An air-pulsated jig has teen widely adopted as a main coal washer. It may be mainly because of its many technical and economic features such as large capacity, low running cost, long life, etc. However, the recent increasing demand of fuel coal requires a higher productivity and efficiency of the air-pulsated jig. To fill this requirement theoretical and experimental investigations have been conducted on model and practical jigs in Japan.

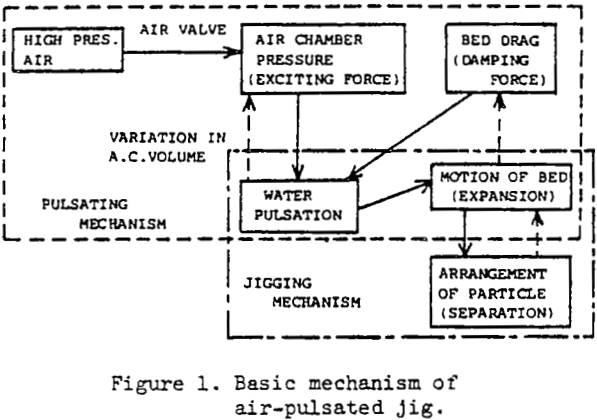

Reduced to its simplest terms, the air-pulsated jig essentially consists of two separate mechanisms: one of jigging which occurs in the jig bed; and the other of pulsating which causes the water pulsation.

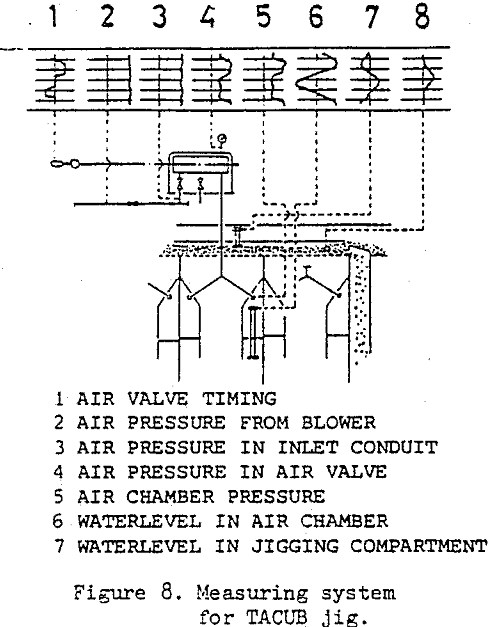

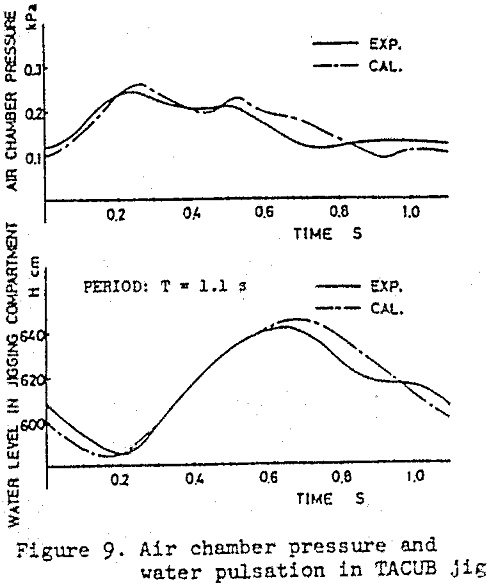

However, it should be noted that the relations between these major factors are complicated. For example, the air chamber pressure acting as an exciting force is inversely affected by the water pulsation. Hence, in order to fully understand the phenomena taking place in the air-pulsated jig it is necessary to take into account of such a feed back effect.

