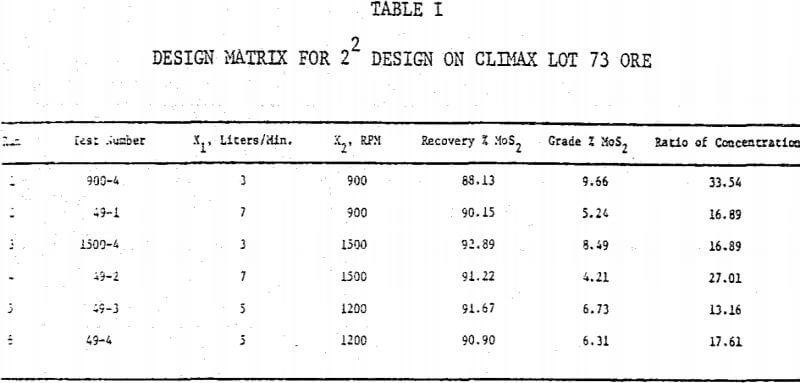

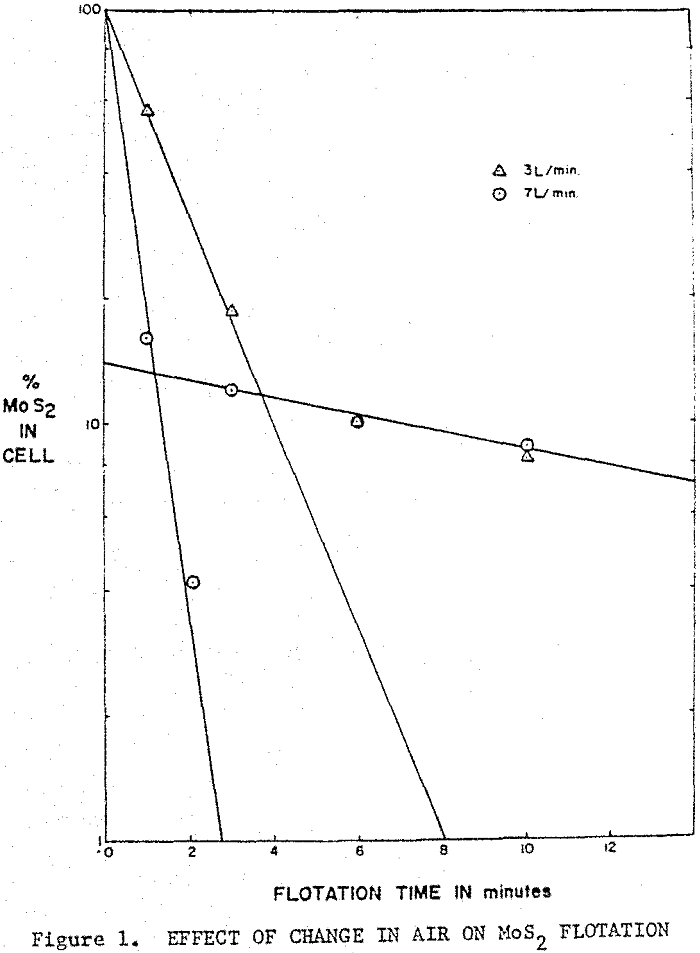

The number of variables which can effect flotation of molybdenite is very large. The analysis of flotation results indicate that molybdenite can be characterized into fast-floating and slow-floating components. The rates of fast-floating components, which do not create a problem in flotation, could be varied by changing agitation of airflow rates.

Experimental

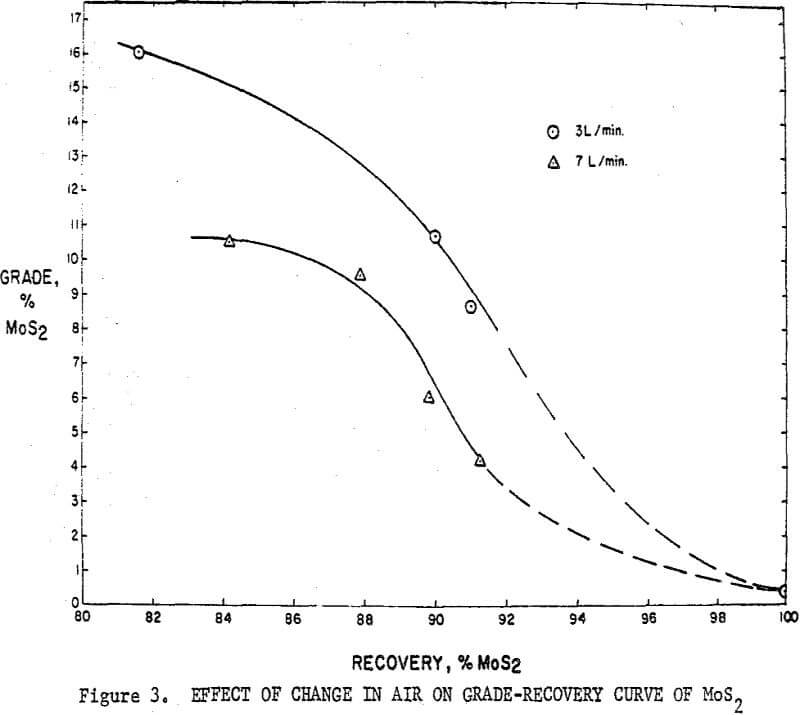

For the laboratory flotation response experiments, a composite sample of Climax ore designated Lot 73 (representing the ore being treated at the Climax mill during the year 1973) was used. The ore was ground at 60% solids in a ball mill with “standard” reagent additions to 35% +100 mesh for all the test-work. The reagent additions were 0.03 lb/ton Nokes reagent, 0,005 lb/ton sodium cyanide, 0.50 lb/ton vapor oil, 0,05 lb/ton pine oil and 0.04 lb/ton Syntex.

