Table of Contents

Mercury is customarily recovered from its ores by roasting sulfide minerals and condensing the vapors to obtain the metal. The process is efficient from the standpoint of mercury removal from the calcine; however, vapor and particulate losses in the condensing system, as well as the loss owing to recombination of the mercury with sulfur, can be substantial. These losses are usually aggravated when low-grade or wet ores are processed because vapor and particulate losses are directly proportional to the flue-gas volume.

A hydrometallurgical approach to mercury recovery from cinnabar offers several benefits: (1) Environmental pollution in the form of SO2 and mercury vapor in the flue gas is eliminated; (2) the hazard of salivation to plant employees by accidental exposure to mercury vapors is minimized; (3) mercury recovery from low-grade ores is often more efficient; and (4) the method is simple and suitable for various sizes of operation.

Hydrometallurgical treatment of mercury ores has been considered by several investigators. The dissolution of cinnabar by basic sodium sulfide and hypochlorite solutions is well known, and attempts have been made in the past to exploit procedures based on this chemistry to develop commercially acceptable processes for mercury recovery. More recently, G. A. Parks was issued a patent for a process employing the leaching of cinnabar with sodium hypochlorite and carbon adsorption for recovering the mercury from solution.

An electrooxidation process, originally developed by the Federal Bureau of Mines for pretreatment of carbonaceous gold ores, was observed to be effective in dissolving mercury that was also present in the ore in small amounts. Subsequent investigations have shown electrooxidation procedures to be effective in extracting mercury from a variety of ores and concentrates. This paper is concerned with amenability tests conducted on eight different mercury ores from Utah and Nevada.

Theory

The oxidizing conditions required to dissolve mercury are generated by electrolysis of finely ground ore pulped in brine. The chloride ion is converted to chlorine at the anode, as shown in equation 1,

2Cl- → Cl2 + 2e-………………………………………………………………..(1)

At the cathode, water is hydrolyzed to produce hydroxyl ion and hydrogen according to equation 2,

2H2O + 2e- → H2 + 2OH-……………………………………………………(2)

Equation 3 shows the reaction between chlorine and the hydroxyl ion, which produces hypochlorite and chloride ions and water,

Cl2 + 2OH- → OCl- + H2O + Cl-…………………………………………….(3)

The dissolution of mercury in cinnabar may be visualized as a two-step process involving oxidation of the sulfide followed by reaction of the sulfate with chloride ion, as shown in equations 4 and 5. The mercury is carried in solution as a stable tetrachloride complex.

HgS + 4OCl- → HgSO4 + 4Cl-…………………………………………………(4)

HgSO4 + excess Cl- → HgCl4²- + SO4=…………………………………..(5)

Also, some direct oxidation of the cinnabar apparently occurs at the anode to produce mercuric sulfate. This reaction is shown in equation 6,

HgS + 4O= → HgSO4 + 8e-……………………………………………..(6)