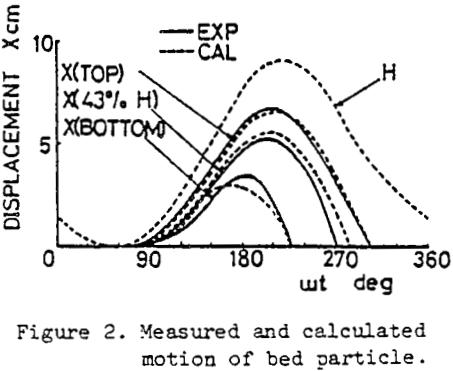

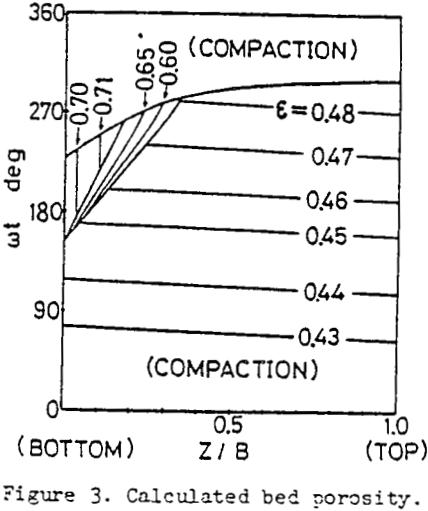

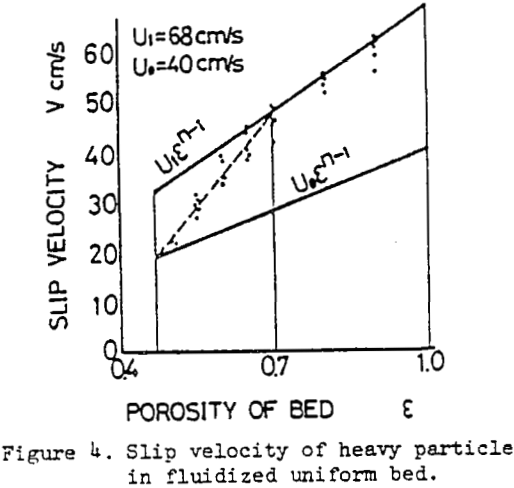

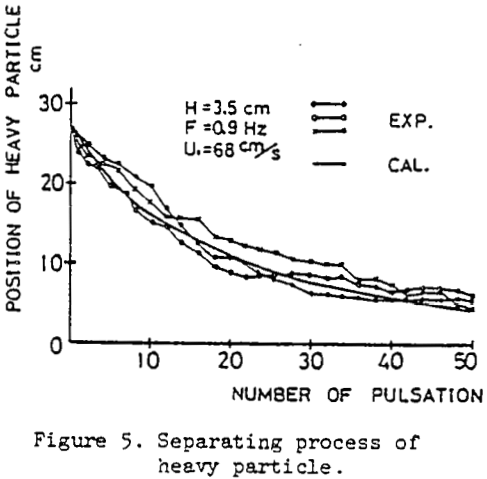

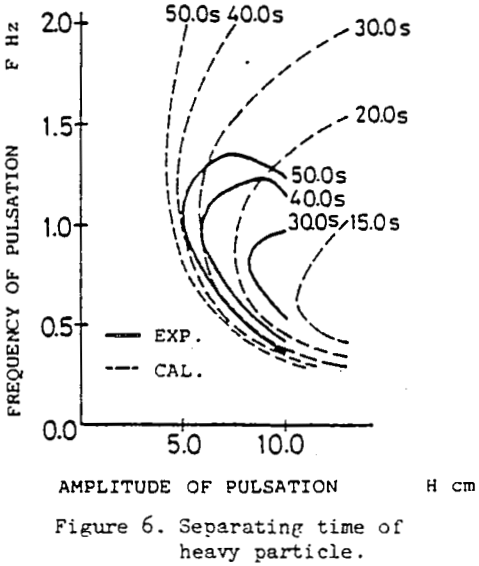

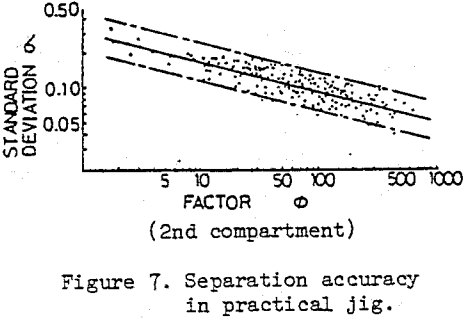

It is well known that the separation and stratification of particles in a jig are directly related to the bed expansion (mobility), which is governed by the water pulsation. In order to understand the basic relations between these factors theoretical and experimental investigations have been conducted on model jigs. Standard deviations on practical jigs have been also analyzed referring to the results obtained.

