The importance of the froth phase in establishing flotation performance has long been recognized. If the froth phase is insufficiently stable, mineralized bubbles which enter the froth layer rupture prematurely, causing valuable particles to drop back into the pulp. On the other hand, too stable a froth may result in nonselective entrainment of excessively large amounts of gangue particles which, in turn, reduces the product grade. Yet, despite the importance of the froth phase, relatively few studies have been conducted which examined the impact of froth behavior on the performance of column flotation cells.

Experimental

Samples of run-of-mine coal from the Illinois No. 6 and Pittsburgh No. 8 coal seams were used in the column flotation tests. The ash contents of the raw coal samples were 10.8% and 9.7%, respectively. The as-received samples were immediately crushed to -6 mm using a laboratory jaw crusher, then split into representative lots of approximately 1.5 kg each. The crushed samples were stored in a freezer at -20°C to minimize oxidation. Prior to flotation, the samples were dry pulverized in a laboratory hammermill to below 100 mesh. After grinding, the samples were diluted to 10% solids in a conditioning sump. A kerosene collector addition of 1 kg/t of feed coal was employed in all tests.

Results and Discussion

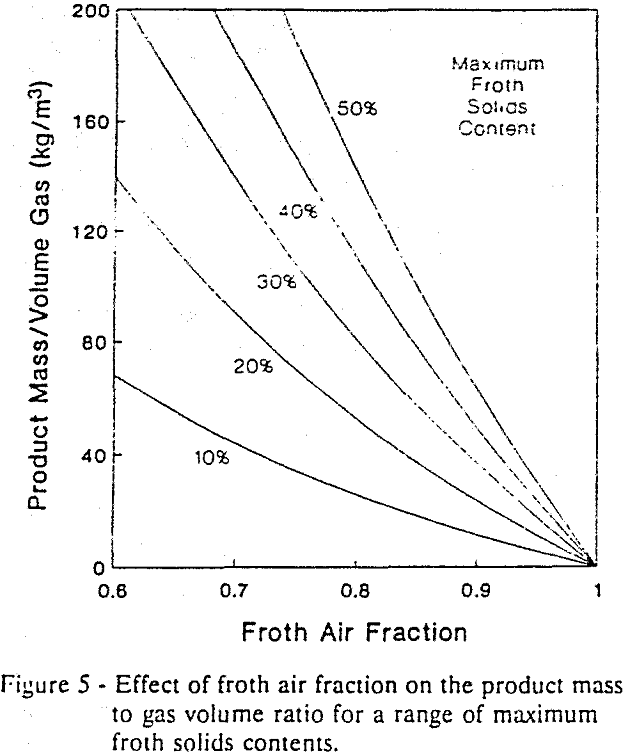

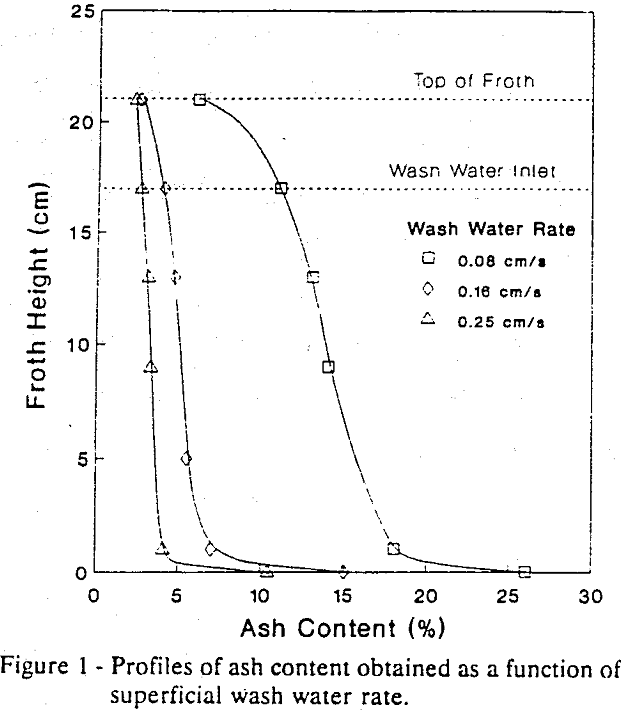

An abrupt decrease in the particle ash content occurs just above the pulp-froth interface. This upgrading can be largely attributed to the efficient cleaning action of the wash water which prevents the ash-bearing minerals from entering the base of the froth. For low wash water addition rates, ash content decreases slowly with height up to the wash water inlet (which is located 17 cm above the pulp). This section of the froth column is referred to as the stabilized froth zone since the flow of wash water through this zone retards bubble coalescence and stabilizes the froth. Bubbles in this zone are relatively uniform in size and coalesce very slowly

The ash profiles obtained at higher wash water rates remain relatively constant from the pulp-froth interface to the top of the froth. At these higher addition rates, hydraulic entrainment is largely eliminated at the pulp- froth interface and, as a result, no addition upgrading occurred in the drained froth.