Process Description

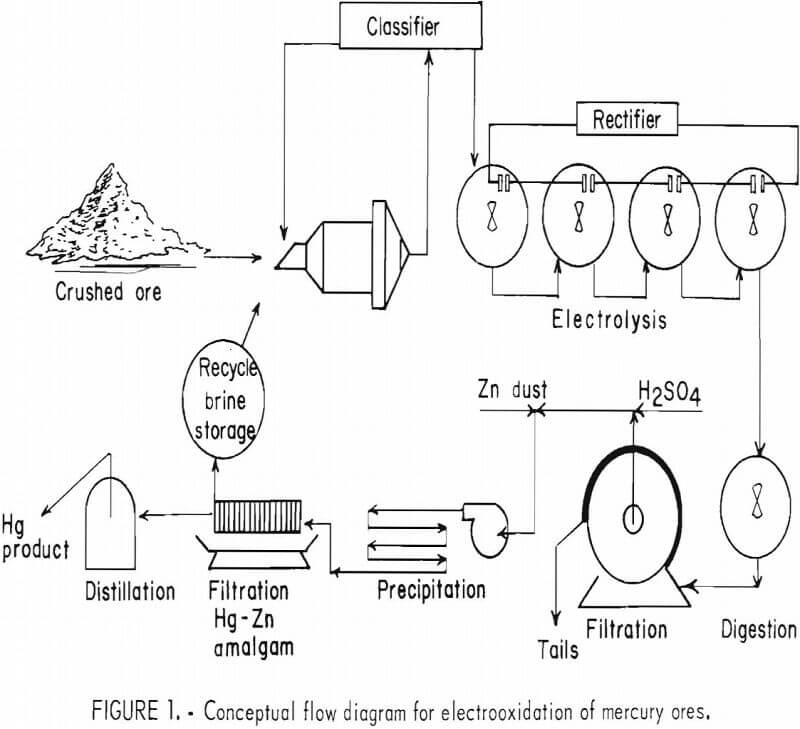

Figure 1 shows a conceptual flow diagram developed as a result of laboratory experiments conducted on several different mercury ores. The procedure consists of crushing and grinding the ore, forming a pulp with brine, and electrolyzing the pulp to oxidize minerals to form brine-soluble compounds. Conventional liquid-solid separation techniques are employed to obtain a reasonably clear pregnant solution from which the mercury is precipitated as an amalgam by an active metal such as zinc.

Amenability experiments were conducted in the installation shown in figure 2. Equipment consisted of an 18-inch by 3-foot rodmill, four rubber-lined 55-gallon electrolysis tanks fitted with marine-type agitators, a 55-gallon agitated digestion vessel, five 3- by 3-foot thickeners, a 1- by 3-foot rotary vacuum filter, and a precipitation unit. Each electrolysis tank was fitted with an electrode unit consisting of four anodes sandwiched between five cathodes that were connected in parallel. Direct current was supplied by a silicon rectifier. Mill capacity varied between 1.4 and 1.8 tons per 24-hour day, depending on the ore being processed.

The ore was wet ground to 90 to 96 percent minus 65 mesh in a solution of 4 to 10 percent sodium chloride. This solution served as an effective electrolyte as well as a chemical reactant. The mercuric sulfate product and the hydrolyzed product, basic mercuric sulfate, are both relatively insoluble in water. However, in brine the soluble tetrachloro mercury complex is formed.

The electrodes were immersed into the pulp, and the electrolysis was started. Agitation of the pulp during electrolysis was necessary to insure passage of the pulp between the electrodes to effectively disperse the oxidizing species produced at the anode throughout the ore pulp. The hypochlorite ion reacted rapidly with the cinnabar in the agitated cell, thus maintaining hypochlorite concentration at a low level so that undesirable oxidation reactions were minimized.

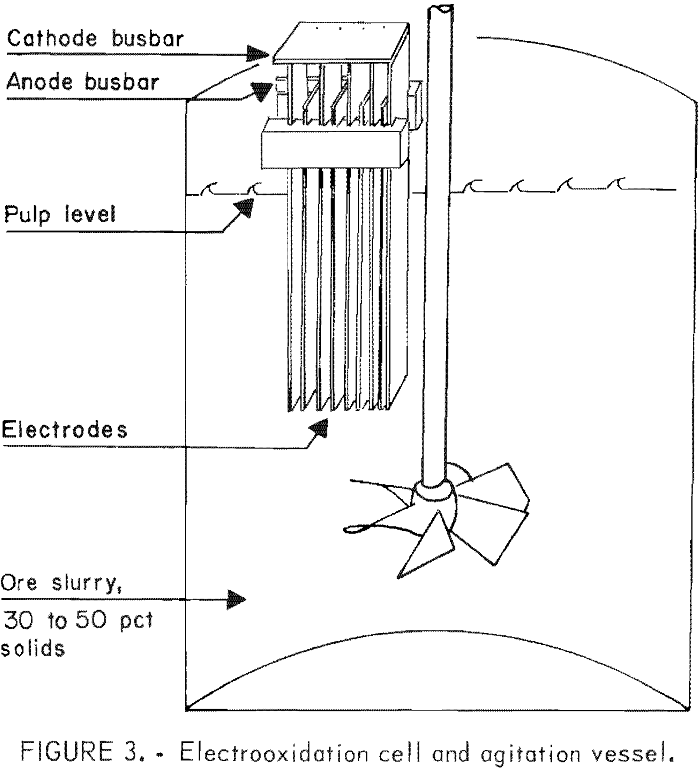

Since the ore particles suspended in the brine tend to inhibit conduction of current through the cell, it is necessary to space the anode and cathode as close as possible, but the spacing must be sufficient to allow free passage of the material between the electrodes. It was found that an electrode spacing of ¼ to ½ inch for electrodes 3 to 4 inches in width gave the most satisfactory results. A conceptual electrode assemblage is shown in figure 3. In the testing operations, the cell consisted of a rubber-lined 55-gallon drum, with agitation provided by a 10-inch-diameter impeller. This particular cell design consisted of four graphite anodes positioned between five graphite

