Since the petroleum crisis in 1973, the effect of the energy cost in the pellet production has been very severe with great risk to this economic activity. The countries that import petroleum, specially those under way of industrialization, felt a great impact in their payment balance due to the high expenses in oil.

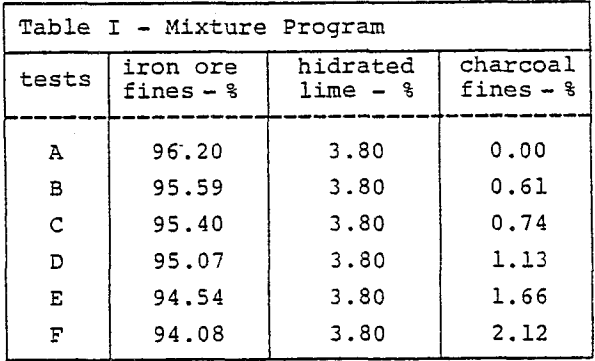

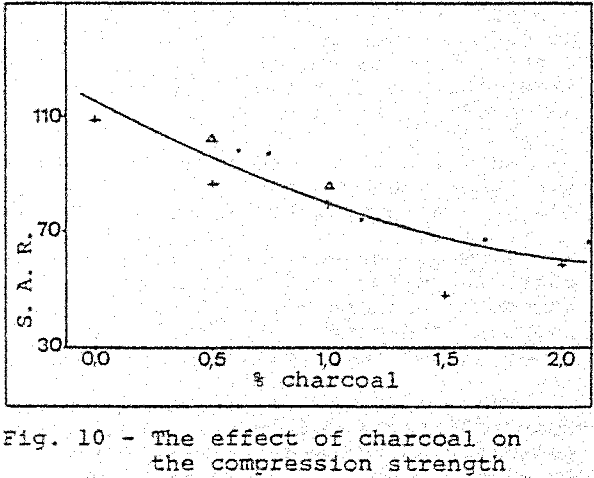

The testwork has been developed based on a serie of pot tests and checked by industrial production. In these pot tests charcoal has been dosed in increasing amounts and six levels of charcoal mixing were prepared.

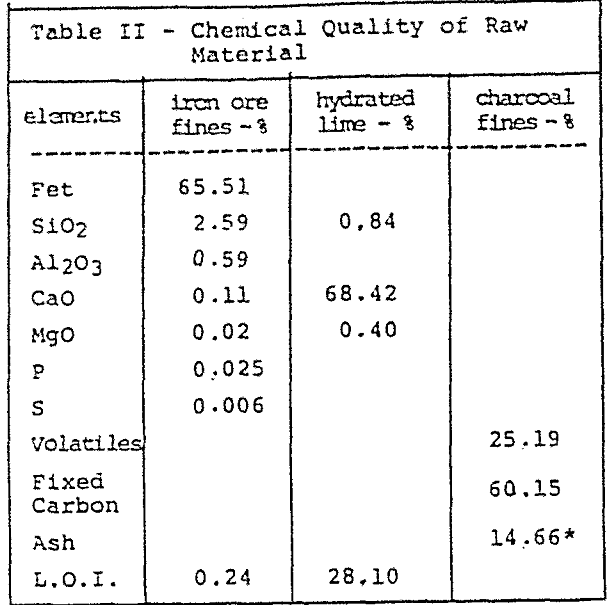

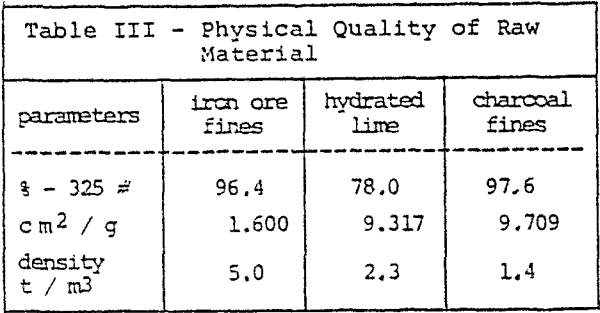

The charcoal was ground at two finesses: one 80% below 200 meshes and other 100% below 325 meshes. The binder used was the hydrated lime and the raw material was the current pellet feed for the CVRD pelletizing lines.