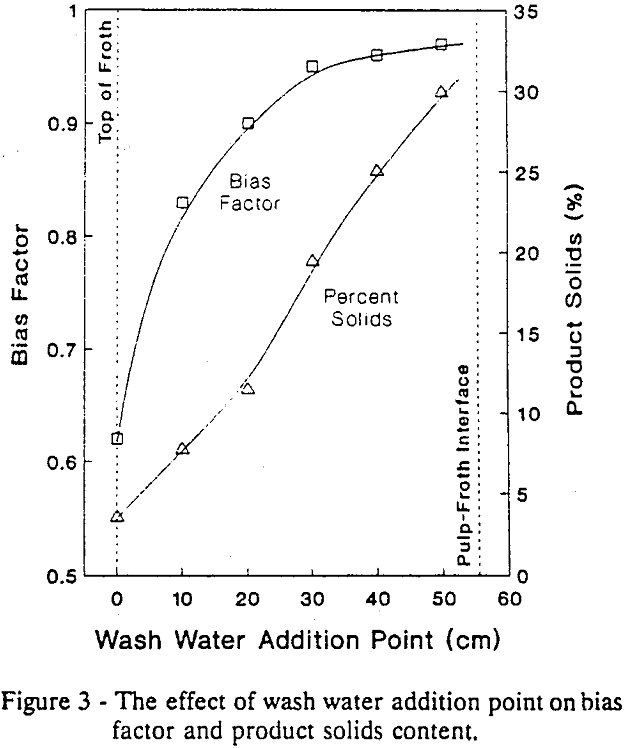

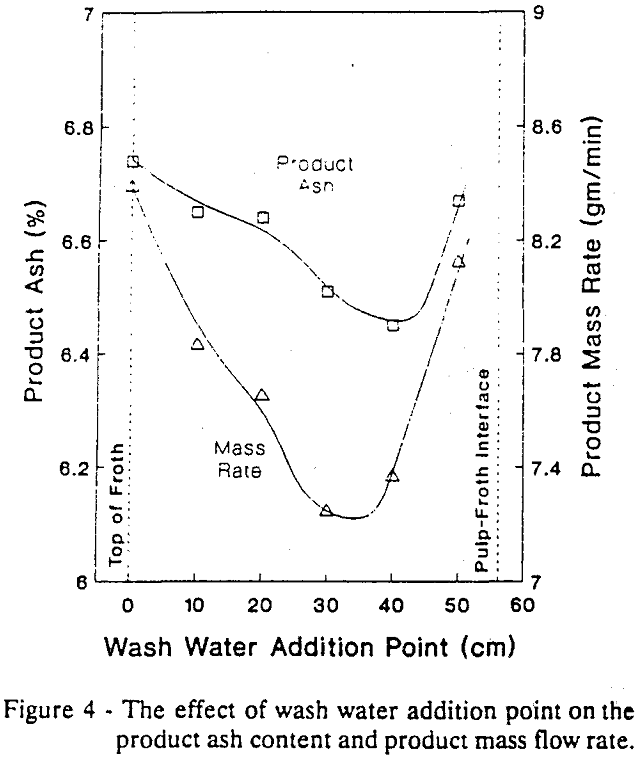

The ash content decreases as the wash water addition point is moved from the top of the froth down into the cell. The decrease in ash content can be largely attributed to an improvement in froth washing associated with the increased bias factor. However, as the addition point is moved closer to the pulp-froth interface, the stabilized froth zone becomes too short to effectively prevent the entrainment of fine particles.

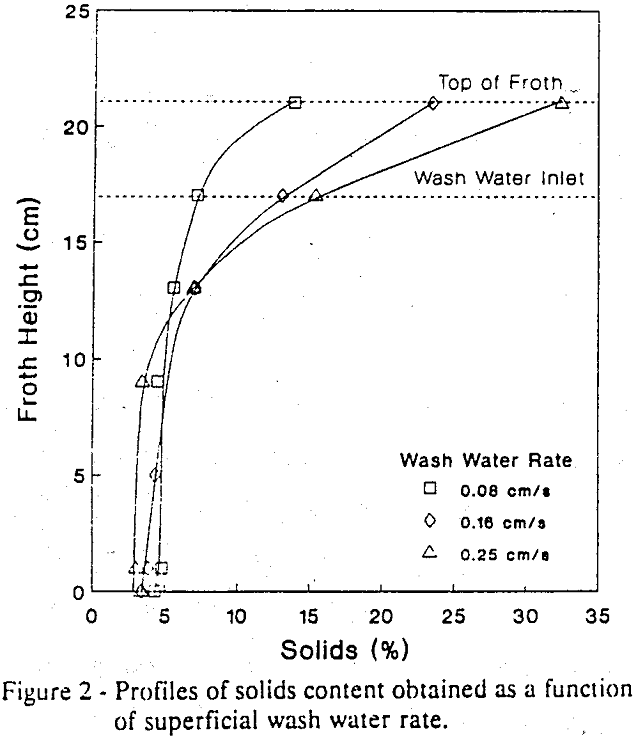

The test data collected in the present work indicates that if the froth phase in a column cell is allowed to drain excessively, the froth will be heavily loaded with solids and become unstable. This phenomenon, which is known as froth overloading, commonly occurs in conventional flotation cells that are operating with insufficient frother or at too low an air rate.