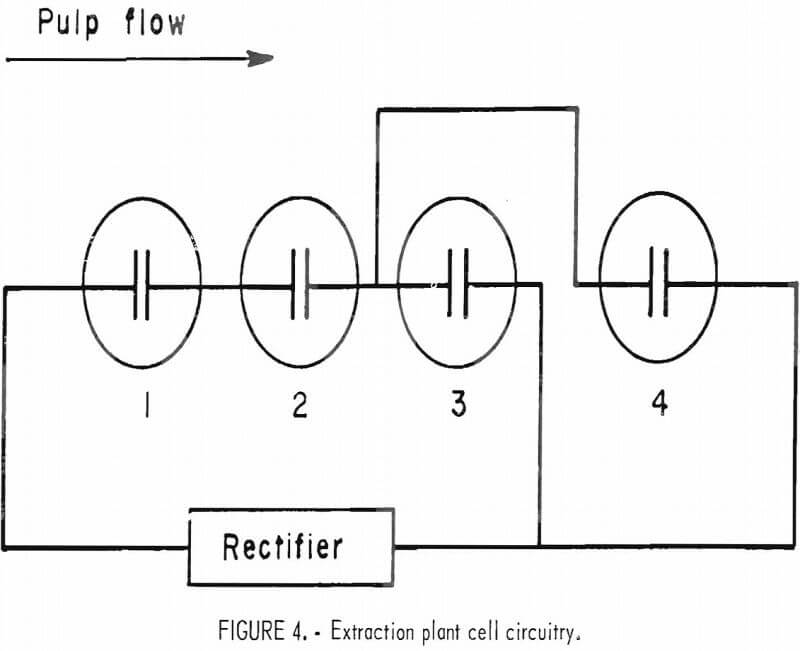

cathodes. All electrodes were made from ¾-inch graphite sheet: and were 3 to 4 inches wide. Electrodes extended 20 inches below the surface of the brine pulp. Continuous flow of the pulp through four electrolytic cells placed in series was effective for treating the ores. A fifth drum fitted with an agitator was placed at the end of the circuit to allow residual hypochlorite to react with the pulp before entering the liquid – solid separation sequence. The current requirement was determined by the rate of flow of the particular ore being treated. Retention time in the entire 4-cell electrolytic system was 4 to 6 hours. Energy consumed in electrolysis depended on the ore being treated and ranged from 17 to 64 kilowatt-hours per ton of ore. The current density ranged from 0.3 to 0.7 ampere per square inch of electrode surface.

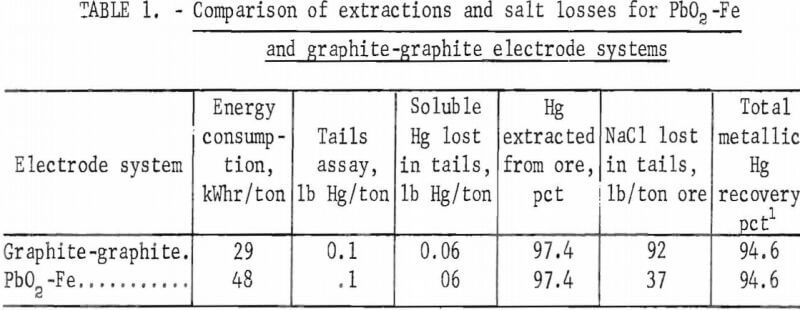

Two types of electrode systems were evaluated, one utilizing an iron cathode and a lead-dioxide-coated titanium anode and another using an all-graphite system. A salt concentration of about 8 to 10 percent was required with the graphite-graphite electrode system to prevent oxidation of the anode, whereas a 3- to 4-percent salt solution can be used with an iron-lead dioxide electrode system without degradation of the anode. Energy consumption in the 4-percent salt solution was about 20 percent higher than that required with the 10-percent salt solution.

