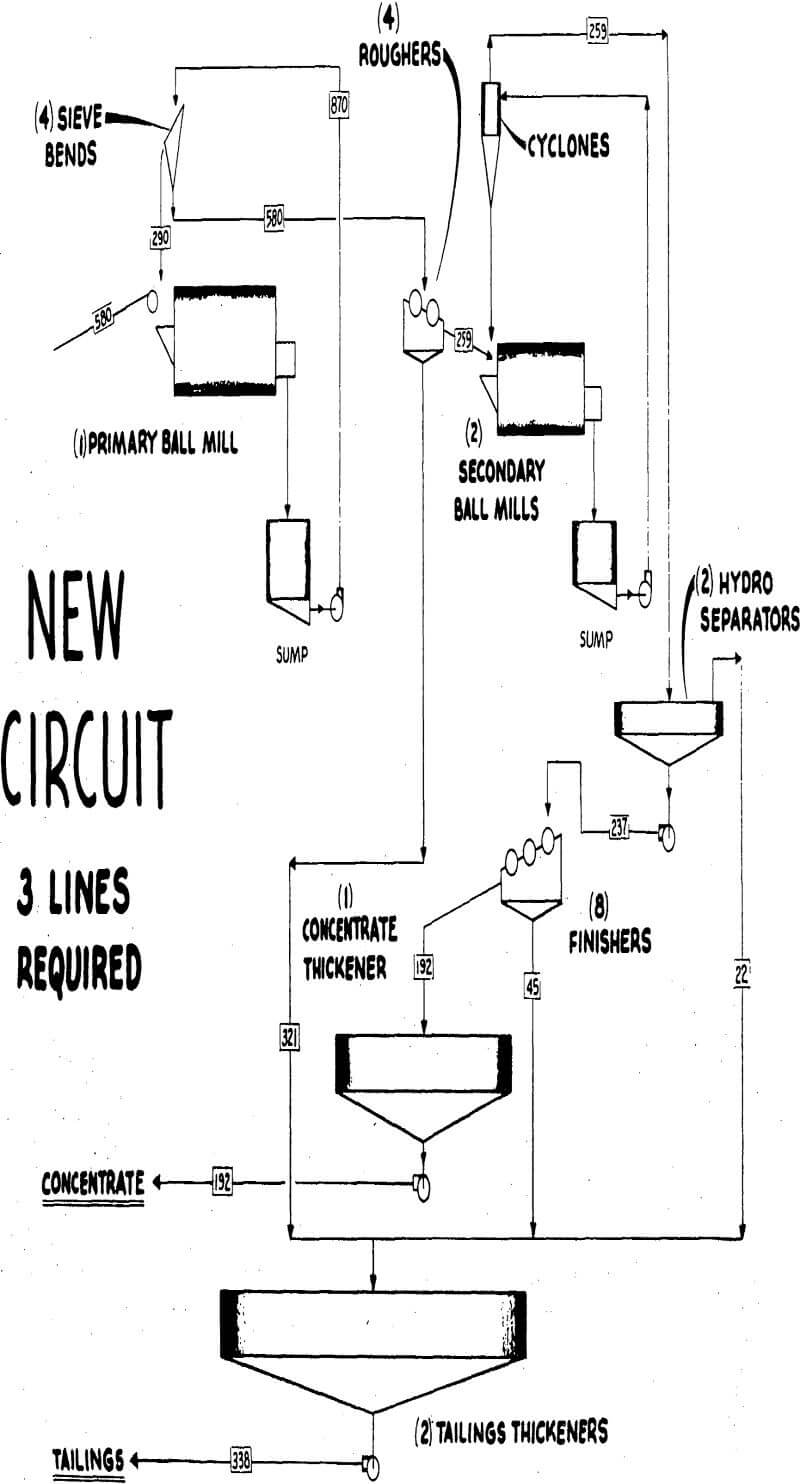

One of the primary reasons for investigating alternate flowsheets is the desire to reduce cost. Two flowsheets have been developed to compare capital and operating costs for a taconite plant with 4.5 million long tons per year concentrate production capacity at an assumed concentration ratio of 3:1.