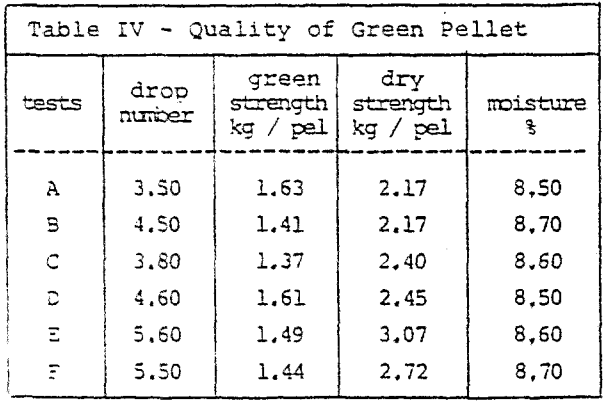

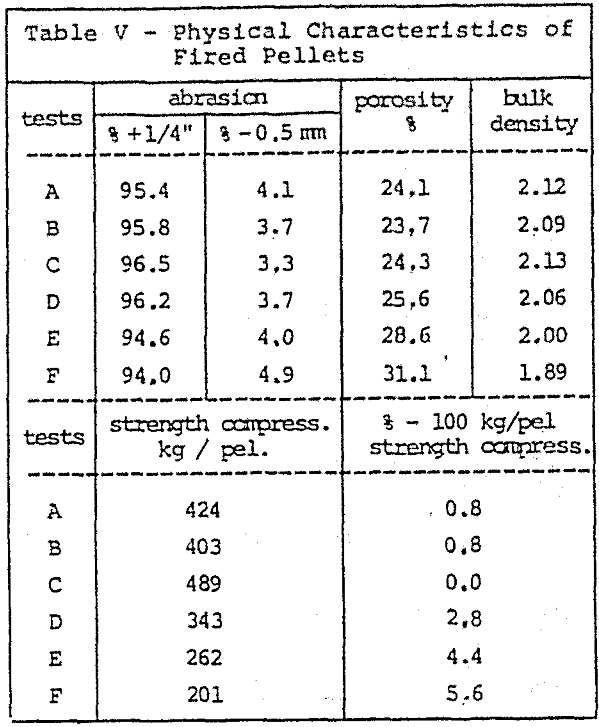

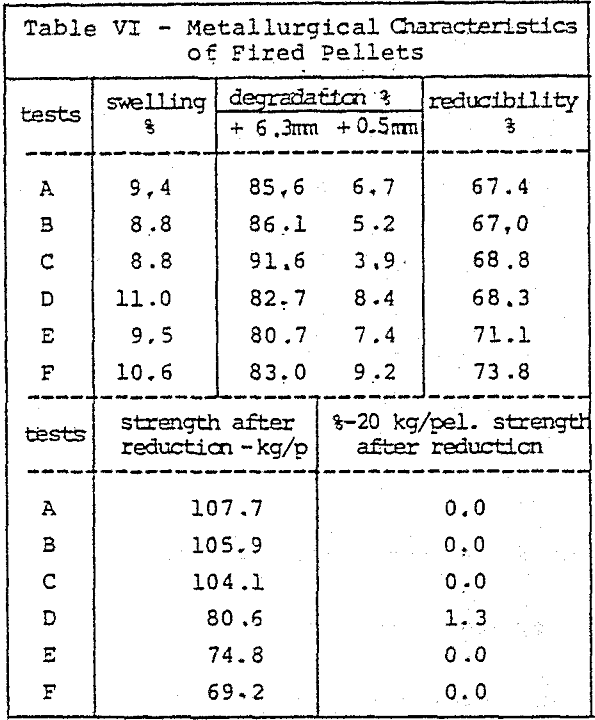

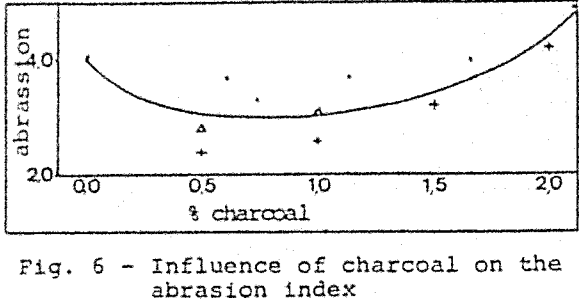

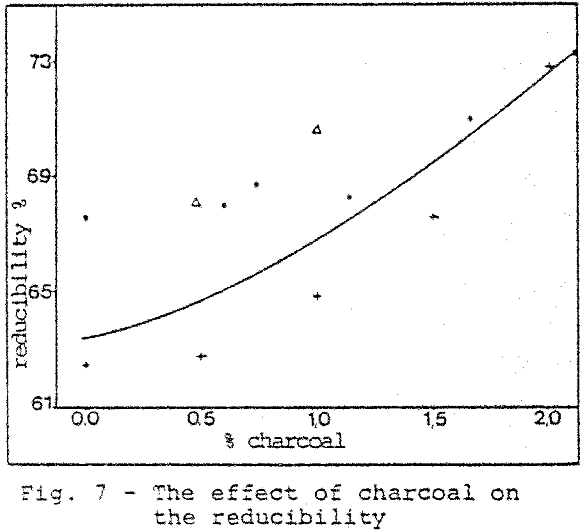