The pH of the electrolyte was usually allowed to follow the natural pH resulting from contact of solution with the ore. This usually reached steady state in the pH 6 to 7 range and is consistent with efficient production of hypochlorite in the electrolysis of salt solution.

The rate of reaction in oxidizing cinnabar was found to increase with temperature; however, the stability of hypochlorite decreases with increasing temperature so that the optimum operating temperature is in the range of 25° to 40° C.

The technology of liquid-solid separation for recovery of a pregnant solution closely follows conventional practice used in countercurrent decantation (CCD) slimes circuits. Solution balance was achieved in the system, maintaining recycle of all salt solutions except those discharged in the tails. Ball mill discharge was held at a nominal 60 percent solids, the electrolytic cells were maintained at 35 percent solids by dilution with recycle brine, and the CCD circuit was operated at 20 percent solids by washing with recycle solution. Tails from the CCD circuit were discharged from the system at 60 percent solids and mixed with fresh makeup water in a simulated tailings pond sequence to recover as much salt as possible. Liquid-solid separation by filtration instead of by countercurrent decantation employed a two-step washing, first with recycle brine to wash dissolved mercury from the interstices of the gangue particles and then with fresh makeup water to displace salt water from the filter cake. The more efficient materials handling possible in actual plant operation could be expected to achieve somewhat lower salt losses in both filtration and tailings pond operation. If the ore contains considerable quantities of clay, countercurrent decantation or washing is usually required to achieve low soluble mercury values in the mill tails. Liquid-solid separation by filtration is generally favored whenever permitted by the character of the ore. Whereas soluble mercury losses to the tails are approximately equal to those obtained with countercurrent decantation, the sodium chloride losses encountered in filtration are only one-half of the loss in a countercurrent decantation circuit. This occurs because the concentration of solids in filter cakes is greater than those in thickener underflow products, and in addition, the salt can be effectively recovered from a filter cake by a displacement wash with fresh water. Since salt losses in the tails can represent an important economic factor, careful tailings pond operation is necessary.

Precipitation of mercury from pregnant solutions by an active metal is readily accomplished without the degassing and clarification required by the classical Merrill Crowe process for gold precipitation from cyanide solution. Precipitation is rapid, effective, and essentially complete at a pH of 7.0 by contacting the pregnant solution for 2 minutes with 200-mesh metallic zinc dust in the amount of 1.5 pounds of zinc per pound of mercury, or with 200- mesh metallic iron powder in the amount of 2.0 pounds of iron per pound of mercury. During precipitation, the iron salts are immediately hydrolyzed to an iron hydroxide that coprecipitates with mercury. Many cinnabar ores contain small amounts of gold and silver-these values are dissolved along with the mercury during electrolysis and are coprecipitated with mercury on the zinc.

The pH at which the mercury may be effectively precipitated from solution is dependent on the residual sodium hypochlorite concentration. To precipitate at a pH of 7, the sodium hypochlorite level must be below 0.05 percent. This low sodium hypochlorite concentration can be achieved by carefully controlling the treatment time and by providing sufficient digestion time to allow residual sodium hypochlorite to react with the gangue or disporportion- ate to a nonoxidizing species. If the sodium hypochlorite level is between 0.05 and 0.20 percent, the pH must be lowered to 2.5 to 3.0 with sulfuric acid before effective precipitation is obtained. When a low pH is used in the precipitation sequence, the pH of the resulting barren solution must be raised to 7 with lime before it can be recycled.

The precipitation of mercury from solution with zinc dust results in a product that consists of a zinc amalgam with a nominal composition of 40 percent mercury and 60 percent zinc, including minor amounts of lead, silver, gold, copper, etc. Essentially complete mercury recovery from the amalgam is readily accomplished by distillation at 600° C and condensation of the vapors. The zinc calcine may be washed with ammonium hydroxide to remove that portion of zinc oxidized during distillation of the mercury and then recycled to the precipitation unit. Correspondingly, the precipitation of mercury from solution with iron powder results in a mixture of iron, iron hydroxide, and mercury, with a mercury content of 30 to 40 percent. This precipitate also contains trace amounts of lead, silver, gold; copper, etc. Mercury is recovered from the precipitate by distillation at 600° C.