The linear models (in the coded form) derived from the experimental data are:

YR3 = 76 + 10.48X1 + 9.62X2 – 8.28X1X2

YG3 = 13.68 – 3.42X1 – 0.88X2 + 0.23X1X2

YR6 = 86.75 + 2.45X1 + 3.75X2 – 3.15X1X2

YG6 = 8.73 – 2„28X1 – 0.48X2 + 0.03X1X2

YR10 = 90.6 + 0.1X1 + 1.45X2 – 0.95X1X2

YG10 = 6.93 – 2.18X1 – 0.58X2 + 0.03X1X2

where: X1 = airflow rate

X2 = RPM in float cell

YR3, YR6 and YR10 are recoveries of MoS2 for 3, 6 and 10 minute flotation times respectively and

YG3, YG6, and YG10 are grades of MoS2 for 3, 6 and 10 minutes flotation time respectively.

Discussion

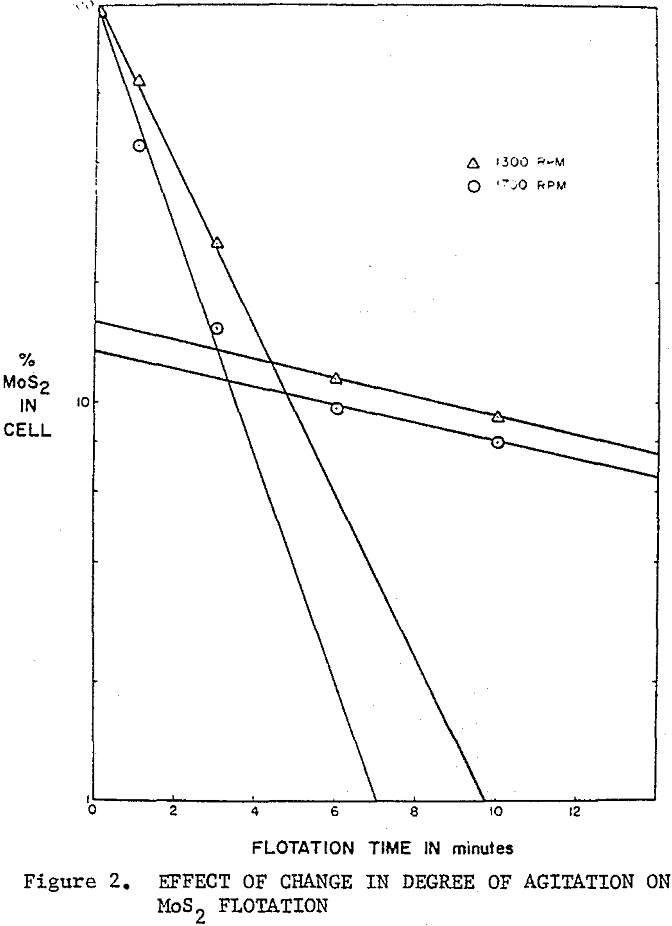

The positive signs for X1 and X2 in the recovery model indicate that higher degree of aeration and agitation improve the recovery of MoS2. However, higher aeration and agitation have a negative effect on the grade of MoS2. There appears to be a negative effect of the interaction of agitation and aeration on the recovery of MoS2 but negligible effect on the grade of MoS2. The reasons for this interaction being negative are not known at this time.

The sensitivity of the recovery and grade of MoS2 to changes in aeration and agitation rates was evaluated. For a change in airflow rate from 3L/min to 7L/min, an incremental recovery of 0.03% MoS2 is obtained for a decrease in grade of 1.09% MoS2. On the other hand, a change in degree of agitation of 100 RPM improves recovery by 0.81% for a drop in grade of 0.2%. This clearly indicates that for a residence time of 10 minutes in the open rougher-scavenger circuit, higher aeration has a strong negative effect on the grade of MoS2 without improving recovery of MoS2.

The effect of residence time in the open rougher-scavenger circuit was investigated by analyzing the linear coded models obtained for 3, 6 and 10 minutes of cumulative float times. The data were analyzed on the basis of ratios of coefficients of airflow rate and degree of agitation, namely X1/X2 and degree of agitation and interaction of aeration and agitation, namely X2/X1X2.

It appears that higher agitation in the float cells increases the rate constant of fast-floating fraction but has no effect on slow-floating particles. The change in aeration rate has a more pronounced effect on the rate of fast-floating fraction but doesn’t effect the slow-floating fraction. Hence both variables, the degree of aeration and agitation, effect the rate of fast-floating particles with the degree of aeration having a greater effect. The rate of flotation of slow-floating component, which creates a problem in flotation was stable.