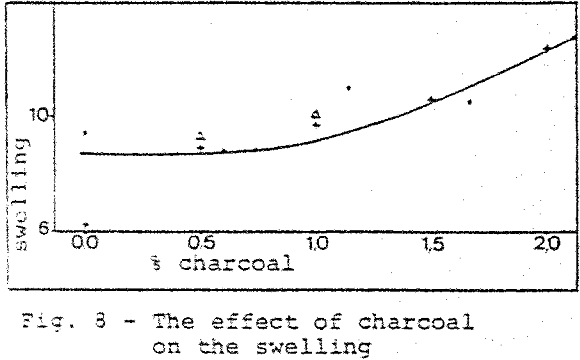

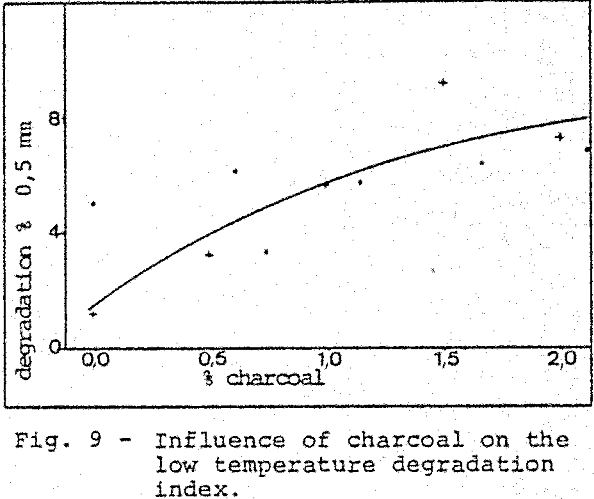

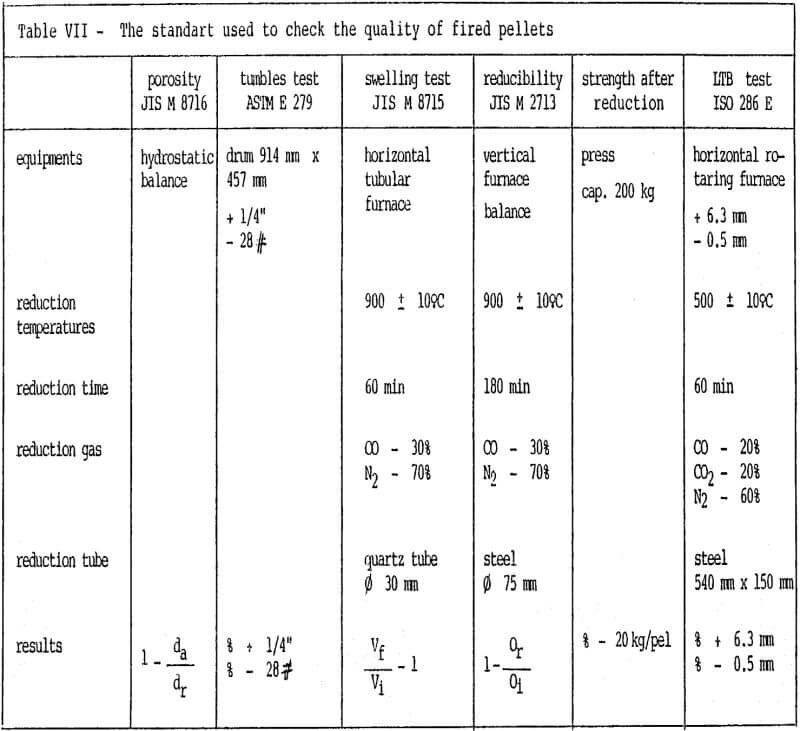

Tables below give the quality results of the pellets made with increasing dosing of charcoal.