Results and Discussion

Eight ores were treated in this simulated plant operation. Results obtained from treating two of these ores are presented in detail, and the remaining six are summarized. Ores selected for detailed presentation were chosen to show the differences in extraction characteristics of ores as well as some of the problems encountered in materials handling of ore pulps that settle readily versus those that do not. The first ore responded to electrooxidation readily but settled relatively slowly so that use of a CCD washing circuit was necessary, and salt losses to the tails were relatively high. The ore was made up of a variety of silica minerals, including clear grains of crystalline quartz, semiopaque grains of opaline silica, and silicified rock fragments of unclear origin, many of which showed what appeared to be “casts” from weathered feldspar. Cinnabar mineralization was concentrated in these “cast”-type fragments. The ore was ground to 90 percent minus 65 mesh with a 10-percent recycle brine solution. Analysis of screen fractions indicated that the mercury content in the minus 65- to plus 200-mesh fraction was fairly constant at 2.1 to 2.5 pounds of mercury per ton while the slimes contained 6.0 pounds mercury per ton. Mercury content of the heads averaged 4.2 pounds per ton. The pulp density at the rodmill was maintained at 58 percent and was then diluted to 37 percent solids for agitation during electrooxidatlon.

Electrolysis was started with graphite electrodes that consisted of four anodes 2.5 inches by ¾ inch thick and 24 inches in length, interspaced between five cathodes of the same size. Anode-cathode spacing was ½ inch, and they were immersed into the pulp to a depth of 20 inches. Figure 4 shows the circuitry used in connecting the electrode systems to the rectifier. Cell number 3 was connected in parallel to cell number 4, and these cells were connected in series with cells 1 and 2. Under these conditions, and using the 10-percent salt solution to pulp the ore, cell voltages ranged from 4 to 4.4 volts, and the rectifier supplied 120 amperes at 12.6 volts. The current density was 0.50 ampere per square inch.

Ore was fed through the system at a base line rate of 130 pounds per hour, corresponding to a retention time of 5 hours in the 4-cell electrolysis system. A total of 1 ton of ore was processed for each experiment. Liquid-solid separation for each was performed in the conventional countercurrent decantation

system described earlier. Mercury precipitation from pregnant solution and subsequent distillation were conducted according to the aforementioned procedure.

Mercury extractions of 97.4 percent were obtained with an energy consumption of 29.0 kilowatt-hours per ton. Sodium chloride loss in the tails was 92 pounds per ton. This same ore was used for experiments in which the salt concentration in the pulp was maintained at 5 percent, and lead dioxide-coated titanium anodes and iron cathodes were used. The configuration and dimensions of the cell assemblage were the same as used in the graphite electrode system in previous experiments. Other experimental conditions were identical to those employed with graphite electrodes. To obtain a 97.6-percent extraction, 48 killowatt-hours of energy per ton of ore was required. Table 1 shows a comparison of the data obtained with the two electrode systems. This is an increase of 19 kilowatt-hours per ton of ore, which was caused by the loss in conductance when going from 10 to 5 weight-percent sodium chloride solution. However, the advantage in using lead dioxide anodes lies in the salt consumption. Whereas salt lost to the tails with the graphite electrodes was 92 pounds per ton of ore, only 37 pounds salt per ton of ore was lost to the tails when using lead-dioxide anodes. If the mill were operated in an area where power was inexpensive but salt costs were high, the use of lead dioxide anodes with iron cathodes may be favored. Conversely, if salt was inexpensive and cost of power high, the graphite electrode system would be favored.

The second ore selected for detailed presentation not only responded favorably to electrooxidation, but it settled rapidly so that either filtration or countercurrent decantation could be used for liquid-solid separation. The ore consisted primarily of quartz, calcite, and dolomite. The dolomite and calcite were intermixed with the quartz in amounts ranging from 95 percent quartz to less than 50 percent. Many small grains of oxidized iron minerals were noted, but very little clay was present. The cinnabar occurred as isolated grains throughout the host rock. Some very fine veinlets of cinnabar were found to be distributed throughout the silicified calcite and dolomite. The ore had a specific gravity of 2.8. This ore was ground in a 10-percent salt solution to 90 percent minus 65 mesh. Analysis of the screen fractions showed that the mercury content of the various fractions ranged from 0.8 pound mercury per ton in the plus 65-mesh fraction to 2.5 pounds mercury per ton in the minus 200-mesh fraction. Mercury content of the heads averaged 2.5 pounds per ton. The pulp density at the rodmill was maintained at 65 percent solids and was diluted to 44 percent solids for agitation during electrolysis.