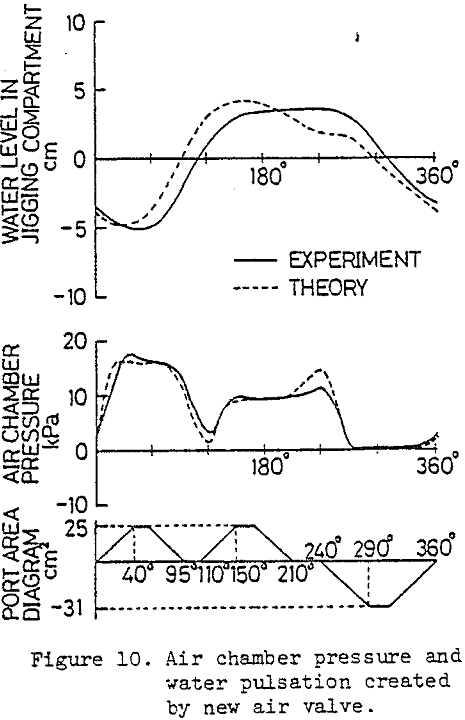

To obtain full mobility to very top layer it may be the most effective to adjust the wave pattern of the pulsation. For example, a good result has been observed in case of a trapezoidal wave pattern as recommended by Mayer and Aso. A device to reproduce such a wave pattern will be discussed later.

It is found that there exists an optimum frequency of pulsation for separation. Too high or too low frequency must be avoided because they cannot provide enough time nor mobility for separation. The optimum frequency may decrease with increasing the amplitude of the pulsation. But it should be noted that too large amplitude of the pulsation causes strong disturbance in the porosity of the bed and thus reduces stratification.

The pulsating mechanism in the air-pulsated jig has been theoretically analyzed in detail to understand the dynamic behavior of the water pulsation and to find a method to create efficiently the pulsation suited for coal washing.

In order to reproduce such a wave pattern suited for coal washing a new type of air valve has been developed. This new air valve is characterized by having one exhaust port and two inlet ports which admit high and low pressure airs separately.

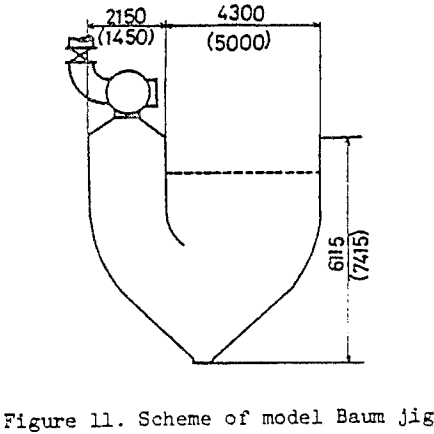

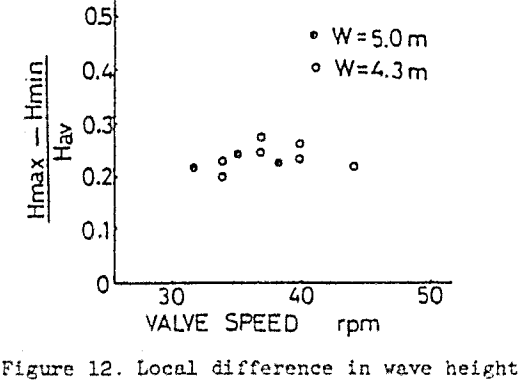

A Baum jig may be economical and easy to operate as compared with a TACUB or BATAC jig because it requires neither an additional air pressure nor a special control of the air valve to prevent the water from entering the air valve. A large Baum jig, however, has been considered to be very difficult to create an uni-form pulsation over the width of the bed.

Related: 8 of the best home garage air compressor

Related: 8 of the best home garage air compressor