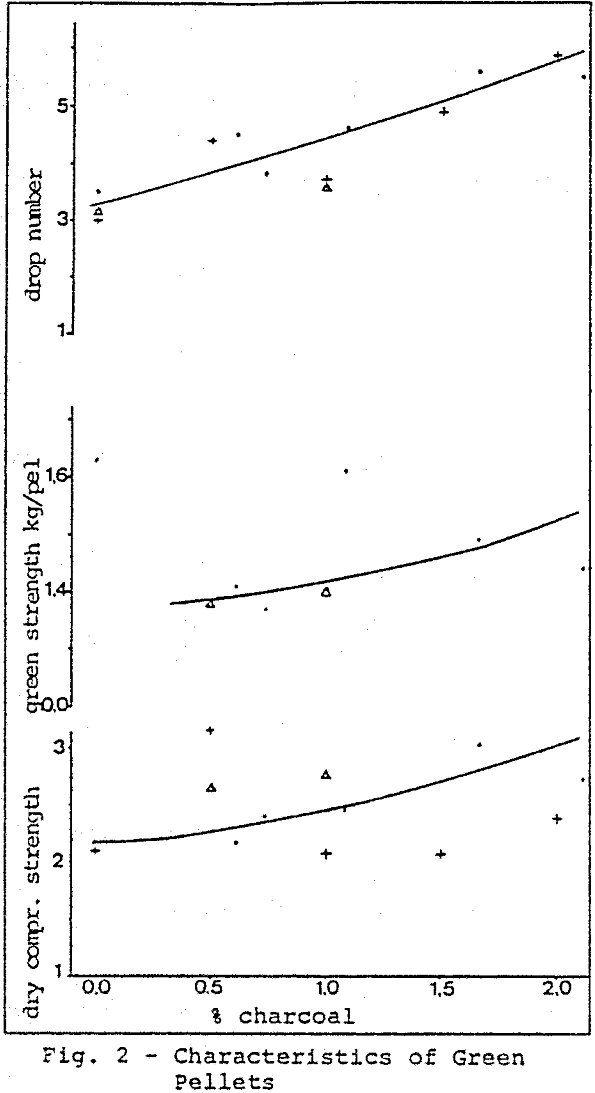

First of all one can see a positive effect of the charcoal on the green pellets characteristics, mainly on the drop number and dry compression strength.