Electrolysis was conducted with graphite electrodes and electrical circuitry identical to that used in the previous experiment. Cell voltages, with the 10-percent salt solution used to pulp the ore, ranged from 2.9 to 4.4 volts, and the entire circuit drew 120 amperes at 12.6 volts.

Ore feed rate through the system was 130 pounds per hour, corresponding to a retention time of 5 hours in the entire 4-cell electrolysis system. A total of 1 ton of ore was processed for each experiment. Liquid-solid separation was performed both in the conventional countercurrent decantation system described earlier and by filtration. Mercury precipitation on zinc and distillation of mercury from the resulting amalgam was accomplished according to the procedure previously described.

Mercury extraction was 96 percent with an energy consumption of 23 kilowatt-hours per ton of ore. Sodium chloride loss in the tailings was 47 pounds per ton of ore.

This ore produced little slime and settled favorably; consequently, another experiment was conducted using a 3-foot-diameter by 1-foot wide rotary drum filter for liquid-solids separation. The pulp was thickened from the 44-percent solids maintained during electrolysis to 60 to 66 percent in one thickener before filtration. Other experimental conditions were identical to those used in the previous experiment. A thick porous cake was obtained, and washing of the cake with fresh makeup water was effective. Sodium chloride lost in the tailings was reduced from 47 pounds per ton of ore for the CCD circuit to 22 pounds per ton of ore for the circuit utilizing a filter. The overall recovery of mercury was identical for the CCD and filter circuit.