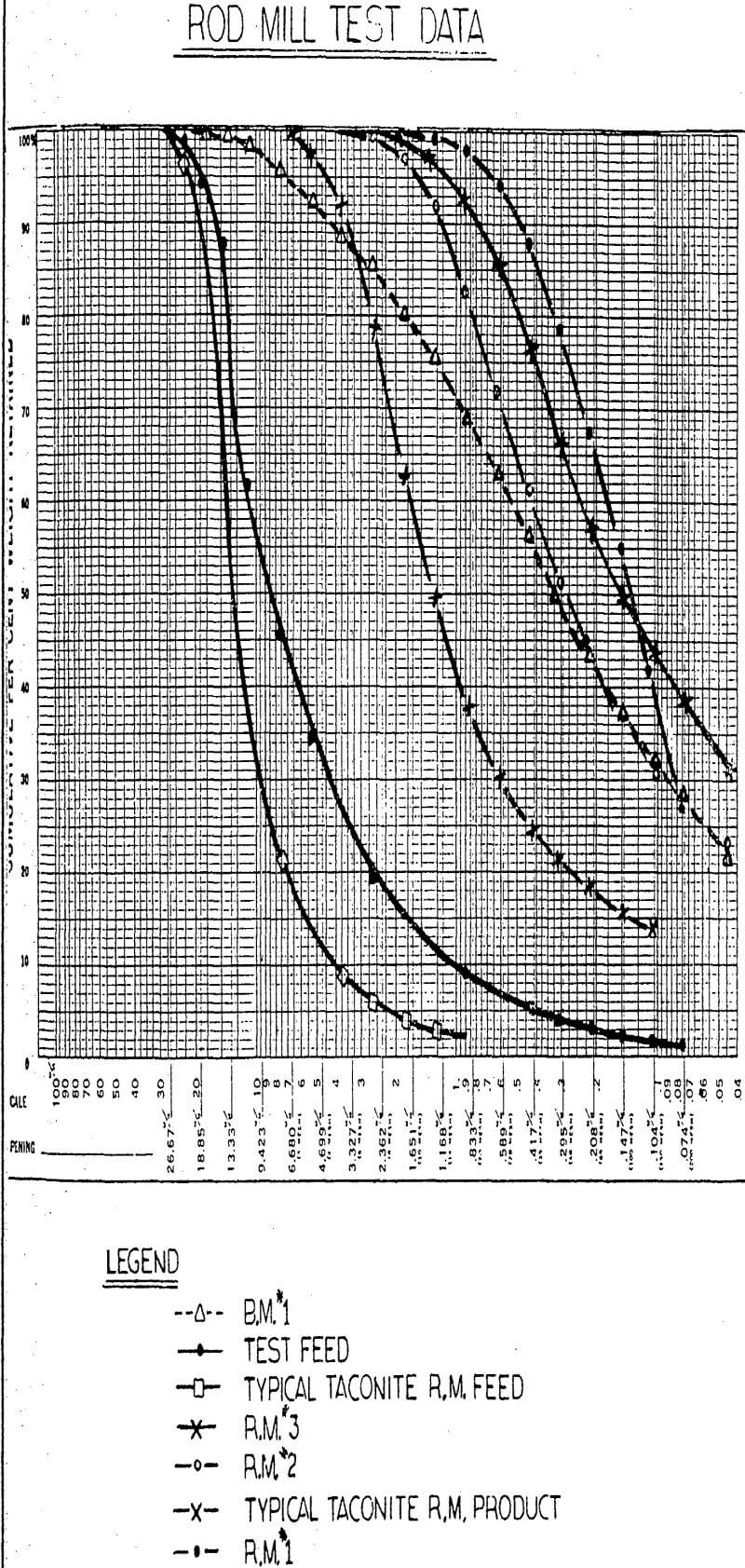

The first flowsheet is a conventional circuit in which -¾” tertiary crusher product is fed to a rod mill drawing 4.6 Kwhr/Ton and producing an 80% -10 mesh product. At this stage 40% of the rod mill product is rejected in cobber magnetic separators as tailings. The cobber concentrate is ground in two ball mills in closed circuit with rougher, magnetic separators and cyclones. The calculated.ball mill power consumption is 13.8 Kwhr/Ton of crude. The cyclone overflow is deslimed, and upgraded in finisher magnetic separators.

Diameter to Length Ratio in Mills Rod mill L/D ratio is about 1.4:1. Pilot scale tests suggest that this should be revised to about 2:1 in the case of primary ball mills. This will off-set the effect of the random action of the balls and produce a smaller circulating-load.

Costs

The estimated savings is 10.5 cents per ton of crude which is a conservative figure. This, comparison takes into account only the most important aspects of the concentrator costs as a first approximation. It does not include pumping costs, maintenance costs and operating labor costs but all of these, would favor the proposed new circuit thus making the cost differential even more marked. Relative mill availability has not been considered in this cost evaluation, but it can also represent a considerable saving. The ball mill availability ranges between 94-96% whereas that of the rod mill ranges between 92-94% particularly because of stoppages for rod charging.

Capital costs were, developed for the two plants based on a location on the Iron Range. Support facilities, feed preparation or product handling were assumed to be essentially the same for both plants. These include ore crushing and stockpiling, maintenance shops, offices, water supply, tailings, disposal, etc., and were not made a part of this comparison. The saving of six million dollars, or 27% of scope considered, was to be expected.

Theoretical Considerations

In a “tumbling” type of mill, the size reduction can result from direct crushing, from shearing or abrasion between the particles in the feed, between the particles in the feed and the mill media or between the particles and the mill lining and thus is a complicated process. The precise mode of transfer of energy to the crushing surfaces cannot be simply presented.

For hard ores the influence of ball size is less pronounced and larger balls have little effect on grinding efficiency. Also from a simple graphical analysis of the “zone of operation” idea it follows that the radius of the zone varies as the square root of the particle diameter. Other things being equal, there is increased tendency for preferential grinding of the larger particles. As would be expected, the grinding of coarse feed with small balls did not result in effective grinding of the coarse particles in the feed but only produced considerable amounts of fines.