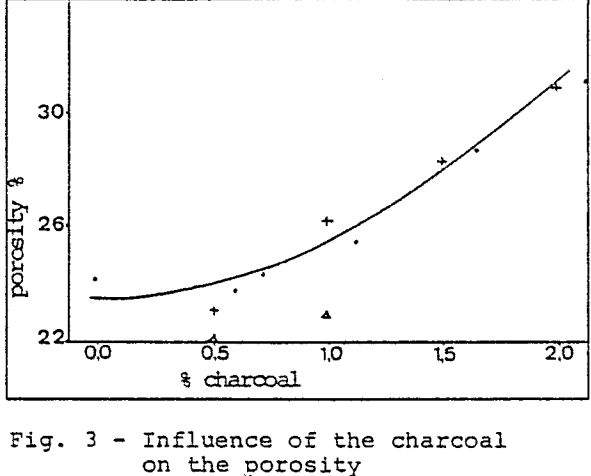

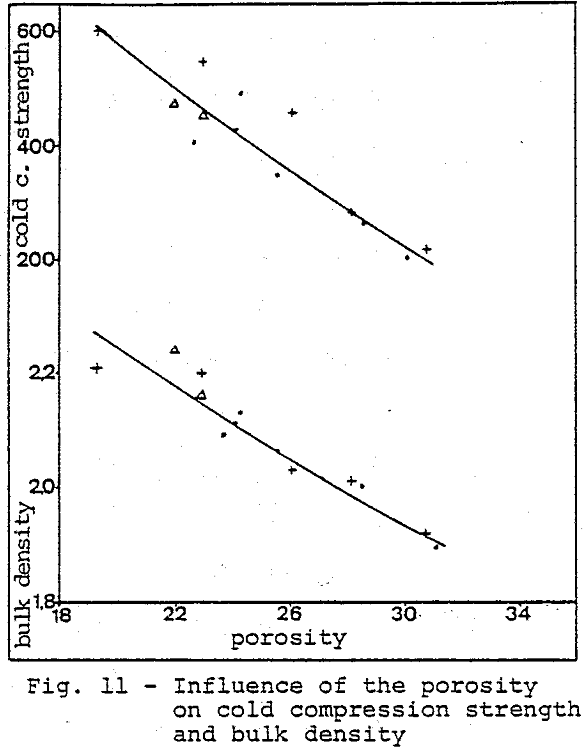

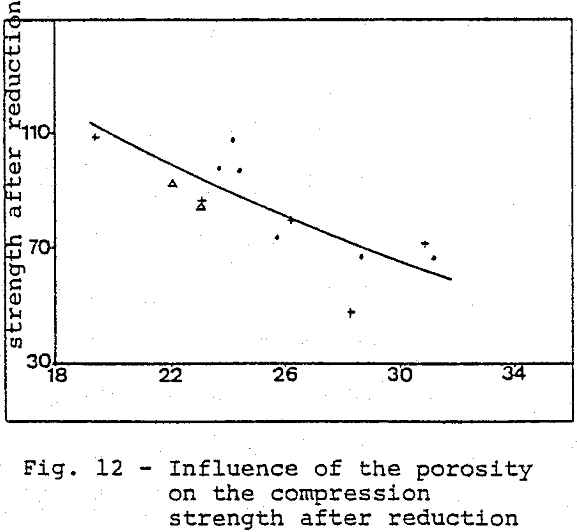

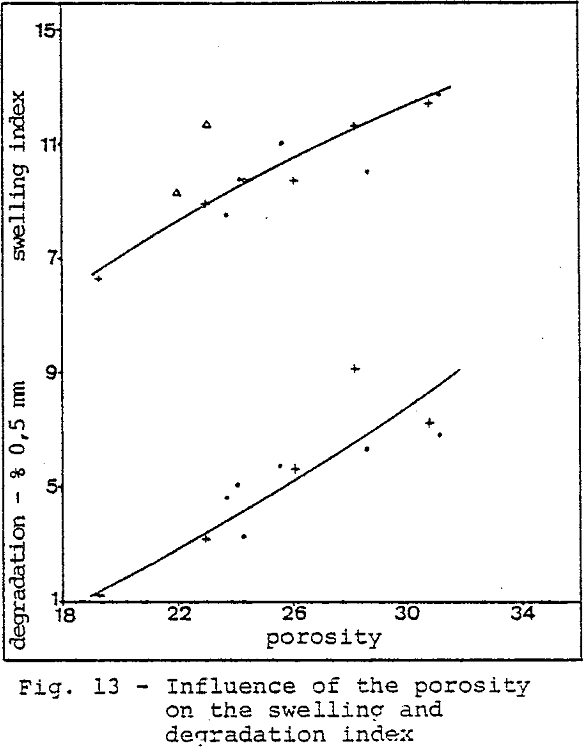

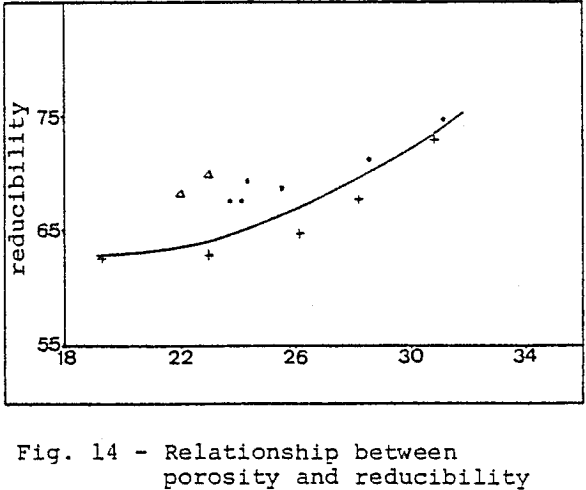

According to the testwork results, the effect of the charcoal on the porosity of the pellets is not significant till 0.8%, but beyond this level the porosity is very much affected.

Legend

da = apparent density

dr = tru density

Vf = volume after reduction

Vi = volume before reduction

Or = residual oxigen

Oi = initial oxigen