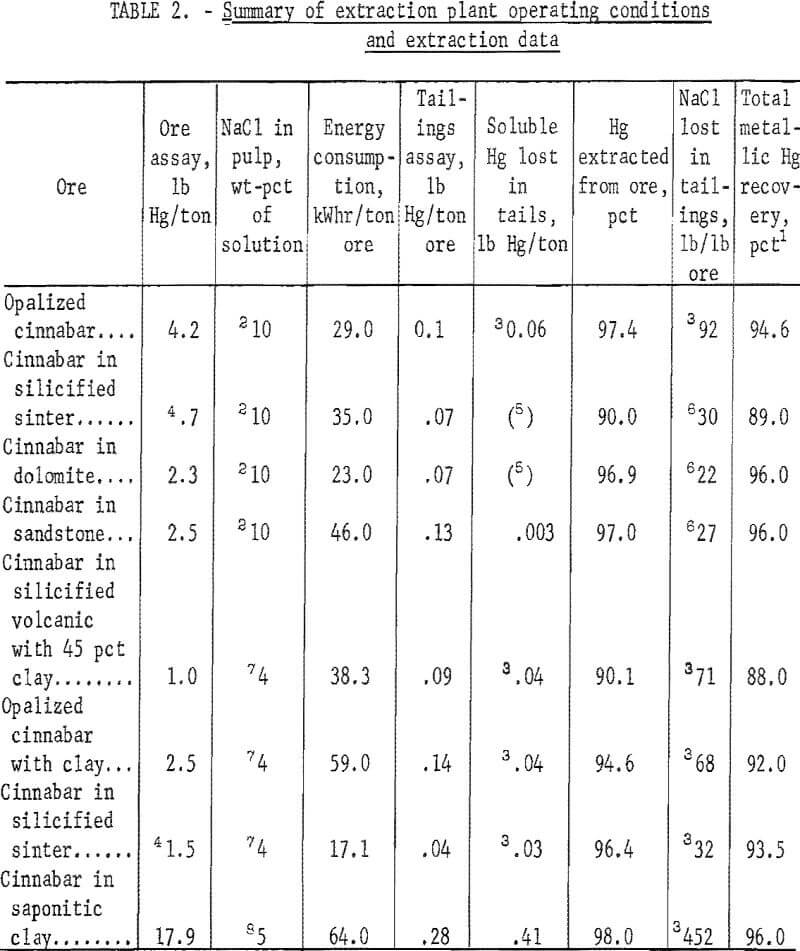

Testing plant operating conditions and extraction data for experiments on the remaining six ores are summarized in table 2. Data from the two experiments presented in detail are repeated for comparison. Data for the first four experiments were obtained with a graphite-graphite electrode system, using 10 percent sodium chloride in the pulp. The next three experiments were conducted in a nominal 4-percent salt solution using the lead dioxide anodes with iron cathodes. The last experiment was conducted with flow-through cells made of six graphite plates 5½ inches wide by ½ inch thick, spaced ½ inch apart and enclosed in a 6-inch-diameter PVC pipe The pulp was circulated up through the cell by means of air introduced at the bottom of the electrode assembly. The cells were operated in the bipolar mode. The electrical connections were made only at the two end electrodes of each cell with the four inter-electrodes being unattached to the electrical system. The inter-electrodes function as both anode and cathode with a full voltage drop averaging 2.8 volts, occurring between each plate of the cell. The cells were connected in series in the four agitator drums. No additional agitation was needed.

Extraction was generally in the 95-to-97-percent range except with the two ores that have head analyses in the 1-pound-per-ton range. Extraction from both of these ores was close to 90 percent. Mercury losses of 2 to 3 percent in the liquids-solids separation step and in the precipitation and distillation steps are reflected in the total metallic mercury recovery values. Recovery from the two ores with heads in the 1-pound-per-ton range was 88 to 89 percent, whereas recovery from ores above 1 pound per ton fell in the 92-to-95-percent range. It is worthy of note that the tail assays are fairly independent of the head assays, and the amount of mercury remaining after extraction, for the two ores with low head assays, compares favorably with the other ores. The data indicate that mercury extraction obtained with the bipolar cell system closely parallels that obtained with the cells employing parallel circuitry.

Loss of mercury as dissolved salts in the solution that was entrained in the interstices of the gangue or tails (soluble Hg loss) generally ranged from 0.03 to 0.06 pound mercury per ton tails except in the last experiment and in experiments utilizing filtration. Soluble loss incurred during filtration was not determined separately but appears with the tail analysis.

Salt loss to the tails is a function of the settling characteristics of the ore and the type of liquid-solid separation used. The two ores that proved to be amenable to filtration resulted in salt losses of 22 to 30 pounds per ton ore, whereas those ores that required countercurrent decantation treatment generally resulted in salt losses between 32 and 92 pounds per ton. The ore treated in the last experiment contained a considerable amount of saponitic clay, and liquid-solids separation was almost impossible. Dissolved mercury was washed out of the solids fairly successfully with salt solution but salt losses ranged as high as 450 pounds per ton of ore. Economical treatment of this ore would require operation of an evaporation pond to recover salt from the mill tailings

The same brine-electrolyte was utilized and recycled in experiments on all of the ores. No buildup of deleterious components in the brine was noted after 4 months of recycling.

The data show that energy consumption per ton of ore is not a function of mercury content of the ore. Stoichiometric requirement of NaOCL for oxidizing cinnabar, according to equation 7, amounts to 1.28 pounds NaOCl per pound HgS,

HgS + 4NaOCl → Na2HgCl4 + Na2SO4……………………………………………….(7)

Since approximately 1.5 to 2 kilowatt-hours of energy are required to produce 1 pound of NaOCl in a 10-percent salt solution, the theoretical energy required per pound of cinnabar amounts to 2.56 kilowatt-hours. Energy consumption data obtained in this work indicate that a 1.3- to 17-fold excess of the theoretical oxidizing capability is required, depending on the character of the particular ore being treated. The ore treated in the last experiment was shown to be very unusual in that a substantial portion of the mercury mineral was not cinnabar. Mineralogical studies indicated that the mercury mineral contained in the clay matrix consists of a new mineral with the composition,

Hg3Cl2S2………………………………………………………(8)

This mineral was shown to be quite susceptible to electrooxidation, and power consumption required to solubilize 98 percent of the contained mercury was only 30 percent in excess of theoretical.

Conclusions

Mercury in cinnabar ores was shown to be amenable to recovery, hydrometallurgically, by an electrooxidation procedure involving electrolysis of the ore pulped with brine. Recovery of 88 to 96 percent of the mercury as metal from cinnabar ores was shown to be feasible with the consumption of 17 to 60 kilowatt-hours of energy per ton ore and 22 to 92 pounds salt per ton of ore. Precipitation of the mercury from solution was accomplished using 1.5 pounds of zinc or 2.0 pounds of iron per pound of contained mercury. Mercury recovery from the precipitate was readily accomplished by distillation at 500° to 600° C.